Control method of regenerative combustion equipment

A technology of combustion equipment and control method, which is applied to combustion methods, combustion equipment, lighting and heating equipment, etc., can solve the problems of flue gas temperature affecting the safe operation of environmental protection devices, large furnace pressure fluctuations, and long commutation time. There is a large excess of combustion-supporting gas, the furnace pressure is stable, and the effect of avoiding explosion and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

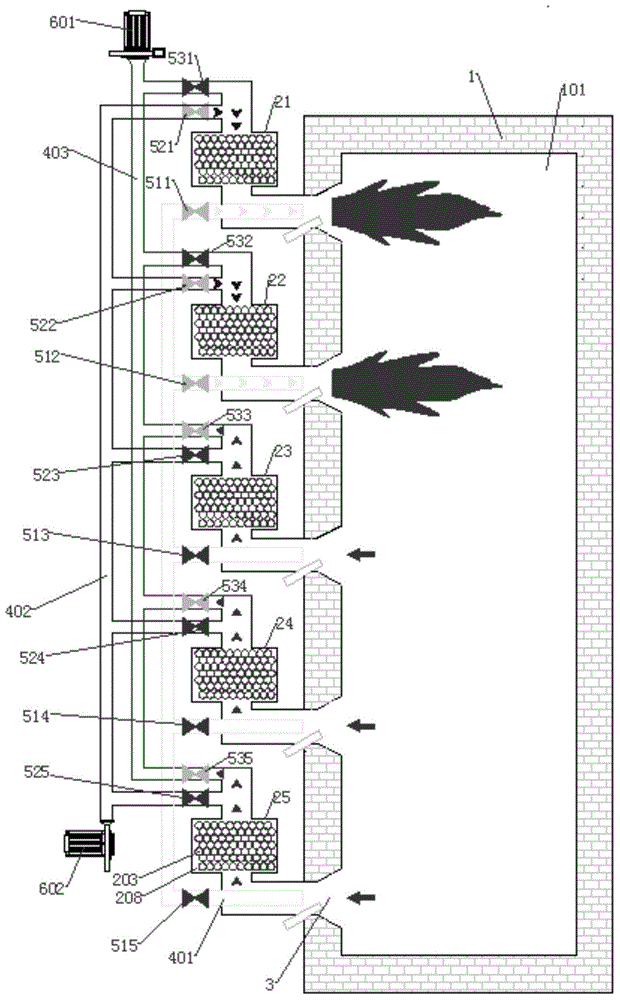

[0064] The control method of the regenerative combustion equipment provided by the present invention includes an ignition step, a start-up step, a combustion step, a switching step and a circulation step, such as image 3 shown. A control method of the regenerative combustion equipment of the present invention and its various steps will be described in detail below.

[0065] In one embodiment, the regenerative combustion equipment includes five regenerative burners arranged in sequence, that is, the first regenerative burner 21, the second regenerative burner 22, the third regenerative burner 23. The fourth regenerative burner 24 and the fifth regenerative burner 25, two of which are used for combustion and three for smoke exhaust. Set the working time of each regenerative burner for combustion to 60s, then the switching interval is 60s / 2=30s.

[0066] The ignition step involves first firing a regenerative burner, such as figure 2 shown. In this embodiment, the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com