Method and device for preparing cerium-based rare earth polishing powder by virtue of spray pyrolysis

A rare earth polishing powder and spray thermal decomposition technology is applied in the field of materials to achieve the effects of simplifying the complex structure of the equipment, avoiding the consumption of raw materials and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The structure of the device used is as figure 1 As shown, it includes a roasting furnace 1 and a cyclone separation device. The outside of the roasting furnace 1 is covered with a heating and heat preservation device 2. The inlet at the bottom of the roasting furnace 1 is connected to the blowing pipe 16, and the blowing pipe 16 is communicated with the liquid inlet tank 13. The liquid inlet tank 13 is connected to the The outlet of the air compressor 12 is connected; the cyclone separation device is composed of a first-stage cyclone separator, a second-stage cyclone separator and a third-stage cyclone separator in series, and the inlet of the first-stage cyclone separator 3 is connected with the outlet of the roasting furnace 1, and the first-stage cyclone separator 3 is connected with the outlet of the roasting furnace 1. The air outlet of the cyclone separator 3 is connected with the inlet of the secondary cyclone separator 5, the air outlet of the secondary cyclone s...

Embodiment 2

[0066] Device structure is the same as embodiment 1;

[0067] Method is with embodiment 1, and difference is:

[0068] The concentration of cerium chloride in the solution is 10g / L, NH 4 The concentration of F is 5g / L;

[0069] The temperature of the roasting furnace is 1700°C, the roasting time is 1s, the air flow rate during the injection process is 8000L / h, and the flow rate of the solution is 120L / h;

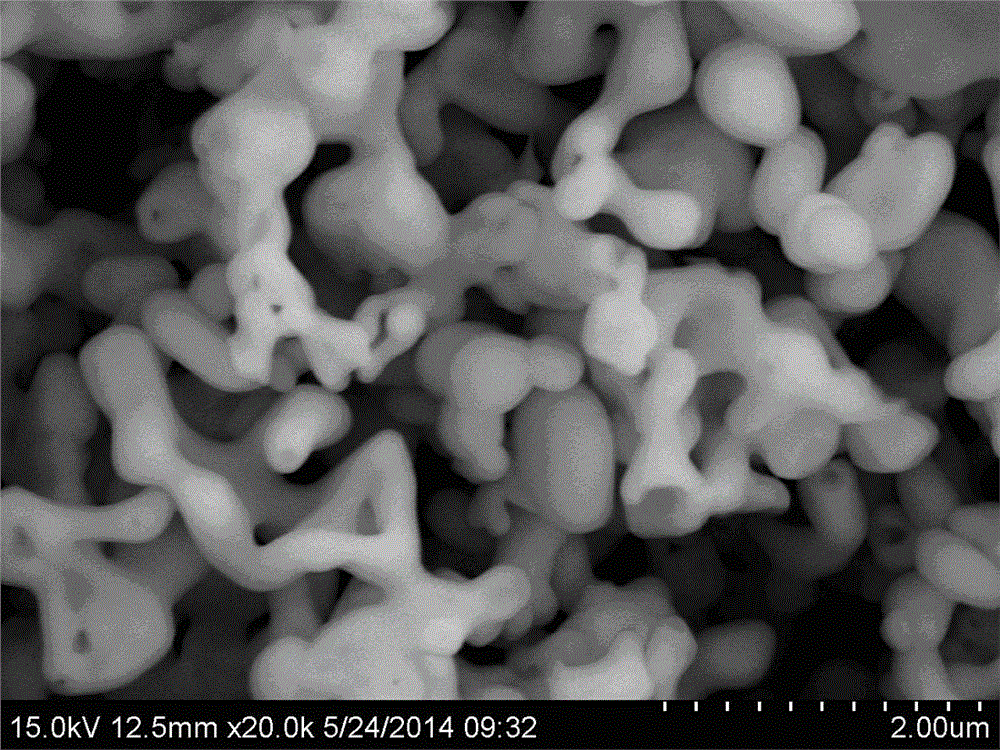

[0070] Cerium-based rare earth polishing powder, containing CeO by weight percentage 2 97.13%, the rest is CeF 3 and impurities, the weight content of impurities is 0.03%; the scanning electron microscope image of cerium-based rare earth polishing powder is as follows Figure 4 As shown, the XRD pattern is as Figure 5 shown;

[0071] The grinding force test of the cerium-based rare earth polishing powder was carried out, and the continuous grinding time was up to 56 hours.

Embodiment 3

[0073] Device structure is the same as embodiment 1;

[0074] Method is with embodiment 1, and difference is:

[0075] The concentration of cerium chloride in the solution is 100g / L, NH 4 The concentration of F is 50 g / L;

[0076] The temperature of the roasting furnace is 800°C, the roasting time is 40s, the air flow rate during the injection process is 800L / h, and the flow rate of the solution is 20L / h;

[0077] Cerium-based rare earth polishing powder, containing CeO by weight percentage 2 82.78%, the rest is CeF 3 And impurity, the weight content of impurity 0.04%; The scanning electron microscope picture of cerium-based rare earth polishing powder is as Figure 6 As shown, the XRD pattern is as Figure 7 shown;

[0078] The cerium-based rare earth polishing powder was subjected to a grinding force test, and the continuous grinding time was up to 63 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com