Polymer composite asphalt and preparation method thereof

A composite asphalt and polymer technology, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problem that the modification effect of chemical modifiers cannot be fully exerted, the preparation method is not applicable, and the actual use of chemically modified asphalt is limited. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

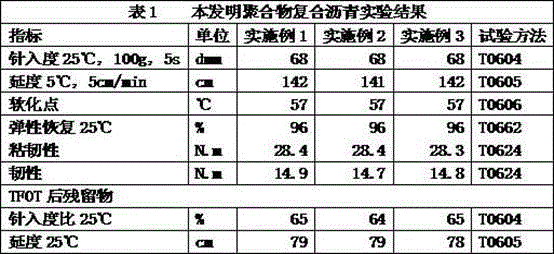

Embodiment 1

[0014] Example 1: (1) Take 0.4 kg of acryloyloxyethyltrimethylammonium chloride, 1.3 kg of lauryl amidopropyl betaine, and 9 kg of water and mix them uniformly at a temperature of 60-70°C;

[0015] (2) Heat 80 kg of No. 90 petroleum asphalt to 110-120 ° C, then add 0.6 kg of dibenzoyl peroxide, 7.5 kg of butane tetracarboxylic acid, 10 kg of polyalphaolefin, 5.5 kg of polyvinyl alcohol, 2500 mesh 2.5 kg of sericite powder, stirred for 80 to 90 minutes at a speed of 400 to 600 rpm;

[0016] (3) Add 5 kg of 1250-mesh sericite powder, 2.5 kg of 600-mesh sericite powder, and 2.5 kg of ethylenediaminetetraacetic acid into the mixture in step (2), and stir at 800-1000 rpm for 20-25 minute;

[0017] (4) Add the mixture in step (1) to the mixture in step (3), and stir at 600-800 rpm for 35-45 minutes under the condition of 120-130° C. to obtain the product.

Embodiment 2

[0018] Example 2: (1) Take 0.4 kg of acryloyloxyethyltrimethylammonium chloride, 1.2 kg of lauryl amidopropyl betaine, and 8 kg of water and mix them uniformly at a temperature of 60-70°C;

[0019] (2) Heat 77 kg of No. 90 petroleum asphalt to 110-120 ° C, then add 0.6 kg of dibenzoyl peroxide, 6 kg of butane tetracarboxylic acid, 9 kg of polyalphaolefin, 5 kg of polyvinyl alcohol, 2500 mesh 2 kg of sericite powder, stirred at 400-600 rpm for 80-90 minutes;

[0020] (3) Add 4 kg of 1250-mesh sericite powder, 2 kg of 600-mesh sericite powder, and 2 kg of ethylenediaminetetraacetic acid to the mixture in step (2), and stir at 800-1000 rpm for 20-25 minute;

[0021] (4) Add the mixture in step (1) to the mixture in step (3), and stir at 600-800 rpm for 35-45 minutes under the condition of 120-130° C. to obtain the product.

Embodiment 3

[0022] Example 3: (1) Take 0.5 kg of acryloyloxyethyltrimethylammonium chloride, 1.5 kg of lauryl amidopropyl betaine, and 9 kg of water and mix them uniformly at a temperature of 60-70°C;

[0023] (2) Heat 84 kg of No. 90 petroleum asphalt to 110-120 ° C, then add 0.8 kg of dibenzoyl peroxide, 8 kg of butane tetracarboxylic acid, 11 kg of polyalphaolefin, 6 kg of polyvinyl alcohol, 2500 mesh 3 kg of sericite powder, stirred at 400-600 rpm for 80-90 minutes;

[0024] (3) Add 6 kg of 1250-mesh sericite powder, 3 kg of 600-mesh sericite powder, and 3 kg of ethylenediaminetetraacetic acid into the mixture in step (2), and stir at 800-1000 rpm for 20-25 minute;

[0025] (4) Add the mixture in step (1) to the mixture in step (3), and stir at 600-800 rpm for 35-45 minutes under the condition of 120-130° C. to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com