Desizing pretreatment method of textile

A textile and desizing technology, applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve problems such as high consumption, resource protection and ecological environment threats, achieve mild reaction, improve desizing efficiency, equipment and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

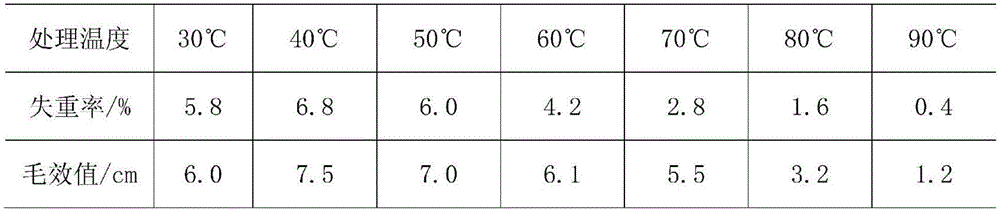

Examples

Embodiment 1

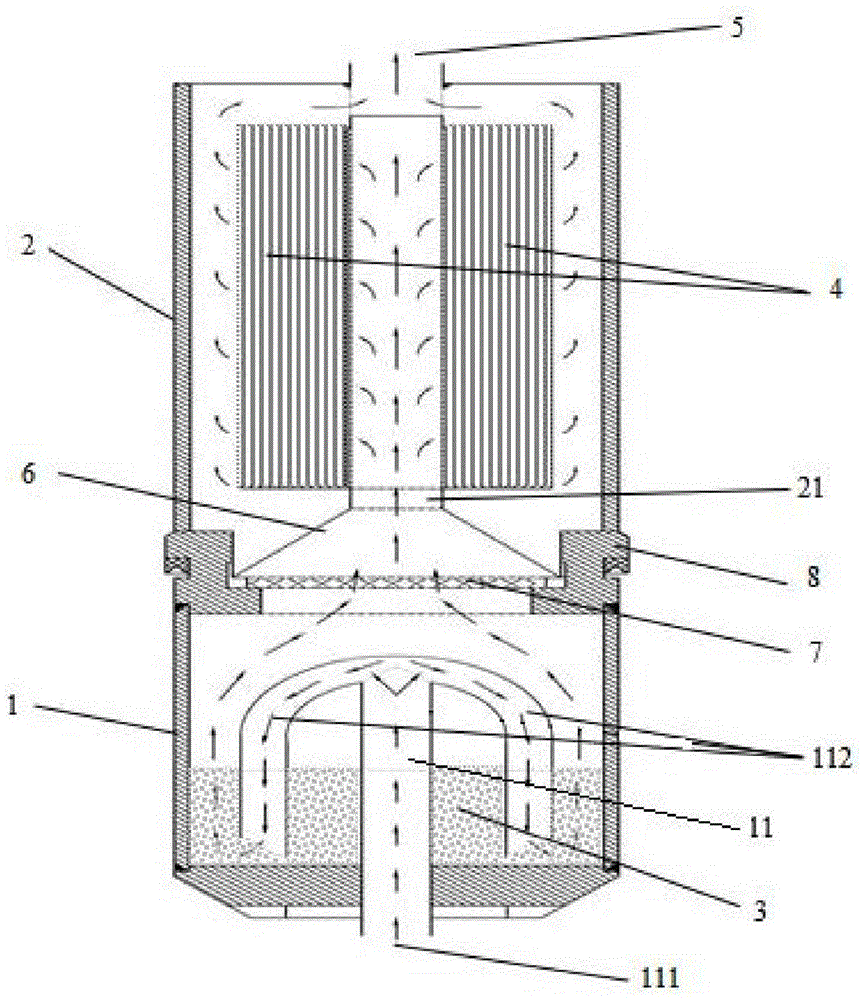

[0025] The invention provides a pretreatment method for desizing of textiles, the enzymatic desizing pretreatment method adopts such as figure 1 The supercritical carbon dioxide fluid desizing device of the shown structure is realized. The desizing device includes a desizing liquid storage tank 1 and a desizing tank 2 sealedly connected with the desizing liquid storage tank 1 through a connecting device 8 .

[0026] The desizing liquid storage tank 1 is a cylindrical tank body, and an inverted "mountain" type tubular fluid distributor 11 is installed inside the desizing liquid storage tank 1, which is mainly composed of three interconnected pipes, and the central pipe is a circulating fluid Inlet pipe 111, the bottom end of circulating fluid inlet pipe 111 is connected with the supercritical carbon dioxide fluid treatment system (not shown in the figure) with circulation pump; Two pipelines positioned at both sides are circulating fluid outlet pipe 112, two circulations The n...

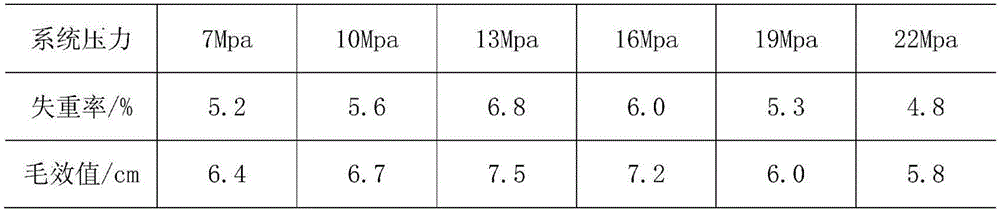

Embodiment 2

[0044] The present invention provides a textile desizing pretreatment method, the enzymatic desizing pretreatment method is basically the same as the desizing pretreatment method described in Example 1, and will not be repeated here.

[0045] The differences are: the reaction temperature in this embodiment is 50° C., the pressure is 13 MPa, and the total time for desizing treatment is 1 h.

[0046] The test results of the weight loss rate and gross effect value of the desized textiles in this embodiment are: the weight loss rate is 6.0%, and the gross effect value is 7.0 em.

Embodiment 3

[0048] The present invention provides a textile desizing pretreatment method, the enzymatic desizing pretreatment method is basically the same as the desizing pretreatment method described in Example 1, and will not be repeated here.

[0049] The differences are: the reaction temperature in this embodiment is 60° C., the pressure is 13 MPa, and the total time for desizing treatment is 1 h.

[0050] The test results of the weight loss rate and gross effect value of the desized textiles in this embodiment are: the weight loss rate is 4.2%, and the gross effect value is 6.1 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com