Technology for producing spheroidal graphite cast iron

A production process and technology of ductile iron, which is applied in the field of production technology of -40 ℃ low temperature impact ductile iron, and achieves the effects of high performance strength, advanced technology and good low temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

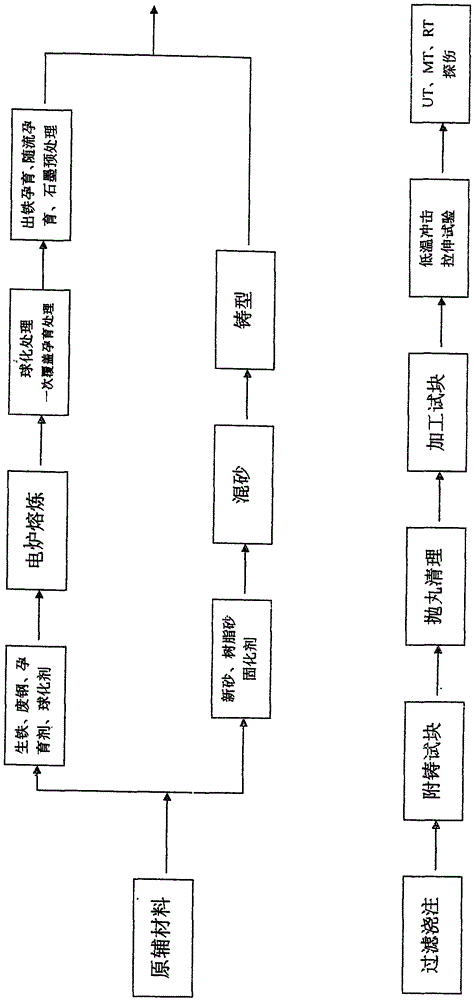

[0021] As shown in the figure, the process flow is:

[0022] (1) Selection of raw and auxiliary materials

[0023] In order to meet the requirements of low-temperature impact toughness, the furnace charge must be pure, and high-quality ductile iron pig iron should be selected. The impurities such as manganese, phosphorus, sulfur and titanium in the raw materials must be controlled at the lowest level, and the content of trace elements such as BP, BI, SB and TE It must be below 10PPM, and the content of impurity elements in scrap steel should be controlled at the lowest level.

[0024] (2) Electric Furnace Melting

[0025] Use a 12T medium frequency induction furnace to melt, heat the charge to 1500-1520°C, after testing, adjust the composition to 1450-1460°C, and control the pouring temperature at 1350±10°C

[0026] (3) Spheroidization treatment

[0027] The spheroidization treatment process adopts the flushing method spheroidization treatment process, and the spheroidizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com