Preparation method of RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer

A technology of surface modification layer and mirror, applied in coating, sputtering, metal material coating process, etc., can solve the problem of difficult to grow uniform and dense Si modified layer, and improve polishing characteristics, film quality and so on. The effect of uniform and high film density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a surface modification layer of an RB-SiC substrate mirror, comprising the following steps:

[0025] Step 1. Preparation of coating conditions: install the Si target on the twin sputtering cathodes of the coating machine, clean the surface of the RB-SiC substrate, fix it on the workpiece fixture of the coating machine, vacuum the coating machine, and apply a vacuum to the RB-SiC The base is baked;

[0026] Step 2, sputtering cathode Si target surface treatment: the sputtering cathode is fed with Ar gas, and the power of the intermediate frequency power supply is adjusted to perform pre-sputtering treatment on the surface of the Si target;

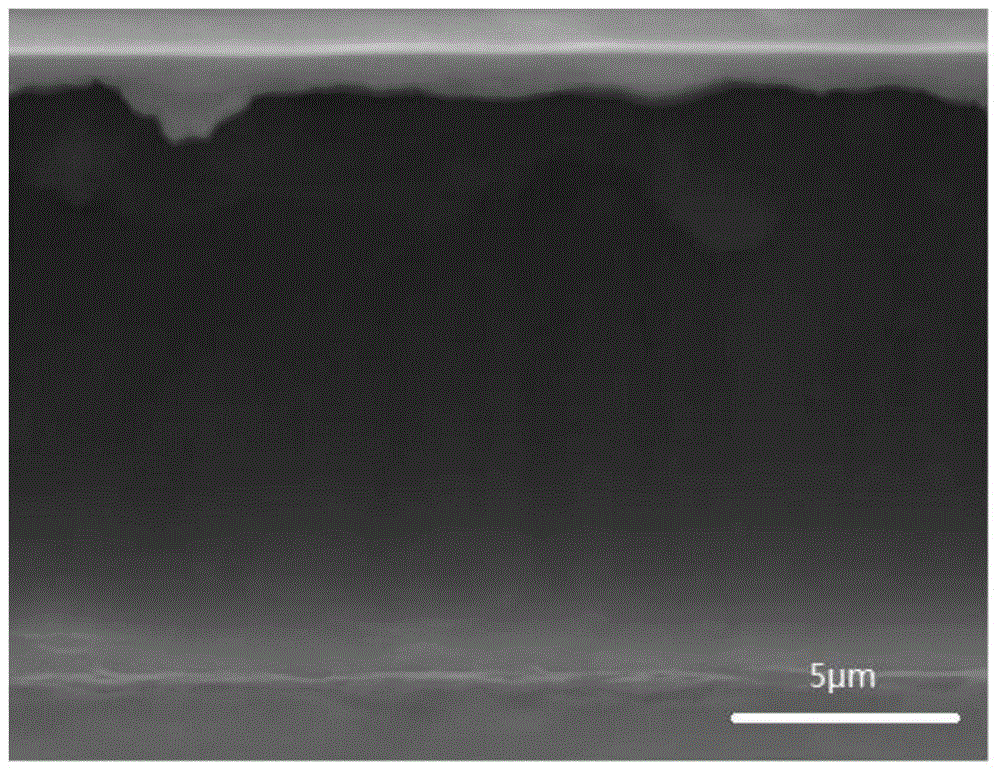

[0027] Step 3, preparing the Si modified layer: increasing the power of the intermediate frequency power supply and the flow rate of Ar gas, and depositing the Si modified layer on the RB-SiC substrate by using the intermediate frequency magnetron sputtering technology.

[0028] The inve...

Embodiment 1

[0036] The preparation method of the modified layer of the RB-SiC base reflector comprises the following specific steps:

[0037] Step 1. Preparation of coating conditions: install the Si target on the twin sputtering cathodes of the coating machine, clean the surface of the RB-SiC substrate, fix it on the workpiece fixture of the coating machine, and evacuate the vacuum chamber of the coating machine to 4.5 ×10 -4 Pa, bake at a temperature of 200°C and keep the temperature constant for 90 minutes;

[0038]Step 2. Sputtering cathode Si target surface treatment: pass high-purity Ar into the sputtering cathode, adjust the Ar flow rate to 400 sccm, adjust the power of the intermediate frequency power supply to 3KW, and the sputtering time to 50 minutes to make the high-energy Ar + Ions bombard the target surface;

