Vinyl ester resin and preparation method thereof

A vinyl ester resin and vinyl ester functional technology, which is applied in the field of vinyl ester resin and its preparation, can solve the problems such as the large influence of moisture, and achieve the effect of overcoming the curing problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In the preparation method of the vinyl ester resin of the present invention, the equivalent ratio of the compound containing the epoxy resin structure to the unsaturated monocarboxylic acid is preferably 1:0.8-1.2, more preferably 1:0.9-1.1.

[0052] The compound containing epoxy resin structure can be bisphenol A type epoxy resin (Bisphenol A Epoxy Resin), bisphenol F type epoxy resin (Bisphenol F Epoxy Resin), novolac type epoxy resin (Novolac Type Epoxy Resin) ), Tetrabromo-Bisphenol A Epoxy Resin (Tetrabromo-Bisphenol A Epoxy Resin), one or more combinations, but not limited to the above options.

[0053] In the above-mentioned ring-opening polymerization step, as long as the compound containing the epoxy resin structure and the unsaturated monocarboxylic acid can be used for ring-opening polymerization, the polymerization conditions are not particularly limited, but preferably 90 Polymerization at ~130°C for 2 to 6 hours.

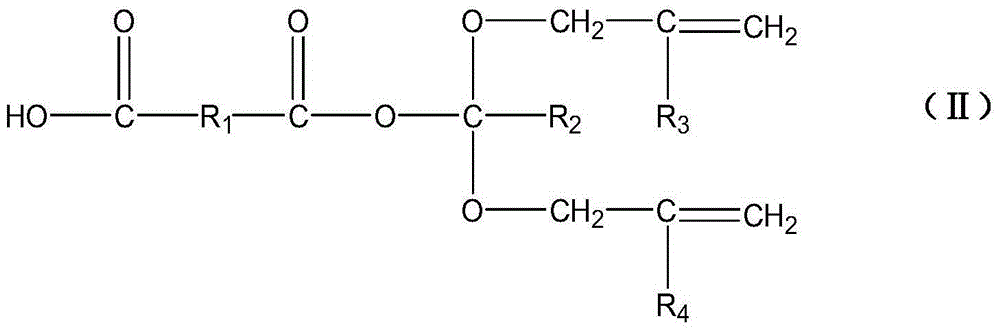

[0054] The vinyl ester resin of the pres...

Embodiment 1

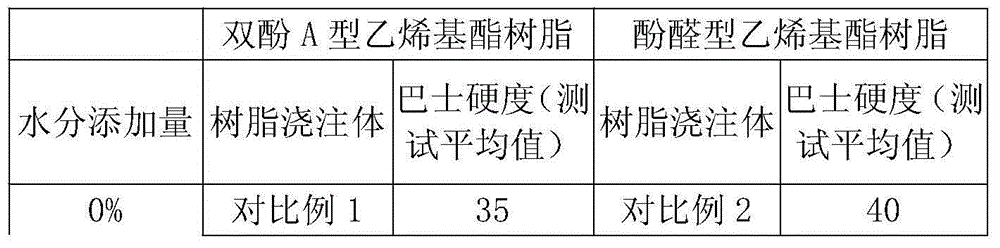

[0062] Use bisphenol A epoxy resin and unsaturated monocarboxylic acid to carry out ring-opening polymerization reaction, and its equivalent ratio is bisphenol A epoxy resin: special unsaturated monocarboxylic acid: methacrylic acid=1.0:0.9:0.1; its reaction The compound is then diluted with styrene, the styrene content is 45%, and the prepared bisphenol A vinyl ester resin.

Embodiment 2

[0064]Use bisphenol A epoxy resin and unsaturated monocarboxylic acid to carry out ring-opening polymerization reaction, and its equivalent ratio is bisphenol A epoxy resin: special unsaturated monocarboxylic acid: methacrylic acid=1.0:0.6:0.4; its reaction The compound is then diluted with styrene, the styrene content is 45%, and the prepared bisphenol A vinyl ester resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com