Full precast concrete stair sliding connecting system and construction method thereof

A prefabricated concrete, sliding connection technology, applied in stairs, building components, earthquake-proof and other directions, can solve the problems of the overall effect of the structure, the increase of the rigidity of the main structure, and the uneven distribution of the rigidity of the floor plane, so as to avoid rework and reduce the stiffness of the stairs. , the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings of the specification.

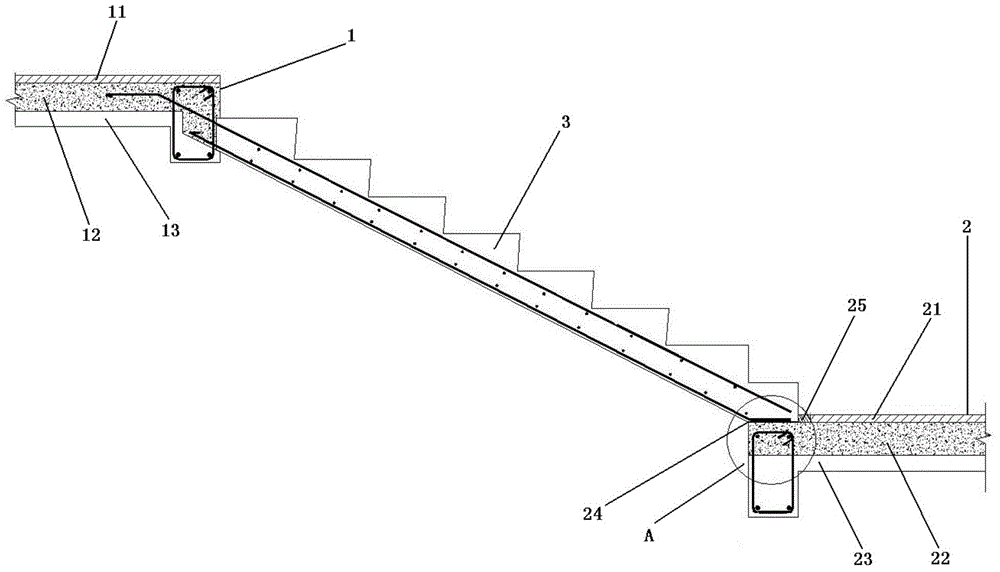

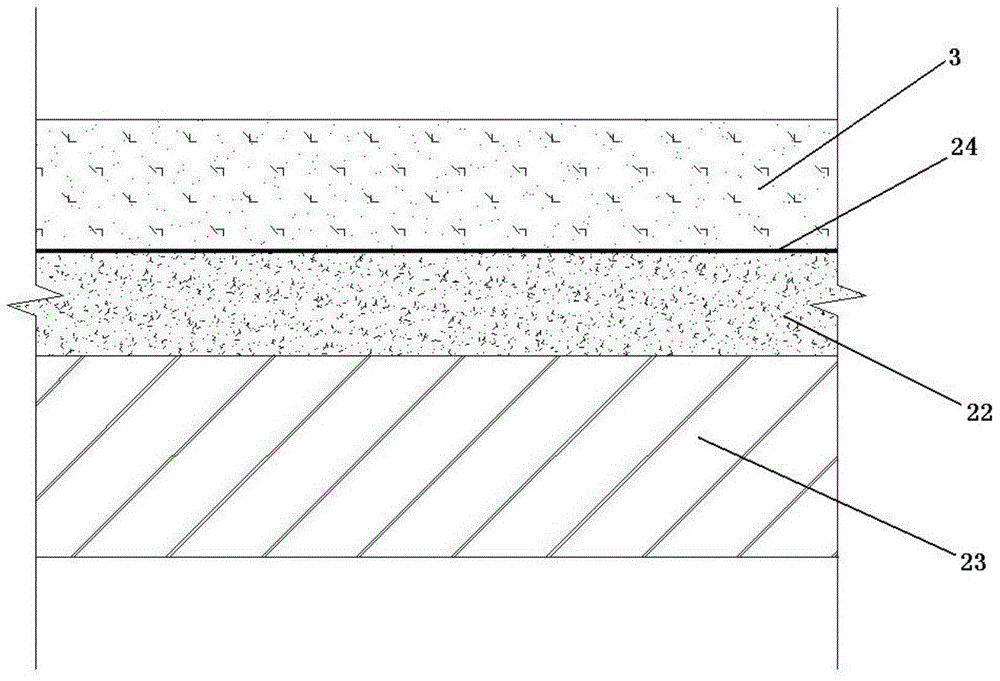

[0030] Such as figure 1 and figure 2 As shown, a fully precast concrete stair sliding connection system includes an upper laminated beam slab 1 and a lower laminated beam slab 2 as a rest platform, and a prefabricated staircase 3 as a step; the upper laminated beam slab 1 and the lower The width of the laminated beam slab 2 is the same as the step width of the prefabricated stair 3; the upper laminated beam slab 1 includes the upper building surface layer 11, the upper beam slab cast-in-place layer 12 and the upper beam slab precast layer from top to bottom 13; The lower laminated beam slab 2 includes a lower building surface layer 21, a lower beam slab cast-in-situ layer 22 and a lower beam slab prefab layer 23 from top to bottom.

[0031] Wherein, the top side end of the prefabricated staircase 3 is connected to the upper beam slab precast layer 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com