Novel ammonia sensor and preparation technology thereof

An ammonia gas sensor and a preparation process technology, which are applied in the field of sensors, can solve problems such as poor ammonia gas selectivity of gas-sensitive thin films, and achieve the effects of improving electron transmission performance, high gas-sensing performance, and increasing effective contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

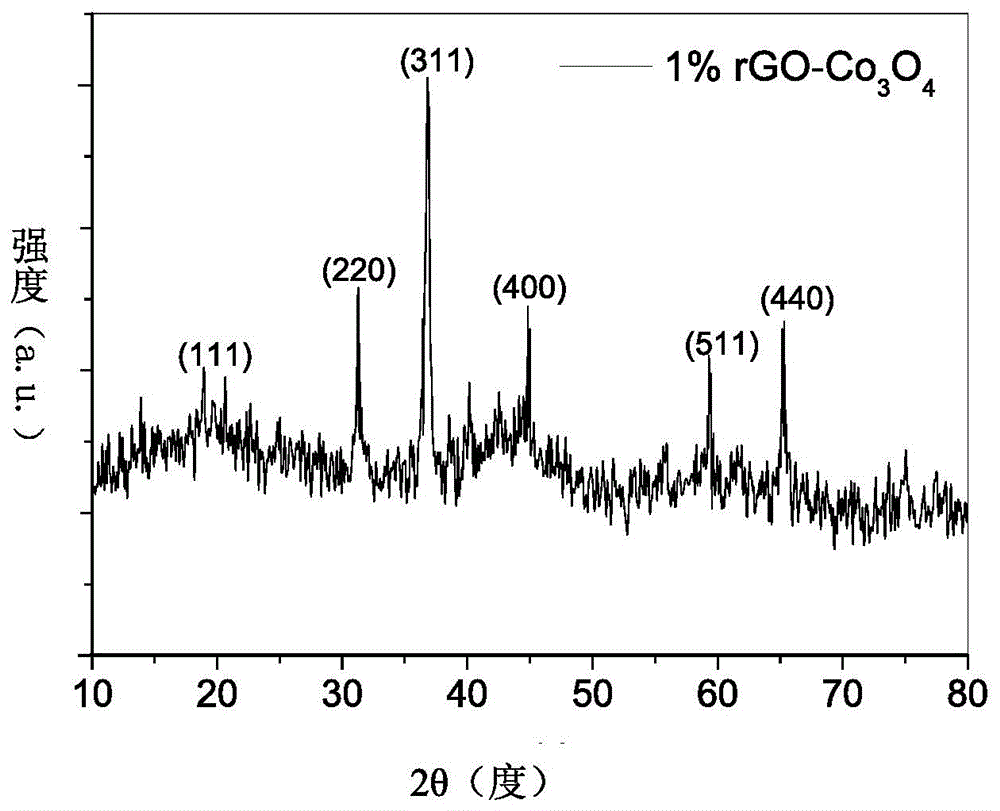

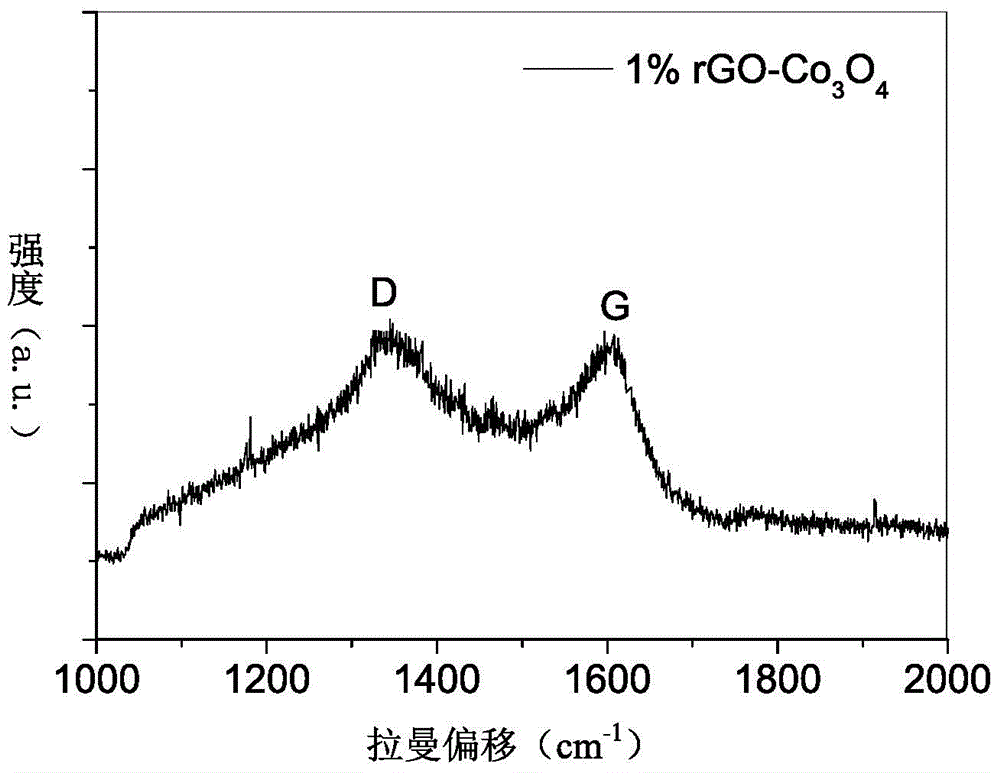

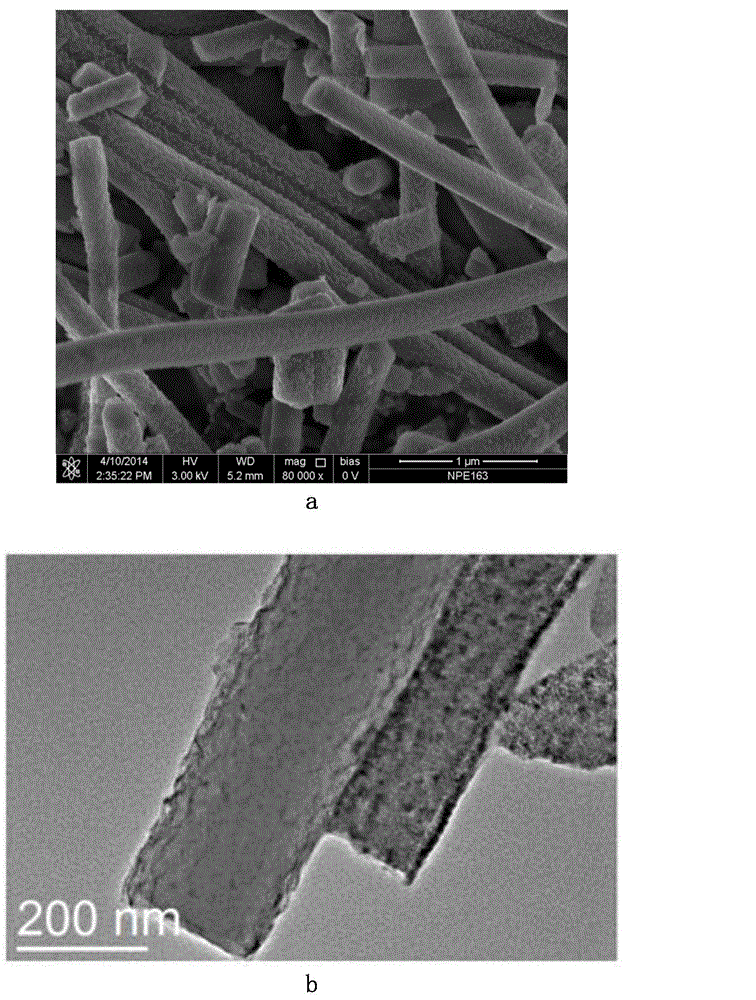

Embodiment 1

[0044] A new type of ammonia gas sensor, including a gas-sensitive material and a substrate. The gas-sensitive material is evenly coated on the surface of the substrate. The coating thickness of the gas-sensitive material is 100μm. The composition of the gas-sensitive material includes reducing graphene wrapped cobalt tetroxide composite nanofibers. The graphene-coated cobalt tetroxide composite nanofibers include reduced graphene and cobalt tetroxide. The reduced graphene is wrapped on cobalt tetroxide. The mass fraction of the composite nanofibers is 1%. The average diameter of the composite nanofibers is 1%. It is 200nm, the average diameter of Co3O4 is 20nm, the preparation method includes the following steps:

[0045] Step 1, preparing a graphene oxide dispersion: disperse 0.02 parts by mass of graphene oxide into 0.06 parts by mass of dimethylformamide, and ultrasonicate in a 250W ultrasonic machine for 4 hours to obtain a graphene oxide dispersion;

[0046] Step two, prepare...

Embodiment 2

