Rotor spinning rubber roller

A technology of rotor spinning and cots, which is applied to spinning machines, textiles, papermaking, and drafting equipment, etc. It can solve the problems of abnormal production, short service life, and easy winding, etc., and achieves improved antistatic winding effect , Reduce the maintenance cycle and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

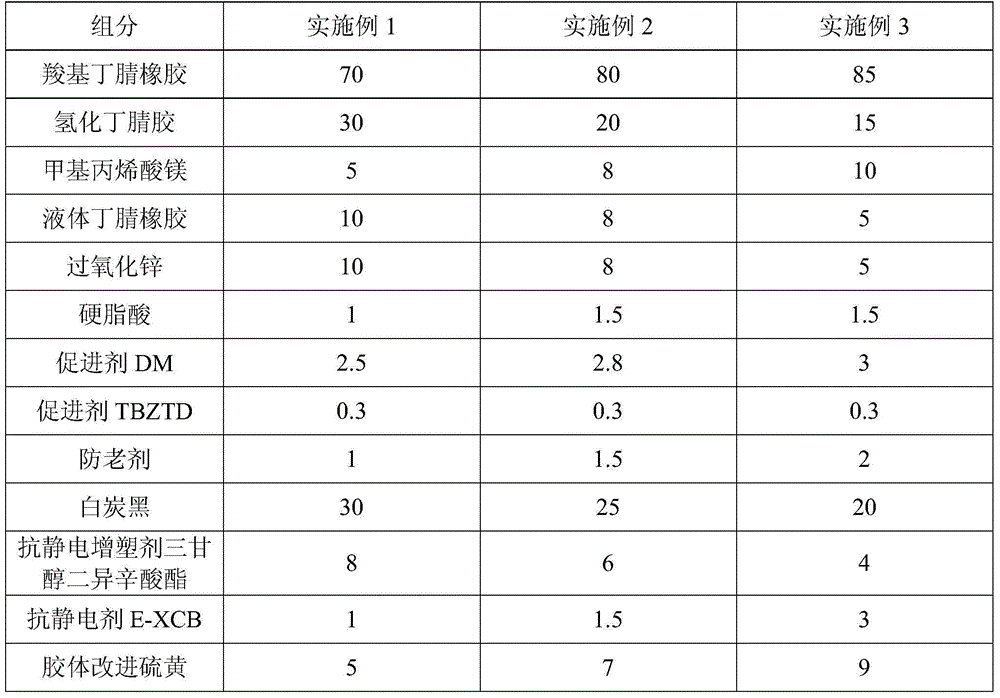

[0016] Table 1 shows the parts by weight of each component in the rotor spinning cots in Examples 1-3. The raw materials are accurately weighed according to the ratio of the raw materials, and then the open mill is used for masticating and gluing. The rubber mixer is mixed to make rubber products.

[0017] Table 1 Formulas of three kinds of rotor spinning cots

[0018]

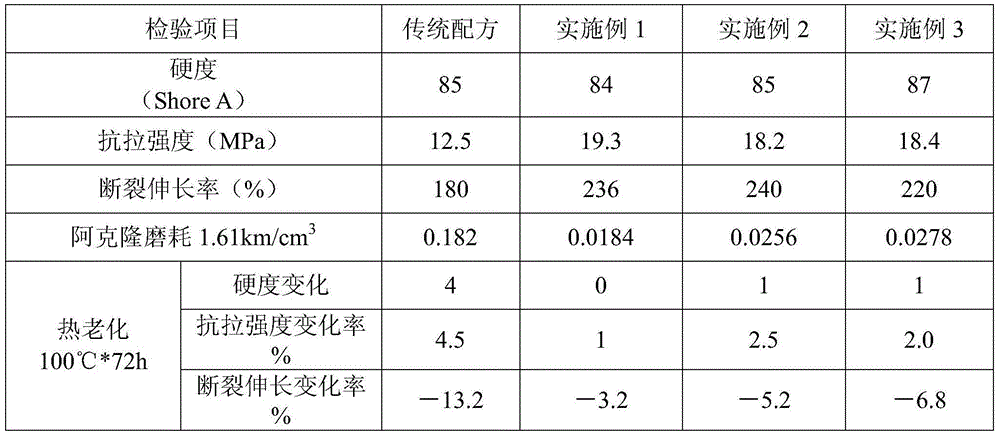

[0019] Using the rotor spinning cots of the traditional formula in the prior art as a comparative example, the three kinds of rubber products for preparing rotor spinning cots obtained in Examples 1 to 3 were prepared in accordance with "GB / T528-2009 ", "GB / T531.1-2008", "GB / T1689-1998", "GB / T3512-2001" testing standards were respectively tested for tensile stress-strain properties, hardness, thermal aging, etc. The results are shown in Table 2 Show:

[0020] Table 2

[0021]

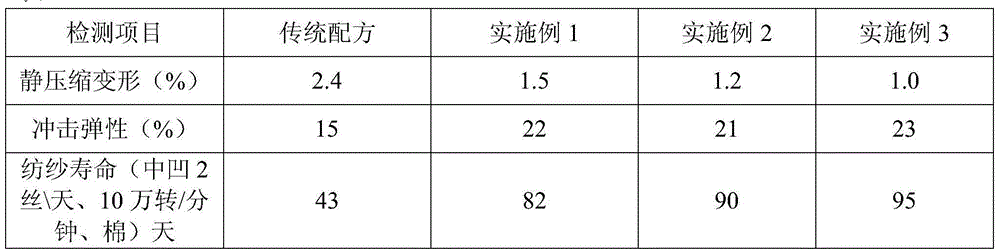

[0022] As can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com