Variable-viscosity acid liquid used for acidifying processing

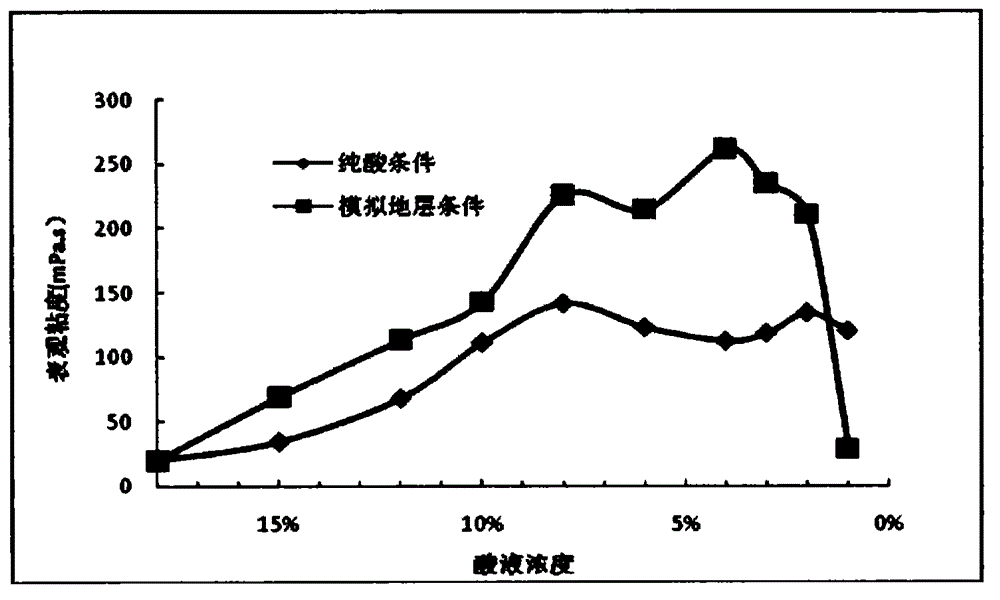

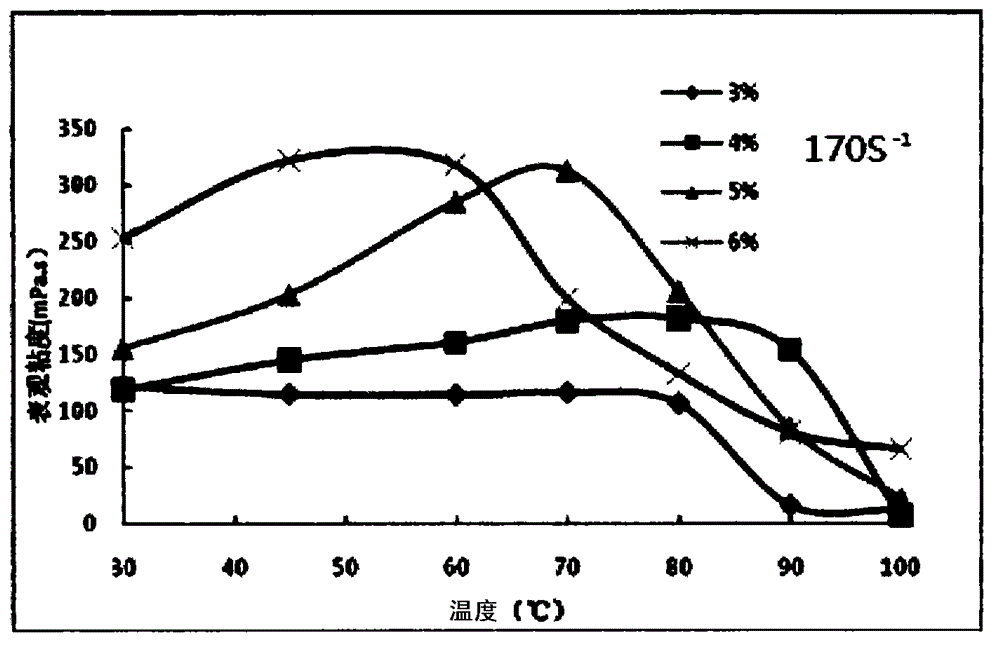

A technology of viscous acid and acidizing corrosion inhibitor, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and poor self-steering ability, achieve good temperature resistance and promote uniformity The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the viscosifying agent erucamidopropyl betaine.

[0031] Add 10 g of N,N-dimethylaminopropylamine, 11 g of erucic acid, and 0.1 g of catalyst KOH into a three-necked flask, the reaction temperature is 130° C., and the reaction time is 2 hours. After the reaction is finished, reduce the pressure and evacuate to 8-12kPa, and distill off excess dimethylaminopropylamine to obtain the intermediate product erucic acid amido tertiary amine. Take the intermediate product erucic acid amido tertiary amine and put it into a three-necked flask, add a mixed solvent, raise the temperature to the set temperature, then add aqueous sodium chloroacetate, stir and reflux, react at 60-90°C for 6-9 hours, and obtain a yellow to brown viscous liquid , after post-treatment is erucamide propyl betaine solid.

Embodiment 2

[0033] 1. Preparation of viscous acid solution: use hydrochloric acid, hydrofluoric acid, viscosifier, acidification corrosion inhibitor, iron ion stabilizer, demulsification aid, clay stabilizer and water to prepare viscous acid solution, viscous acid The weight percentage of each component in the liquid is as shown in Table 1 below:

[0034] Table 1 Embodiment 1 formula

[0035]

[0036] 2. During construction, inject pre-fluid, main acid, and displacement fluid into the formation in sequence according to the construction design.

[0037] 3. After the construction is completed, flow back according to the construction design.

Embodiment 3

[0039] 1. Preparation of viscous acid solution: use hydrochloric acid, hydrofluoric acid, viscosifier, acidification corrosion inhibitor, iron ion stabilizer, demulsification aid, clay stabilizer and water to prepare viscous acid solution, viscous acid The weight percentages of each component in the liquid are as shown in Table 2 below:

[0040] Table 2 Example 2 formula

[0041] Drug name

Mass (tons)

HCl

25.0

Erucamidopropyl Betaine

5.0

HF

2.5

HSJ-2 acidification corrosion inhibitor

1.0

[0042] Iron ion stabilizer for WC-1 acidification

1.0

DL-6 Broken L Drainage Aid

0.3

COP-1 clay stabilizer

1.0

Diethylene glycol butyl ether

2.0

water

62.2

[0043] 2. According to the construction design, inject the pre-fluid, main acid, and replacement fluid into the bottom layer in sequence during construction.

[0044] 3. After the construction is completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com