Bendable LED aluminum substrate light source and manufacturing method thereof

A technology of LED aluminum substrate and manufacturing method, which is applied in the field of LED light sources, and can solve problems such as heavy workload, many solder joints, and difficulty in ensuring soldering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

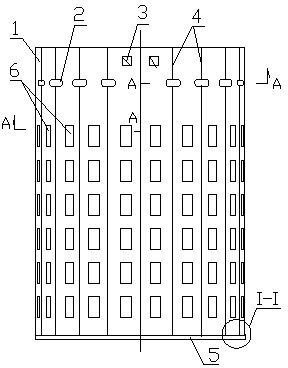

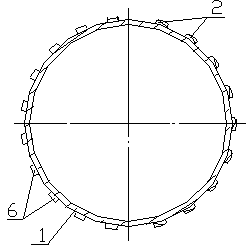

[0025] Such as Figure 1-Figure 9 As shown, the following is an embodiment of LED 360-degree light-emitting energy-saving lamps:

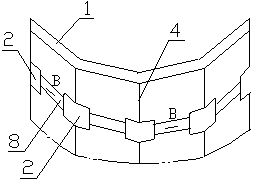

[0026] The bendable LED aluminum substrate light source includes an aluminum substrate 1 that is cylindrical after bending or a three-dimensional shape that needs to be bent (such as an approximate cylindrical shape, a prism) and a lamp bead 6 arranged on the aluminum substrate. According to the number of sides of the cylindrical aluminum substrate, before the aluminum substrate is bent, between the same long strips that make up the cylinder, along the mutual bending axis of every two long strips of the aluminum substrate, set a V cut on the aluminum alloy surface of the aluminum substrate. Line 4, a circuit board 8 is provided on the copper-clad surface of the aluminum substrate through the PCB manufacturing process, and a crossing pad 7 is provided through the PCB manufacturing process at the corresponding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com