Mortar spreading bucket and mortar spreading method using same

A technology of ash spreading and bucket storage, which is applied in construction, building structure, and building material processing, etc. It can solve the problems of difficulty in quality assurance, difficulty in control, and low efficiency of ash spreading, so as to ensure construction quality and improve construction efficiency , to overcome the effect of poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

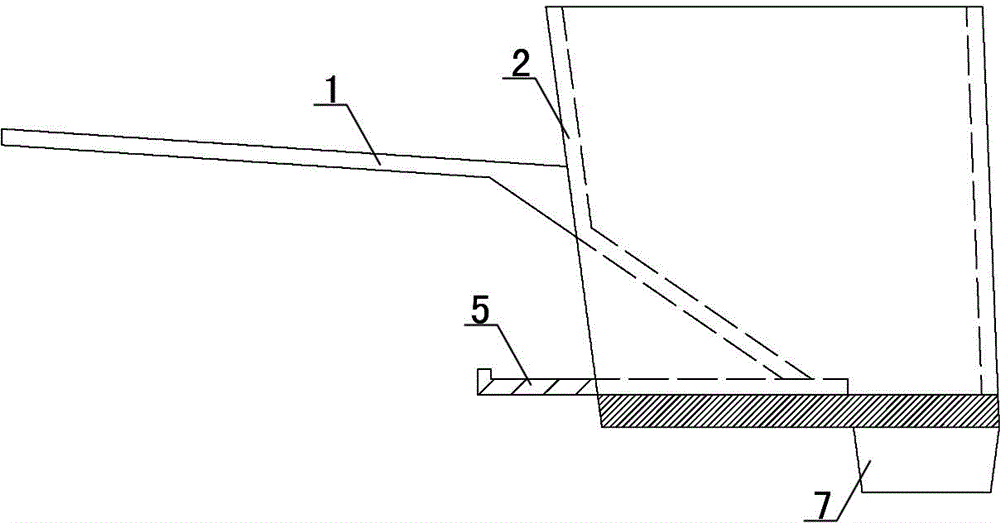

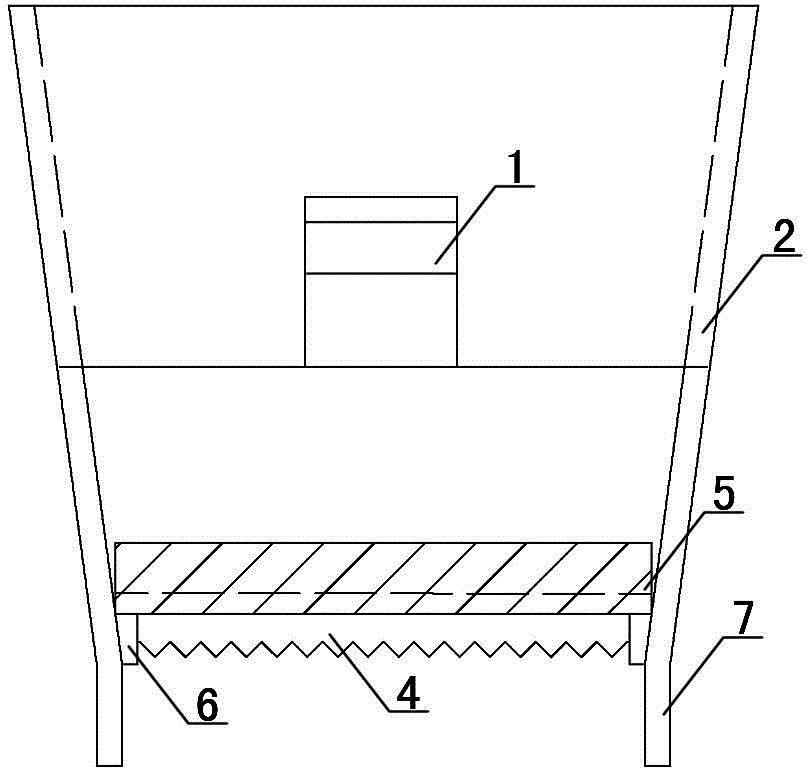

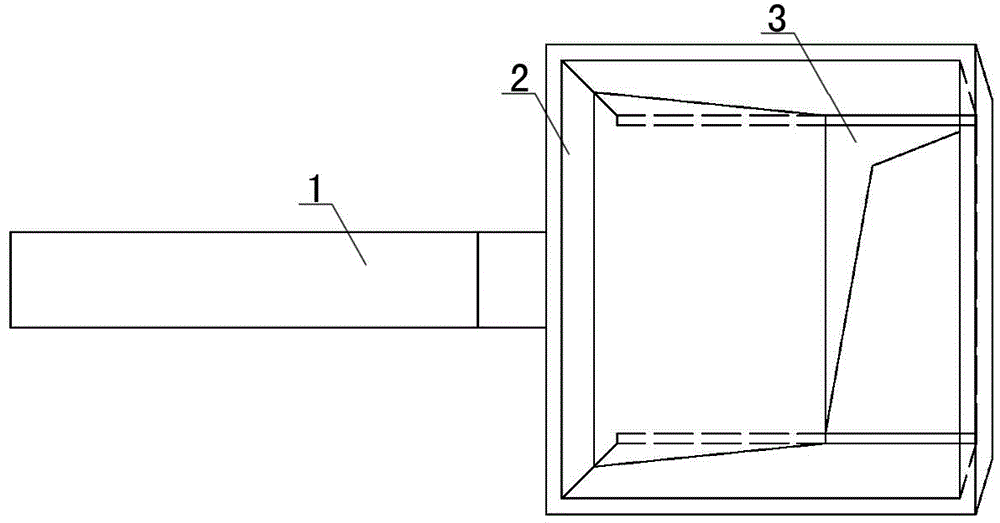

[0028] Examples see figure 1 As shown, this ash bucket includes a bucket 2 and a handle 1 connected to the bucket. The bucket 2 is surrounded by a front panel, a rear panel and two side panels. The handle 1 is connected to the 2 on the rear panel, see image 3 As shown, the lower half of the rear plate of the hopper 2 is an inclined plane inclined to the front plate, and forms an ash outlet 3 between the front plate, see figure 2 As shown, the bottom of the ash outlet 3 of the hopper 2 is slidably connected with a movable bottom plate 5, and the inner sides of the two side plates of the hopper 2 are respectively connected with a limit bar 6, and the movable bottom plate 5 is slidably connected along the limit bar 6, The side boards of the bucket bin 2 each extend downwards with a side board 7 at the position of the ash outlet, and a scraper 4 with a sawtooth edge is connected between the two side boards 7 below the front board of the bucket bin 2 .

[0029] The height diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com