Control method of gas turbine power generation device used for energy storage of natural gas power station super capacitor and gas turbine power generation device

A technology of supercapacitor and gas turbine, which is applied in the direction of gas turbine device, motor generator control, electronic commutation motor control, etc., and can solve problems such as unstable operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

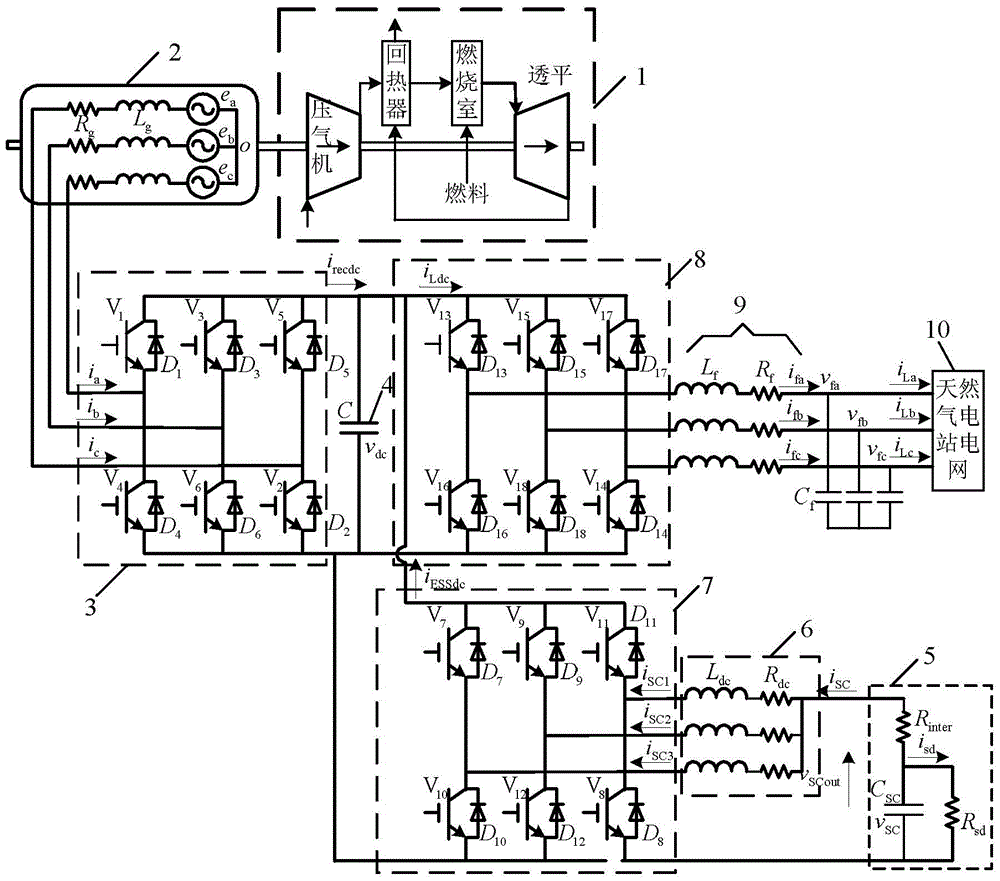

[0065] Specific implementation mode 1, refer to image 3 and Figure 4 This embodiment is specifically described. The control method of the gas turbine power generation device used for supercapacitor energy storage in natural gas power plants described in this embodiment is realized based on the gas turbine power generation device. The gas turbine power generation device includes a micro gas turbine 1, a permanent magnet synchronous Generator 2, PWM rectification switch module 3, DC filter capacitor 4, super capacitor 5, DC conversion switch module 7, inverter switch module 8 and natural gas power station grid 10;

[0066] The micro gas turbine 1 is coaxially connected with the permanent magnet synchronous generator 2, the stator three-phase line of the permanent magnet synchronous generator 2 is connected with the three-phase line of the AC side of the PWM rectifier switch module 3, and the bus bar of the DC side of the PWM rectifier switch module 3 A DC filter capacitor 4 i...

