Method for weaving fabrics with high moisture absorption and free styles

A high-hygroscopicity and fabric technology, applied in the field of fabric weaving and high-hygroscopicity fabrics, can solve the problems of high price and surface style restrictions, and achieve the effect of increasing the fluffy performance, avoiding many fabric defects, and increasing the surface effect of the fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

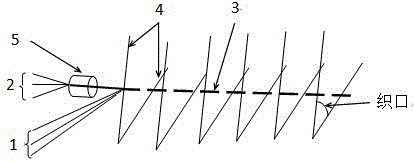

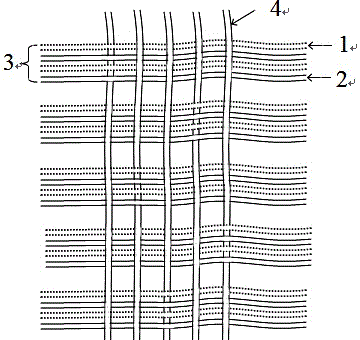

[0032] Weaving of moisture-absorbing fabrics with free style: the warp yarn [4] is made of 80S compact spun pure cotton yarn, the weft yarn [3] contains 2 heavy mesh 25D polyester filaments [2] and 2 60S pure cotton yarns [1], and the gray cloth is put on the machine The warp density is 190 threads / inch, the weft density is 52*4 threads / inch, and the fabric structure is 5 pieces of 3 flying warp satin. The schematic diagram of the structure is as follows figure 2 , before weaving, the four yarns in the weft yarn [3] are respectively distributed on the four bobbins. After the silk [2] passes through the spraying device [5], it is introduced into the weaving mouth simultaneously with the two cellulose fiber yarns [1] through the air-jet loom; The water-dispersible polyester (Dongguan Guchuan Textile Auxiliary Co., Ltd.), the pH of the spray liquid and the water used for the water-jet loom is between 5-7, and the warp [4] is sized before weaving. The slurry is a mixed slurry co...

Embodiment 2

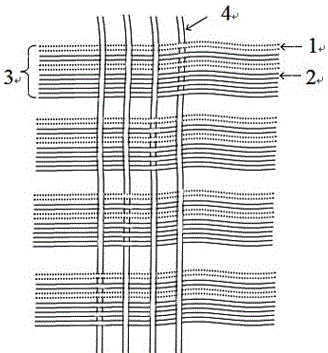

[0052] This embodiment provides a method for manufacturing a highly hygroscopic fabric. The warp yarn [4] is 80S compact spun pure cotton yarn, and the weft yarn [3] contains 4 25D polyester filaments [2] and 2 80S tencel yarns [1]. The warp density on the gray cloth is 190 threads / inch, the weft density is 50*6 threads / inch, and the fabric structure is 3 / 1 twill. The schematic diagram of the structure is shown in image 3 . Before weaving, the four yarns in the weft yarn [3] are respectively distributed on 6 bobbins. When weaving, the four yarns in the weft yarn [3] are wound on 6 weft feeders, and then 4 polyester filaments [2] After passing through the spraying device [5], the two cellulose fiber yarns [1] are introduced into the loom at the same time through the air-jet loom, and the spray liquid for spraying polyester filaments [2] has a concentration of 0.9g / l Water-dispersible polyester (Dongguan Guchuan Textile Auxiliary Co., Ltd.), the pH of the spray liquid and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com