Flexible stone production line conveying net belt jaw wheel rectifying device

A technology of deviation correction device and transmission network, which is applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., and can solve problems such as large space occupied by deviation correction device, slow deviation correction speed of guide roller, shortened service life of cylinder drive device, etc. Achieve the effect of small space occupation and fast correction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

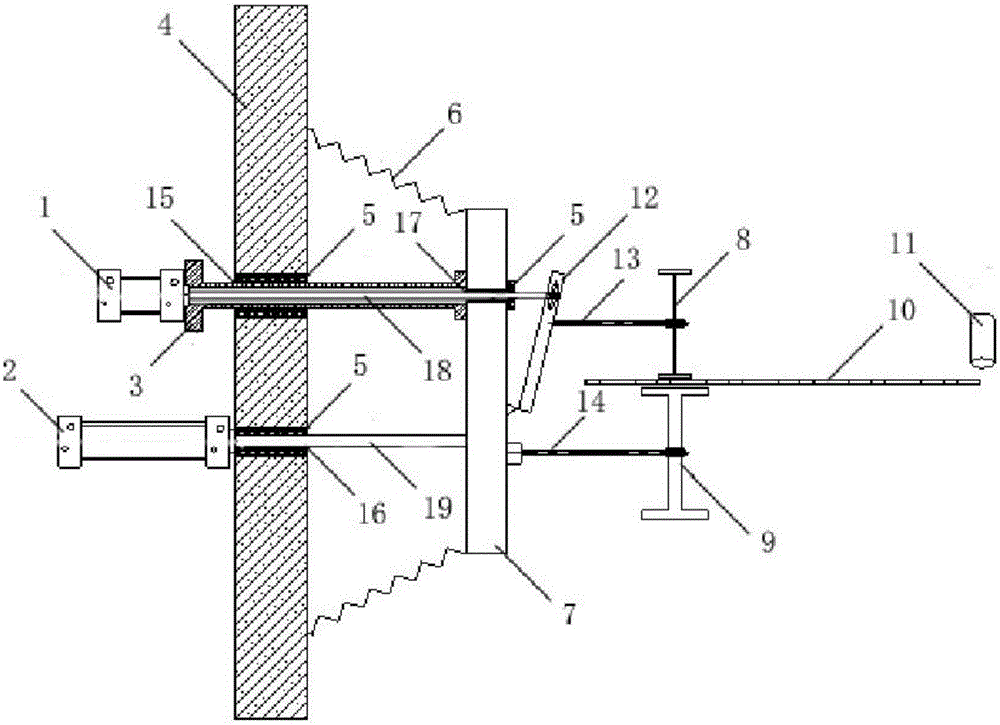

[0015] Such as figure 1 As shown, a flexible stone production line transmission network belt claw wheel deviation correction device includes a position sensor 11 installed on one side of the transmission network belt 10, a deviation correction controller for receiving signals from the position sensor 11, and a push-pull device controlled by the deviation correction controller. Mechanism, claw wheel clamping mechanism;

[0016] The push-pull mechanism includes a push-pull cylinder 2 arranged on the outside of the side wall 4 of the drying tunnel, a sliding bottom plate 7 arranged vertically on the inside of the side wall 4 of the drying tunnel, and one end connected to the push-pull cylinder 2 and the other end connected to the sliding bottom plate The bottom plate push rod 19 arranged horizontally on the outside of 7; the side wall 4 of the drying tunnel is provided with a second channel 16 for the bottom plate push rod 19 to pass through; fixed wheel 9 on the lower side;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com