specific Embodiment approach 2

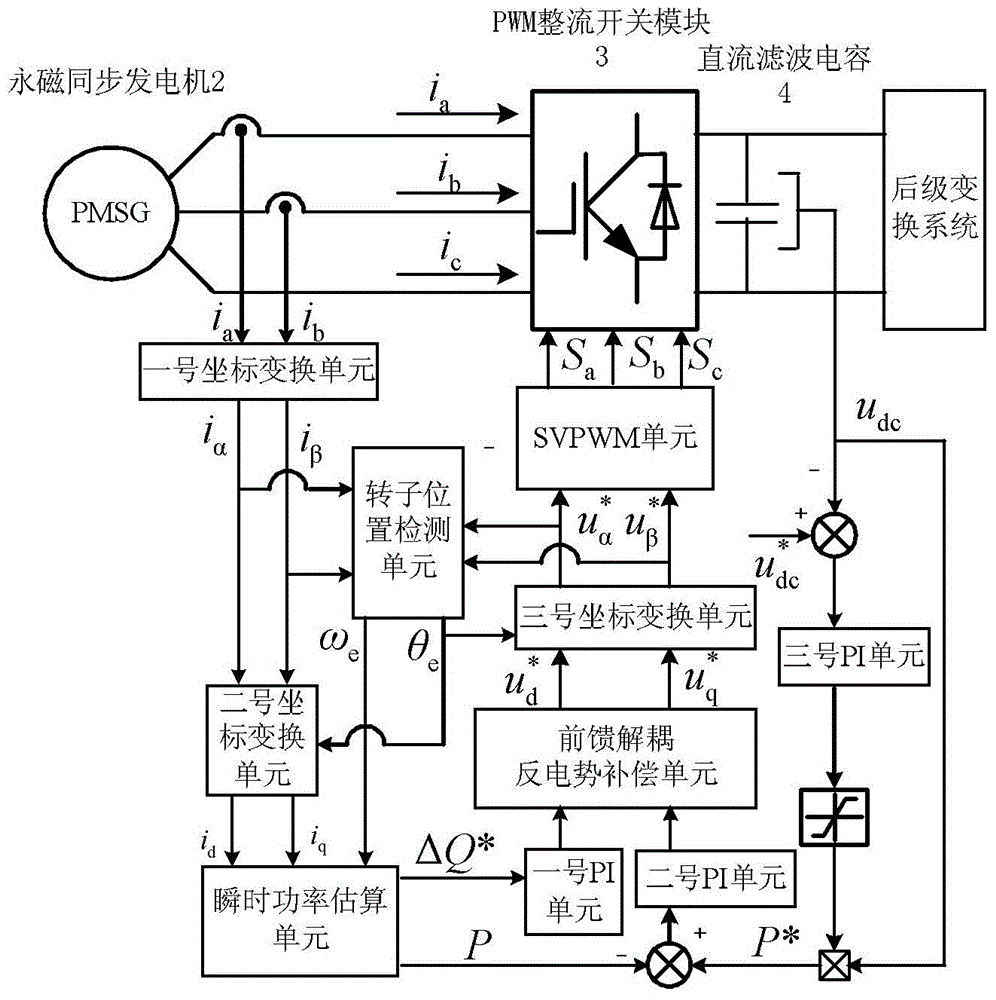

[0078] Specific implementation mode two, refer to image 3 Describe this embodiment. This embodiment is a further description of the control method of the gas turbine power generation device used for supercapacitor energy storage in natural gas power plants described in Embodiment 1. In this embodiment, the PWM rectification described in the start control method The switch module 3 converts the DC bus voltage into an AC bus voltage to drive the permanent magnet synchronous generator 2 to rotate and speed up, and the method for the PWM rectification switch module 3 to drive the permanent magnet synchronous generator 2 to rotate is as follows:

[0079] Stator current i a i b The stator current i in the two-phase static coordinate system is obtained after the No. 1 coordinate transformation unit α i β And output to the No. 2 coordinate transformation unit; output the stator current i under the two-phase synchronous rotating coordinate system after passing through the No. 2 coo...

specific Embodiment approach 3

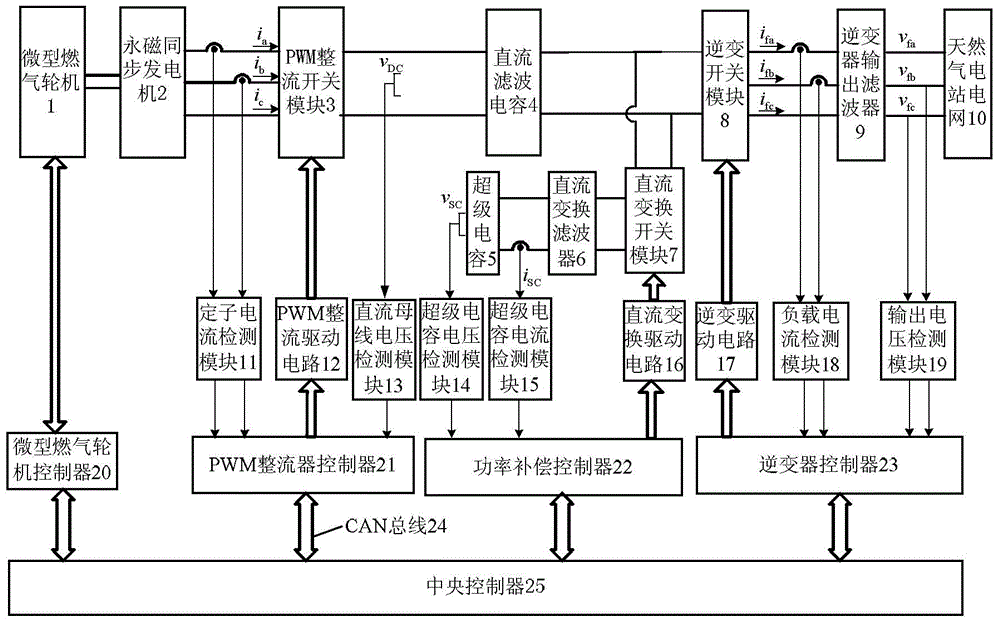

[0089] Specific implementation mode three, refer to figure 1 and figure 2 Describe this embodiment in detail, the gas turbine power generation device used for supercapacitor energy storage in natural gas power plants described in this embodiment includes power generation components and control power generation components; the power generation components include micro gas turbines 1, permanent magnet synchronous generators 2, PWM rectifiers Switch module 3, DC filter capacitor 4, super capacitor 5, DC conversion switch module 7, inverter switch module 8, inverter output filter 9 and natural gas power station grid 10; control power generation components include stator current detection module 11, PWM rectifier Drive circuit 12, DC bus voltage detection module 13, super capacitor voltage detection module 14, super capacitor current detection module 15, DC conversion drive circuit 16, inverter drive circuit 17, load current detection module 18, output voltage detection module 19,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com