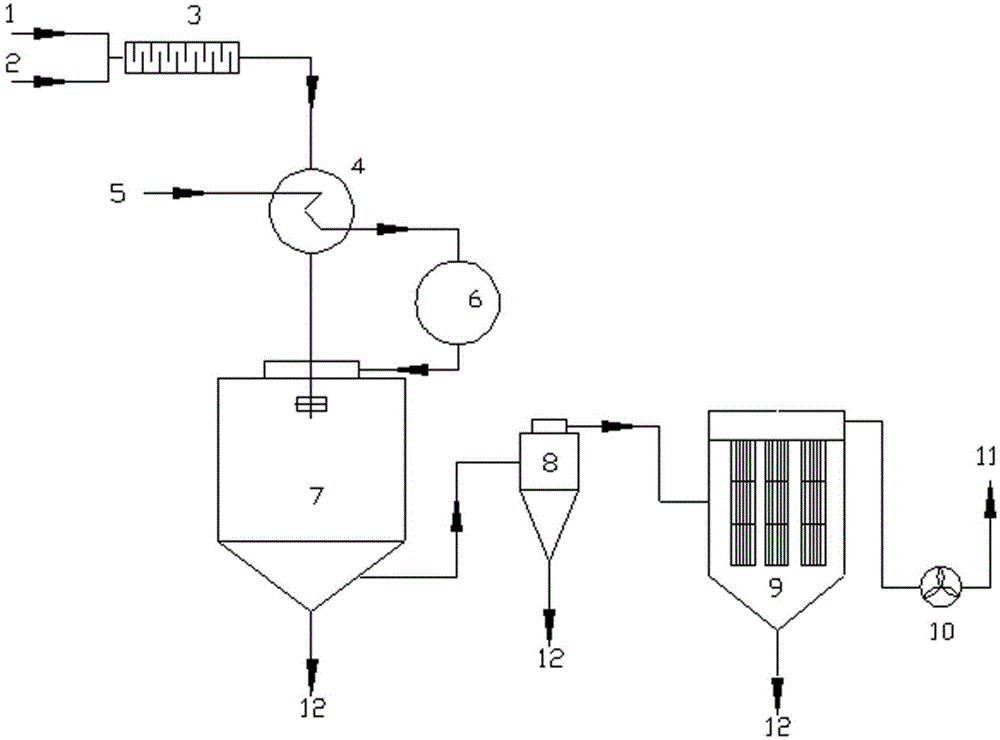

Production process and production device for preparing industrial additives from electrostatic acid and application thereof

A production process, electrostatic acid technology, applied in applications, other household appliances, ceramic products, etc., can solve the problems of ineffective use of neutralization heat, low production efficiency, and large neutralization heat release, and achieve neutralization. The effect of stable and controllable heat release, simple installation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] AEO the organic material 2 (Fatty alcohol polyoxyethylene ether) and the electrostatic acid and 32% liquid caustic produced during the sulfonation of sulfur trioxide enter the static mixer at the same time. The weight ratio of the electrostatic acid to the liquid caustic is 1:1.5. Fully mix and neutralize in the medium (the temperature after neutralization is 110°C), enter the heat exchanger to exchange heat with dry air, then cool down to 60°C, and then enter the spray dryer. At the same time, the dry air heats up to 90°C through a heat exchanger, then heats up to 140°C through an air heater and enters the spray dryer. After the mixed material is atomized into mist droplets, it is contacted with the hot air in the downstream direction to finally obtain a granular industrial additive with a solid content of 95.3%, an active substance of 21%, a pH of 8.3, and a particle size D85 of 510 μm.

[0036] The granular product can be directly used as a metal cleaning agent, app...

Embodiment 2

[0038] The electrostatic acid and 32% liquid caustic produced during the sulfonation of organic materials α-olefin and sulfur trioxide enter the static mixer at the same time. The weight ratio of the electrostatic acid to the liquid caustic is 1:1.5. Mix and neutralize (the temperature after neutralization is 110°C), enter the heat exchanger to exchange heat with dry air, then cool down to 60°C, and then enter the rotary spray dryer. At the same time, the dry air heats up to 85°C through the heat exchanger, and then heats up to 130°C through an air heater and enters the rotary spray dryer. After the mixed material is atomized into mist droplets, it is contacted with the hot air in the downstream direction to finally obtain a granular industrial additive with a solid content of 94.8%, an active substance of 32%, a pH of 9.3, and a particle size D85 of 545 μm.

[0039]After the granular product is compounded with sodium metasilicate at a mass ratio of 2:1 (stirred and mixed acco...

Embodiment 3

[0041] The electrostatic acid and 40% liquid caustic produced during the sulfonation of fatty acid methyl ester and sulfur trioxide enter the static mixer at the same time. The weight ratio of the electrostatic acid and liquid caustic is 1:1.2, and the two are fully mixed in the static mixer and (the temperature after neutralization is 115°C), enter the heat exchanger to exchange heat with dry air, then cool down to 60°C, and then enter the spray dryer. At the same time, the dry air heats up to 90°C through a heat exchanger, then heats up to 140°C through an air heater and enters the spray dryer. After the mixed material is atomized into mist droplets, it is contacted with the hot air in the downstream direction to finally obtain a granular industrial additive with a solid content of 96.3%, an active substance of 26%, a pH of 6.3, and a particle size D85 of 490 μm.

[0042] After the granular product is compounded with soda ash at a mass ratio of 3:1, a metal cleaning agent wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com