Preparation method of fenbendazole microspheres

A technology of fenbendazole microspheres and fenbendazole, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, which can solve the problem of increased coccidiosis outbreaks and few developments. Deworming drugs, high cost of coccidiosis control, etc., to achieve the effect of prolonging the elimination half-life, increasing drug loading, and non-immunogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

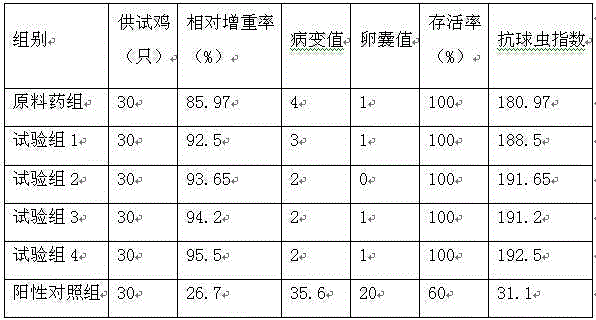

Image

Examples

Embodiment 1

[0010] The preparation method of the fenbendazole microspheres of the present embodiment, make fenbendazole microspheres according to the following steps:

[0011] 1) Take 1g of gelatin, add distilled water to make 5mL gelatin solution, swell completely in a warm water bath at 50°C, and then add 2g

[0012] Fenbendazole, stirred evenly to obtain the water phase;

[0013] 2) Take 24mL of liquid paraffin and 1.0-2.0% Span-80 6mL and mix them to obtain 30mL of oil phase;

[0014] 3) Add the water phase obtained in step 1) to the oil phase obtained in step 2), and stir evenly at a speed of 500 r / min, cool to 5°C, add 2 mL of glutaraldehyde cross-linking agent for cross-linking and solidification , the curing time is 20 minutes;

[0015] 4) Wash off the excess cross-linking agent with isopropanol, then wash off the liquid paraffin on the surface of the microspheres with petroleum ether, and dry in vacuum to obtain fenbendazole microspheres. It was determined that the powder had ...

Embodiment 2

[0017] The preparation method of the fenbendazole microspheres of the present embodiment, make fenbendazole microspheres according to the following steps:

[0018] 1) Take 0.8g of gelatin, add distilled water to make 5mL of gelatin solution, swell completely in a warm water bath at 45°C, then add 1.5g of fenbendazole, stir evenly, and obtain the water phase;

[0019] 2) Take 25mL of liquid paraffin and 5mL of 1.0-2.0% Span-80 and mix them to obtain 30mL of oil phase;

[0020] 3) Add the water phase obtained in step 1) to the oil phase obtained in step 2), and stir evenly at a speed of 600 r / min, cool to 4°C, add 3 mL of glutaraldehyde cross-linking agent for cross-linking and solidification , the curing time is 30 minutes;

[0021] 4) Wash off the excess cross-linking agent with isopropanol, then wash off the liquid paraffin on the surface of the microspheres with petroleum ether, and dry in vacuum to obtain fenbendazole microspheres.

[0022] The microsphere powder with goo...

Embodiment 3

[0024] The preparation method of the fenbendazole microspheres of the present embodiment, make fenbendazole microspheres according to the following steps:

[0025] 1) Take 1.5g of gelatin, add distilled water to make 5mL of gelatin solution, swell completely in a warm water bath at 55°C, then add 1g of fenbendazole, stir evenly, and obtain the water phase;

[0026] 2) Take 30mL of liquid paraffin and 1.0-2.0% Span-80 5mL and mix them to obtain 35mL of oil phase;

[0027] 3) Add the water phase obtained in step 1) to the oil phase obtained in step 2), and stir evenly at a speed of 800 r / min, cool to 3°C, add 4 mL of glutaraldehyde cross-linking agent for cross-linking and solidification , the curing time is 40 minutes;

[0028] 4) Wash off the excess cross-linking agent with isopropanol, then wash off the liquid paraffin on the surface of the microspheres with petroleum ether, and dry in vacuum to obtain fenbendazole microspheres.

[0029] It has good roundness and good dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com