Soft package membrane for lithium battery

A flexible packaging film, lithium battery technology, applied in battery pack parts, battery box/jacket, battery box/cover material, etc. The effect of deep drawing performance and toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

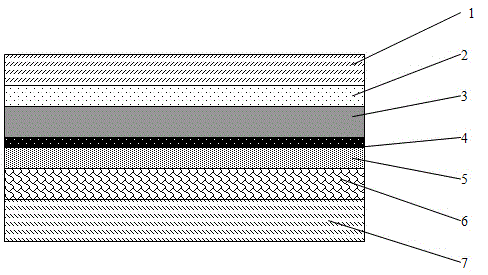

Image

Examples

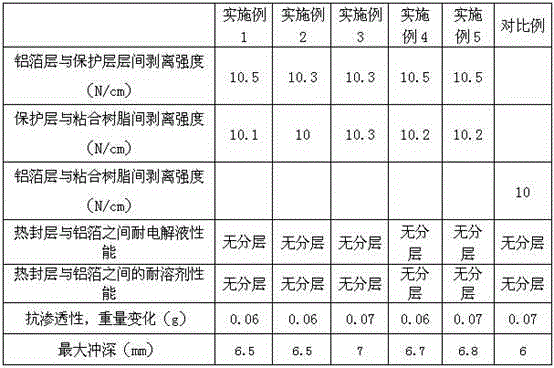

Embodiment 1

[0036] Coat dry thick 3 micron polyurethane adhesive on 15 micron nylon film, composite 30 micron aluminum foil after degreasing treatment, treat with phosphoric acid on the other side of aluminum foil to obtain anticorrosion treatment layer, coat 2 micron on the anticorrosion treatment layer 1.8% Glycidyloxypropylcyclopentyl-POSS? and 0.2% 1,2-Propanediol-Isobutyl-POSS? (Sigma-Aldrich) acrylic resin layer, on the other side of the acrylic resin layer, extrude 40 micron acid-modified polyethylene resin and compound 20 micron heat-sealing layer film, obtains the flexible packaging film of lithium battery, measures its performance and sees Table 1.

Embodiment 2

[0038]Coat dry thick 4 micron polyurethane adhesive on 20 micron nylon film, composite 50 micron aluminum foil after degreasing treatment, treat anticorrosion treatment layer with polyphosphoric acid on the other side of aluminum foil, coat 5 micron containing on the anticorrosion treatment layer Acrylic resin layer of 5% Epoxypropyl-Cyclopentyl-POSS? and 1.5% TMP Diol-Cyclo-pentyl-POSS? (Hybrid Plastics Company) by weight, extruding 40 microns of metal ion cross-linked polyolefin resin on the other side of the acrylic layer, The lithium battery flexible packaging film was obtained, and its properties were measured in Table 1.

Embodiment 3

[0040] Coat dry thick 5 micron polyurethane adhesive on 30 micron nylon film, composite 40 micron aluminum foil after degreasing treatment, treat anticorrosion treatment layer with pyrophosphoric acid on the other side of aluminum foil, coat 4 micron containing on the anticorrosion treatment layer A phenolic resin layer with 7.2% Glycidoxypropyl-POSS? and 0.7% trans-Cyclohexanediol-Isobuty-POSS? (Sigma-Aldrich) by weight, extruding 20 microns of metal ion cross-linked polyolefin resin on the other side of the phenolic resin layer and compounding 40 Micron heat-sealing layer film, obtain lithium battery flexible packaging film, measure its performance and see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com