Anti-static foamed blown film and forming method

A technology of blown film and molding method, applied in the direction of static electricity, electrical components, etc., can solve the problems of secondary pollution of protective screen, leakage of antistatic agent, etc., and achieve good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

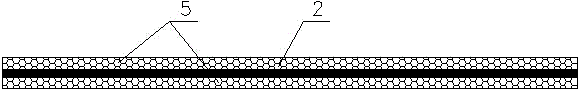

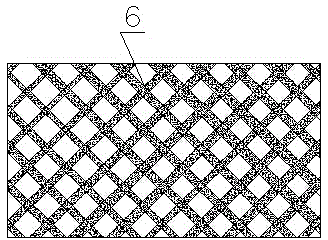

[0012] Embodiment 1: with reference to attached figure 1 and figure 2 . An antistatic foamed blown film, comprising a foamed blown film 5, the film surface of the foamed blown film 5 blends with the film surface, and a layer of metal powder particles 2 is laid between the surfaces. The metal powder particle layer formed by the metal powder particles 2 has a network structure 6 . The metal powder 2 is aluminum powder, copper powder, copper alloy powder.

Embodiment 2

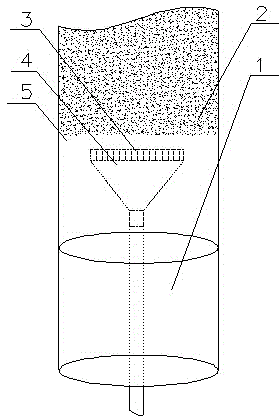

[0013] Embodiment 2: with reference to attached image 3 . On the basis of Example 1, a method for forming an antistatic foamed blown film includes a blown film machine, and the melted plastic raw material is extruded from the die mouth 1, and while the plastic film is inflated, it is positioned at the die head The metal powder nozzle 4 above the die mouth sprays the metal powder from the nozzle and adheres to the surface of the molten foamed blown film, then closes the mold, cools, and then winds up an anti-static foamed blown film through the winding rack. Film cartridges. The metal powder nozzle 4 is a partial mouth, and the partial mouth is provided with a plurality of mouth openings 3 at equal intervals.

Embodiment 3

[0014] Embodiment 3: with reference to attached image 3 . An antistatic foam blown film forming equipment includes a blown film machine, and a nozzle 4 of metal powder particles is provided above the die mouth 1 of the blown film machine. The metal powder nozzle 4 is a partial mouth, and the partial mouth is provided with a plurality of mouth openings 3 at equal intervals. The multiple mouths 3 are relatively inclined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com