[0052] A new type of ammonia gas sensor, including a gas-sensitive material and a substrate. The gas-sensitive material is uniformly coated on the surface of the substrate. The coating thickness of the gas-sensitive material is 1μm. The composition of the gas-sensitive material includes reducing graphene wrapped cobalt tetroxide composite nanofibers. The graphene-coated cobalt tetroxide composite nanofibers include reduced graphene and cobalt tetroxide. The reduced graphene is wrapped on cobalt tetroxide. The mass fraction of the composite nanofibers is 6%. The average diameter of the composite nanofibers is 6%. It is 250nm, the average diameter of Co3O4 is 30nm, and the preparation method includes the following steps:

[0053] Step one: preparing a graphene oxide dispersion: disperse 0.05 parts by mass of graphene oxide into 2 parts by mass of dimethylformamide, and sonicate it in a 250W ultrasonic machine for 2 hours to obtain a graphene oxide dispersion;

[0054] Step two, prepa...

Embodiment 3

[0059] A new type of ammonia gas sensor, including a gas-sensitive material and a substrate. The gas-sensitive material is uniformly coated on the surface of the substrate. The coating thickness of the gas-sensitive material is 50μm. The composition of the gas-sensitive material includes reducing graphene wrapped cobalt tetroxide composite nanofibers. The graphene-coated cobalt tetroxide composite nanofibers include reduced graphene and cobalt tetroxide. The reduced graphene is wrapped on cobalt tetroxide. The reduced graphene accounts for 10% of the composite nanofibers. The average diameter of the reduced graphene-coated cobalt tetroxide composite nanofibers It is 300nm, the average diameter of Co3O4 is 40nm, the preparation method includes the following steps:

[0060] Step one: preparing a graphene oxide dispersion: disperse 1.6 parts by mass of graphene oxide into 8 parts by mass of dimethylformamide, and ultrasonicate in a 250W ultrasonic machine for 5 hours to obtain a grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com