Water-based quick drying painting and preparation method thereof

A fast-drying coating and water-based technology, applied in the field of coatings, can solve the problems of affecting the color of decorative coatings, affecting the appearance quality of coatings, and hindering the diffusion of water vapor, so as to shorten the curing cycle of coatings and reduce the migration and drying of moisture to the outside. Process, the effect of improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0024] A preparation method for water-based quick-drying paint, comprising the steps of:

[0025] 1), prepare the pigment (color paste) by water-based resin and pigment in proportion;

[0026] 2) Mix resin, color paste, filler, defoamer, leveling agent, wetting agent and water in proportion and stir evenly;

[0027] 3) Before the coating operation, add the anti-corrosion quick-drying inorganic film-forming agent (sodium dihydrogen phosphate mixed with phosphogypsum powder) and the dispersant into the resulting mixture and stir rapidly for 10 minutes to obtain the water-based quick-drying coating.

Embodiment 3-4

[0029] A preparation method for water-based quick-drying paint, comprising the steps of:

[0030] 1), prepare the pigment (color paste) by water-based resin and pigment in proportion;

[0031] 2) Mix resin, color paste, filler, defoamer, leveling agent, wetting agent and water in proportion and stir evenly;

[0032] 3) Before the coating operation, add the anti-corrosion and quick-drying inorganic film-forming agent (phosphate system, such as Zhongshan Kebang's phosphate, grade 9800) and dispersant to the resulting mixture and stir quickly for 15 minutes to obtain a water-based quick-drying coating .

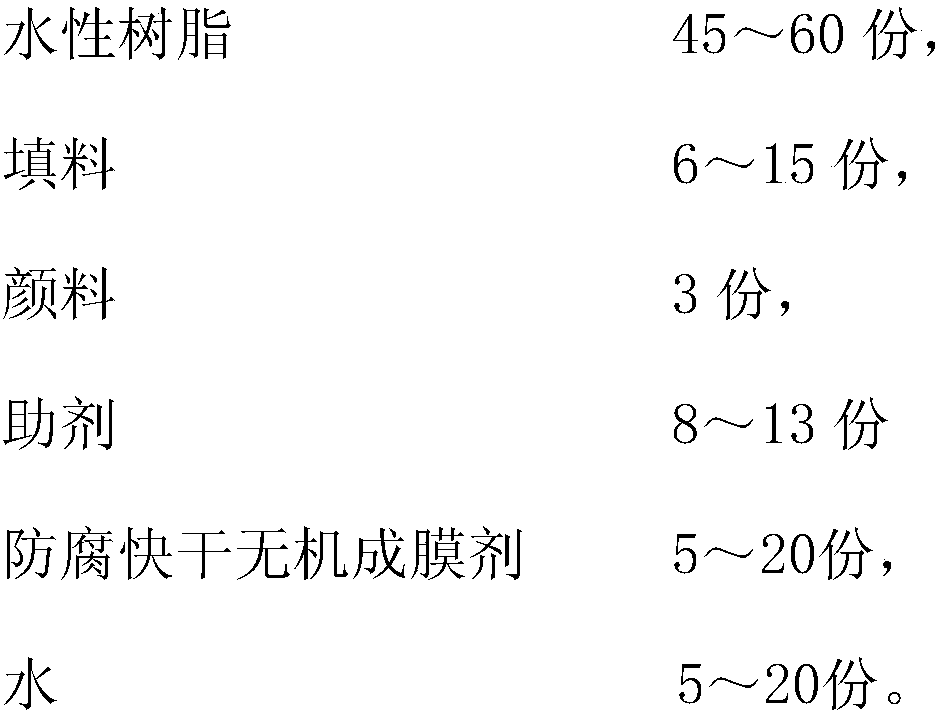

[0033] Table 1: The distribution ratios of each group in Embodiment 1-4

[0034]

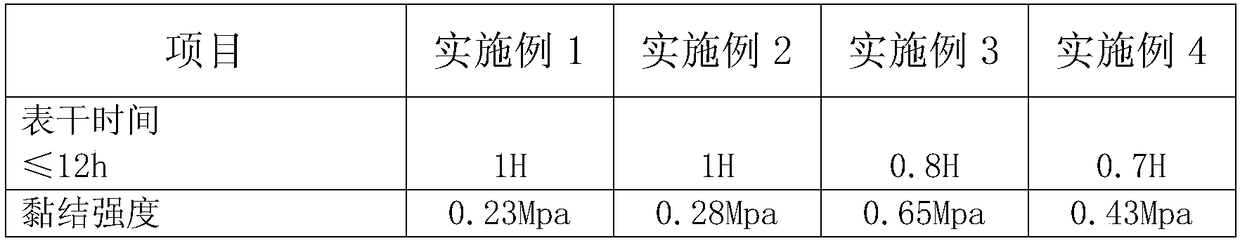

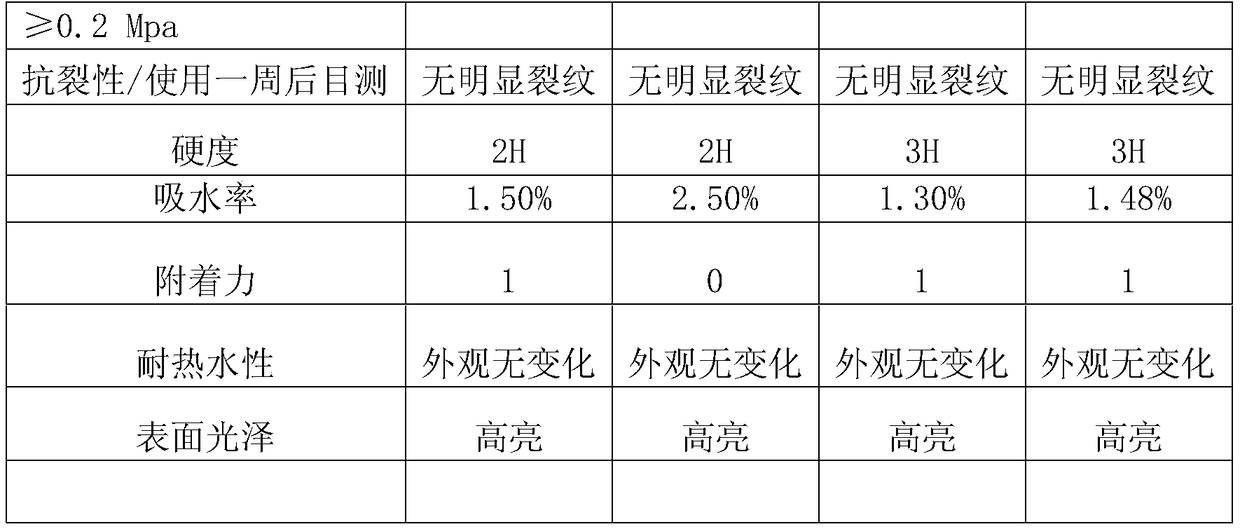

[0035] Embodiment 1~4 gained water-based quick-drying paint actual test data

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com