Compound tablet and preparation method thereof

A compound tablet and filler technology, which is applied in pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problems of unsatisfactory tablet appearance, difficult process stability, and tablet stability, etc. problems, to achieve the effect of bright surface, improved appearance and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

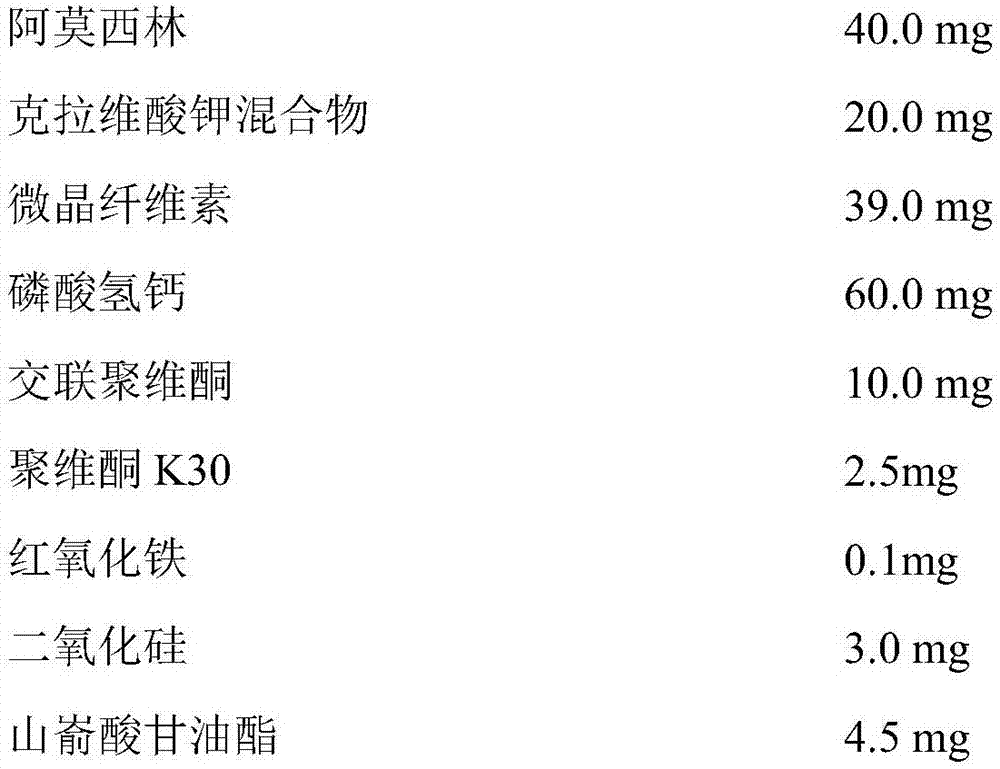

[0029] The quality of each tablet is controlled at 180 ± 13.5mg when the compound recipe amoxicillin and clavulanate potassium tablet of the present embodiment is compressed, and each tablet is formulated according to the following components and dosage:

[0030]

[0031]

[0032] The potassium clavulanate mixture is a mixture of potassium clavulanate and microcrystalline cellulose in a mass ratio of 1:1. Cross-linked povidone, red iron oxide and dehydrated alcohol are formulated into binders and added during tablet preparation, and dehydrated alcohol volatilizes during the tablet preparation process, leaving no residue in the finished tablet.

[0033] The preparation method of the compound recipe amoxicillin-clavulanate potassium tablet of the present embodiment comprises the following concrete steps:

[0034] A. Ingredients: Weigh an appropriate amount of amoxicillin powder, potassium clavulanate mixture, microcrystalline cellulose, calcium hydrogen phosphate, crospovi...

Embodiment 2

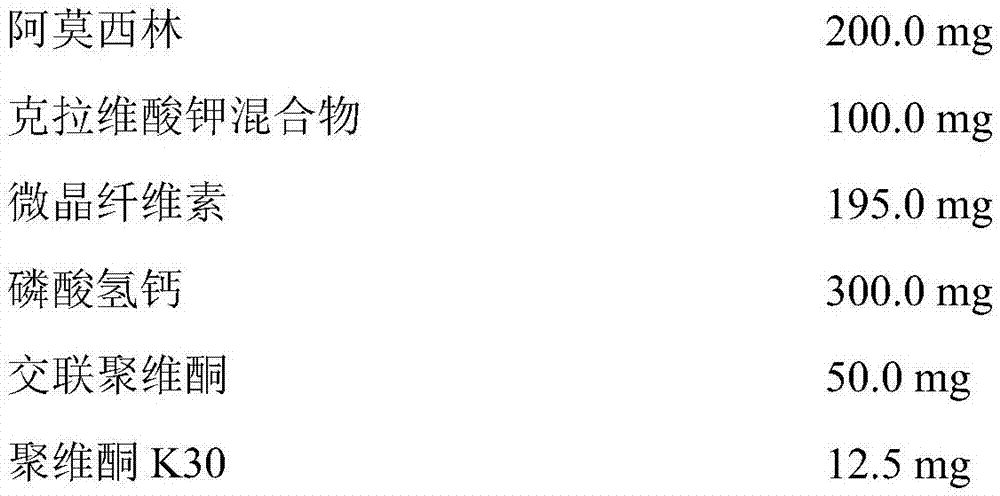

[0041] The remainder of the compound recipe amoxicillin-clavulanate potassium tablet of the present embodiment is identical with embodiment 1, and difference is:

[0042] The quality of each tablet is controlled at 900±45mg during tablet compression, and each tablet is formulated according to the following components and dosage:

[0043]

[0044]

[0045] The rest of the preparation method of the compound amoxicillin-clavulanate potassium tablet of the present embodiment is the same as in Example 1, the difference is that in step B, the prepared amoxicillin powder, microcrystalline cellulose, phosphoric acid Calcium hydrogen and crospovidone were added to the granulator and mixed for 8 minutes. In step C, the prepared amoxicillin granules and the prepared mixture of potassium clavulanate, silicon dioxide, glyceryl behenate and beef flavor essence are added into the three-dimensional motion mixer, and the mixture is discharged after 12 minutes. In step D, the raw materia...

Embodiment 3

[0047] The remainder of the compound recipe amoxicillin-clavulanate potassium tablet of the present embodiment is identical with embodiment 1, and difference is:

[0048] The quality of each tablet is controlled at 1800±36mg during tablet compression, and each tablet is formulated according to the following components and dosage:

[0049]

[0050] The rest of the preparation method of the compound amoxicillin-clavulanate potassium tablet of the present embodiment is the same as in Example 1, the difference is that in step B, the prepared amoxicillin powder, microcrystalline cellulose, phosphoric acid Calcium hydrogen and crospovidone were added to the granulator and mixed for 3 minutes. In step C, the prepared amoxicillin granules and the prepared mixture of potassium clavulanate, silicon dioxide, glyceryl behenate and beef flavor essence are added into a three-dimensional motion mixer, mixed for 8 minutes, and then discharged. In step D, the raw material is compressed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com