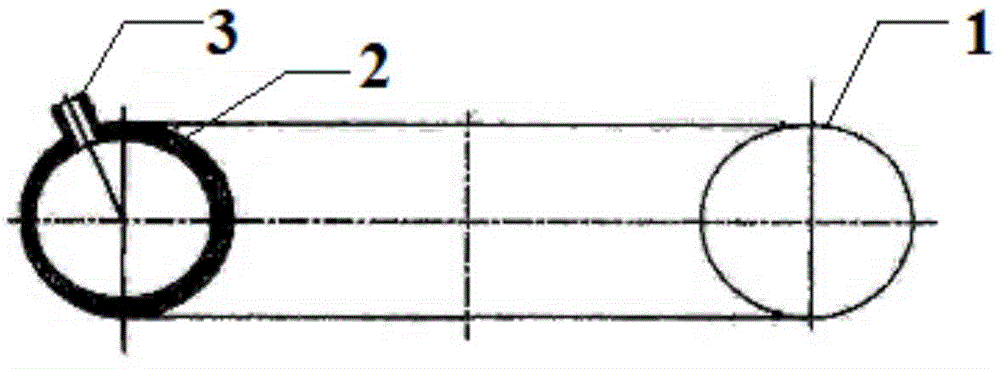

Preparation method of metal lining ring-shaped composite cylinder

A metal-lined, ring-shaped technology, applied in the field of composite high-pressure gas cylinders, can solve the problems of poor manufacturability of reinforced materials, spot chemical corrosion, etc., and achieve the effects of excellent fatigue performance, low cost, and comprehensive mechanical properties of the gas cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

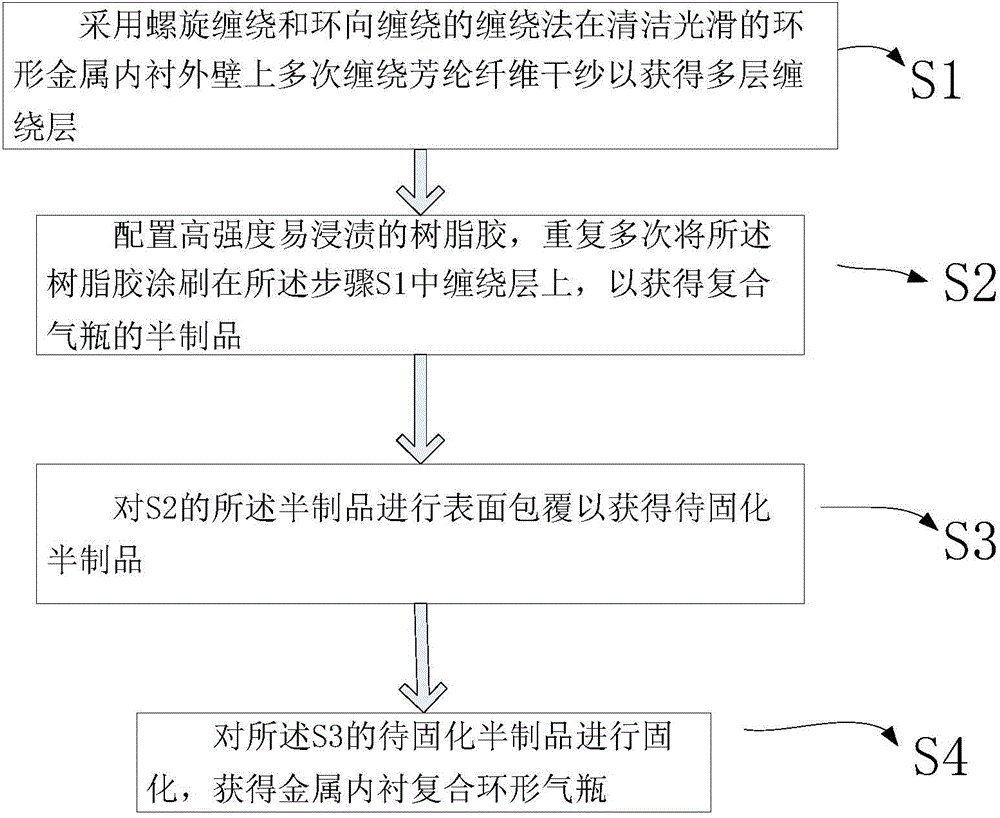

[0028] S1: Helical winding and hoop winding methods are used to wind heterocyclic aramid fiber dry yarns on the outer wall of a clean and smooth annular metal lining multiple times to obtain multiple winding layers. Among them, the heterocyclic aramid fiber is Russian aramid fiber APMOC, with a linear density of 800tex. When winding, the dry yarn is first poured onto the small thread spool, and then the small thread spool is installed on the ring cylinder winding machine, and then the dry The yarn is ply wound onto a titanium alloy lining. Before winding, the surface of the titanium alloy lining is uniformly sandblasted and cleaned with alcohol. The winding helical layer is alternately wound with 5 tangent points and 6 tangent point lines, the number of layers of the helical layer is 10 layers, and the number of layers of the hoop winding layer is 4 layers.

[0029] S2: Prepare high-strength and easy-to-impregnate resin glue, and repeatedly paint the resin glue on the multi-l...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1, the difference is:

[0035] S1: The linear density of the heterocyclic aramid fiber is 300tex.

[0036] S2: High-strength and easy-to-impregnate resin glue formula and the mass ratio of each formula is epoxy resin TDE-85: epoxy resin EP01441-310: methyltetrahydrophthalic anhydride: imidazole = 0.2: 0.3: 0.7: 0.02, when applying glue The temperature of the resin glue is 60°C, and the mass ratio of the resin glue consumed by the first glue brushing, the second glue brushing and the third glue brushing is 2.2:1.3:0.5. After the first brushing, keep it in an oven at 70°C for 10 minutes. Then carry out the second glue brushing, the second glue brushing time is 15min, the glue brushing method and baking method are the same as the first glue brushing. Finally, apply glue for the third time, and the glue brushing time is 10 minutes. The glue brushing method and baking method are the same as the first time. After three times of gluin...

Embodiment 3

[0039] This embodiment is the same as Embodiment 1, the difference is:

[0040] S1: The linear density of the heterocyclic aramid fiber is 500tex.

[0041] S2: High-strength and easy-to-impregnate resin glue formula and the mass ratio of each formula is epoxy resin TDE-85: epoxy resin EP01441-310: methyltetrahydrophthalic anhydride: imidazole = 0.4: 0.15: 0.55: 0.01, when applying glue The temperature of the resin glue is 70°C, and the mass ratio of the resin glue consumed by the first glue brushing, the second glue brushing and the third glue brushing is 2.4:1.5:0.7. After the first brushing, keep it in an oven at 60°C for 50 minutes. Then carry out the second glue brushing, the second glue brushing time is 15min, the glue brushing method and baking method are the same as the first glue brushing. Finally, apply glue for the third time, and the glue brushing time is 10 minutes. The glue brushing method and baking method are the same as the first time. After three times of g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com