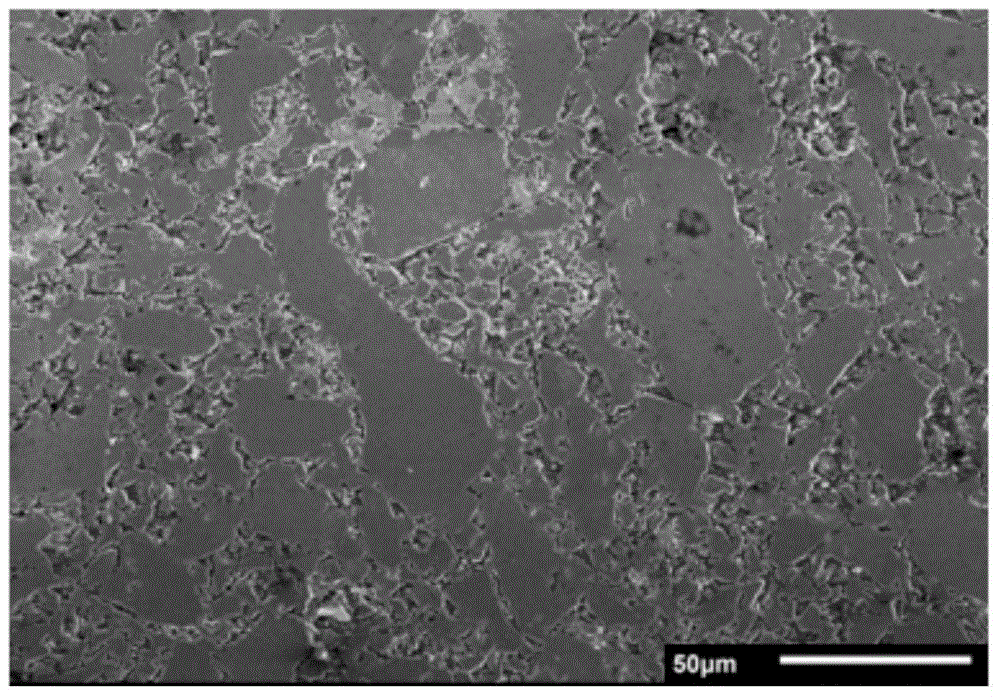

[0039] Step 3, preparing the Si modified layer: adjust the power of the intermediate frequency power supply to 15KW, adjust the Ar gas flow to 550 sccm, and grow the...

Embodiment 2

[0043] The preparation method of the modified layer of the RB-SiC base reflector comprises the following specific steps:

[0044] Step 1. Preparation of coating conditions: install the Si target on the twin sputtering cathodes of the coating machine, clean the surface of the RB-SiC substrate, fix it on the workpiece fixture of the coating machine, and evacuate the vacuum chamber of the coating machine to 5.0 ×10 -4 Pa, bake at a temperature of 180°C and keep the temperature constant for 60 minutes;

[0045] Step 2. Sputtering cathode Si target surface treatment: pass high-purity Ar into the sputtering cathode, adjust the Ar flow rate to 350 sccm, adjust the intermediate frequency power supply to 2KW, and the sputtering time to 40 minutes to make the high-energy Ar + Ions bombard the target surface;

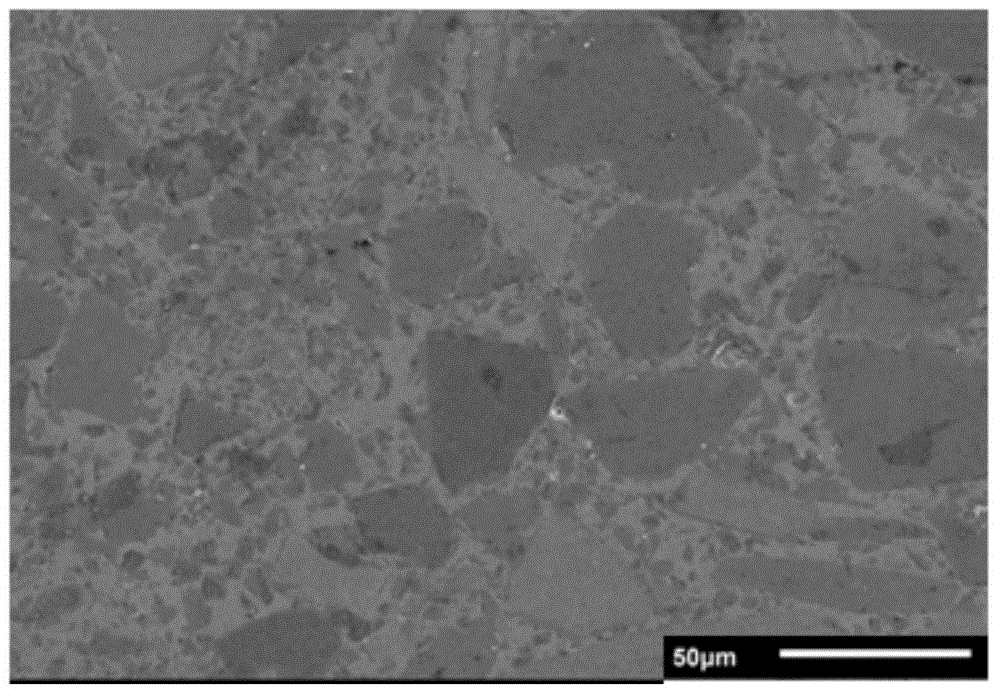

[0046] Step 3. Prepare the Si modified layer: adjust the power of the intermediate frequency power supply to 12KW, adjust the Ar gas flow to 500 sccm, and grow the Si modified l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com