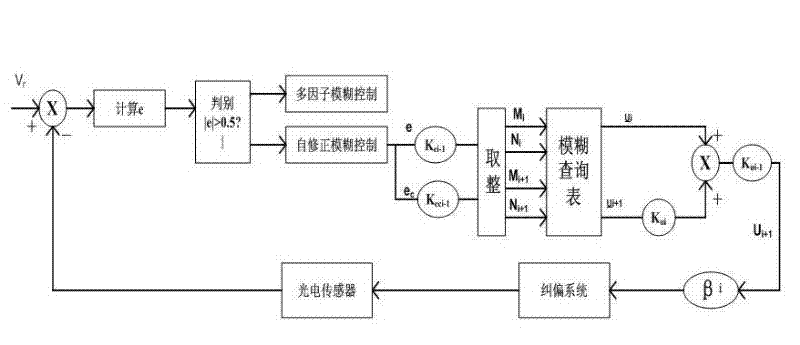

Micro-deviation area self-correction fuzzy control method

A technology of fuzzy control and deviation area, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of easy correction too large, inability to quickly correct, weak micro-deviation control, etc., to achieve fast correction speed, The operation speed is fast and the effect of overcoming the poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

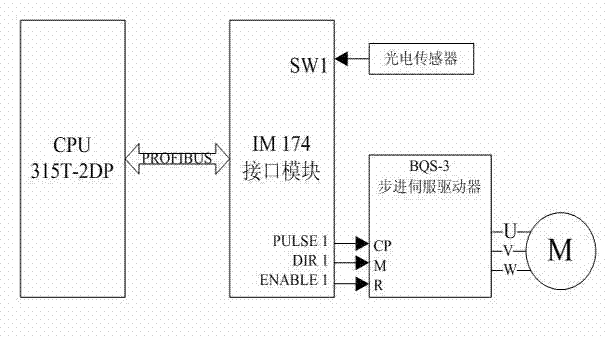

[0010] Such as figure 1 As shown, a set of high-precision deviation correction control system is constructed first, and the photoelectric sensor and stepping servo driver in the existing coil material deviation guiding control device are respectively connected to the CPU through the same interface module. The stepping servo driver adopts the model BQS -3 drivers, the stepper servo driver is connected to the stepper motor, and then connected to the CPU through the interface module. The interface module adopts the model IM174 interface module. The photoelectric sensor is connected through the analog terminal SW1 of the drive interface of the interface module, and the CP terminal of the stepper servo driver is the pulse signal terminal for receiving the interface module, and controls the movement of the stepper motor according to the frequency and number of received pulses. The M terminal of the driver receives the signal from the interface module to control the steering of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com