Air-assisted hydraulic air booster pump for magnetically levitated train

A technology of magnetic levitation trains and gas top fluid, which is applied to vehicle components, brakes, transportation and packaging, etc., can solve the problems of no guide device for the gas piston, unilateral wear and easy falling off of the gas piston apron, and improve reliability and Long service life, avoid shedding and wear, avoid the effect of unilateral wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

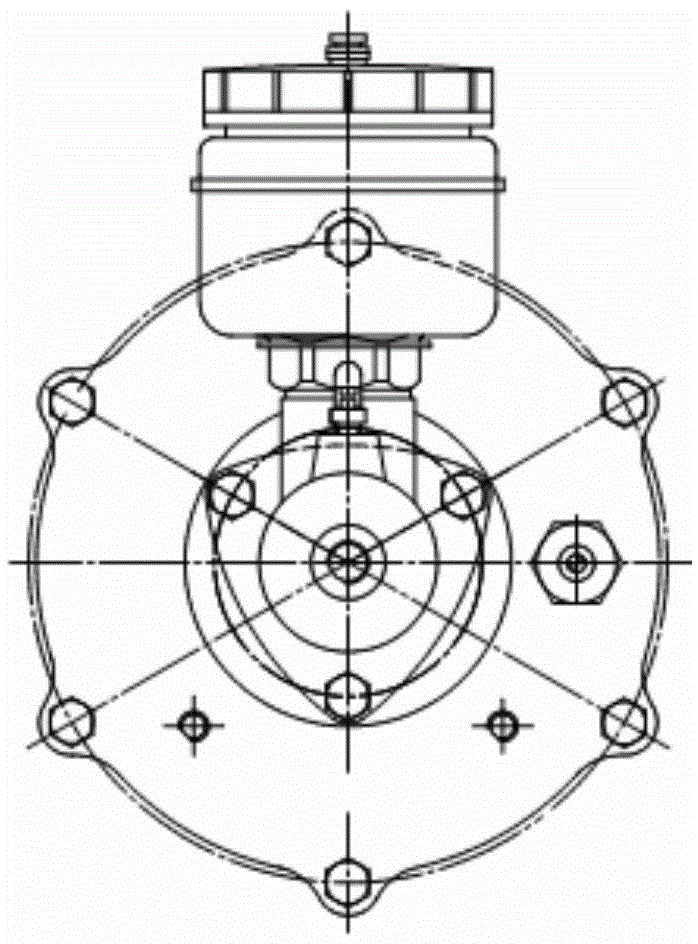

[0027] Such as Figure 5 , Figure 6 The structure of the present invention shown is a gas-top-liquid air booster pump for maglev trains, also known as CXF614 air booster pump. Connection relationship of the present invention: the air booster pump air inlet is connected with the air brake valve (an original valve in the system) air outlet, and the oil outlet is connected with the brake oil inlet.

[0028] The air booster pump includes a cylinder block assembly 1, an air piston 2, a hydraulic cylinder block 9, and a hydraulic piston assembly 11; the cylinder block assembly 1 and the hydraulic cylinder block 9 are tightly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com