An axisymmetric cross-finned heat exchange tube

An axisymmetric, heat exchange tube technology, applied in the field of heat exchange tubes, can solve the problems of inability to maximize the cross-section temperature field, difficult to ensure good contact of the outer tube, poor contact of the outer sleeve, etc. Field and cross-section temperature field uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in more detail below in conjunction with the accompanying drawings.

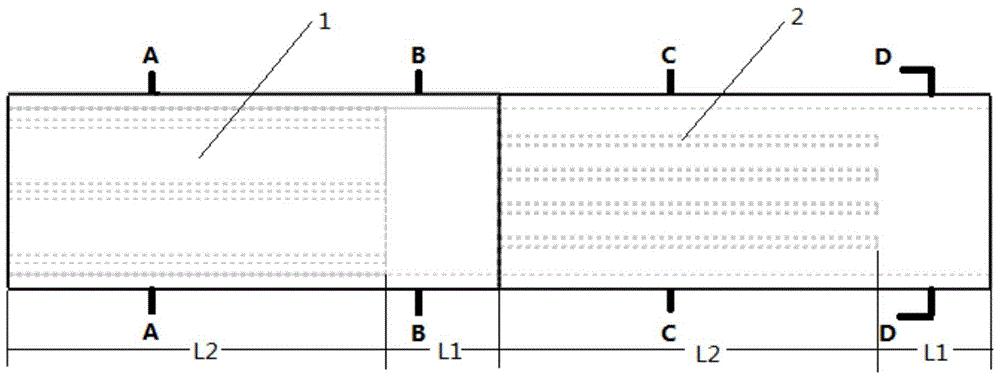

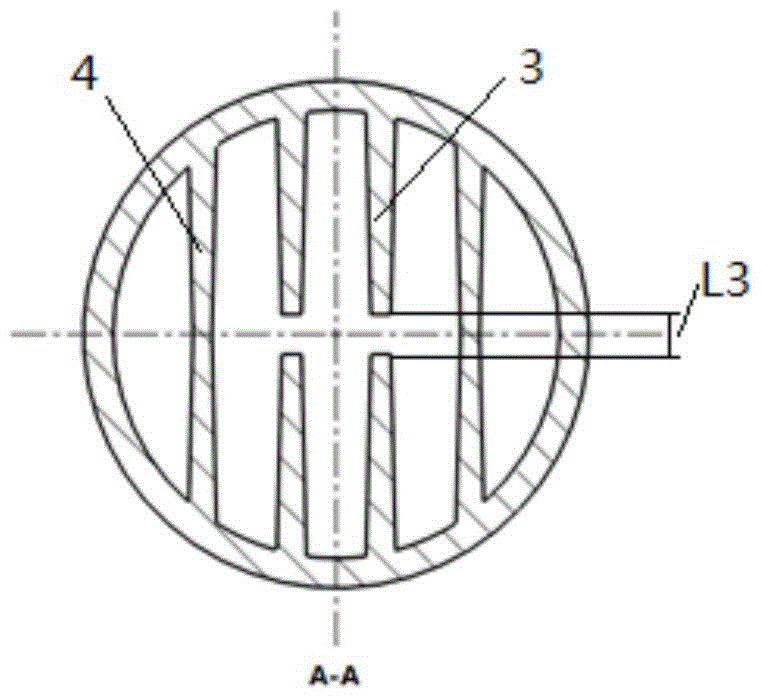

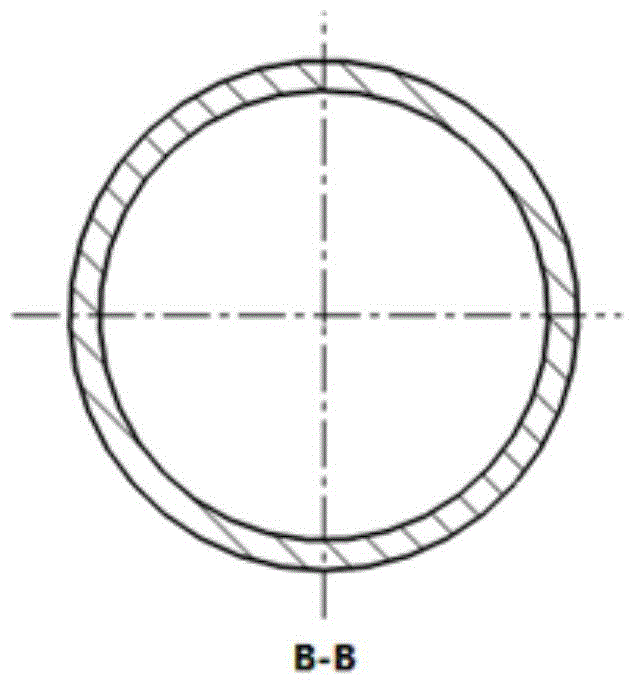

[0034] Such as Figure 1a , Figure 1b , Figure 1c , Figure 1d , Figure 1e and figure 2 As shown, the present invention is an axisymmetric cross-finned heat exchange tube, which includes a plurality of unit tubes 1 arranged at intervals and a rotating unit tube 2, the rotating unit tube 2 is rotated by the unit tube 1 at a preset angle made. The unit tube 1 is integrally connected with the side wall of the unit tube 1 along the axial direction, and there are multiple pairs of fins 3 facing up and down and wide fins 4 penetrating the cross section of the heat exchange tube. 1, the plurality of pairs of fins 3 are located between the wide fins 4 on the left and right sides, and each pair of fins 3 facing up and down is axisymmetric, and between the tops of each pair of fin plates 3 The distance is the preset distance L3, the design of fin 3 and wide fin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com