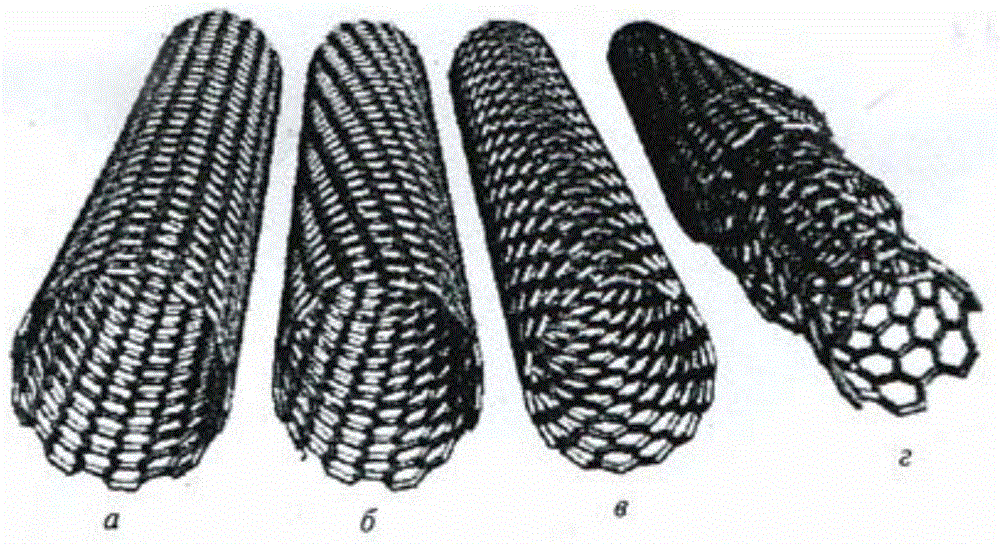

Method for preparing high-dispersity carbon nano tube modified asphalt

A carbon nanotube modification and high dispersion technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of high price, the performance of modified asphalt has yet to be studied, and the microstructure is damaged, so as to achieve cost saving and retention. High-quality performance, no damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

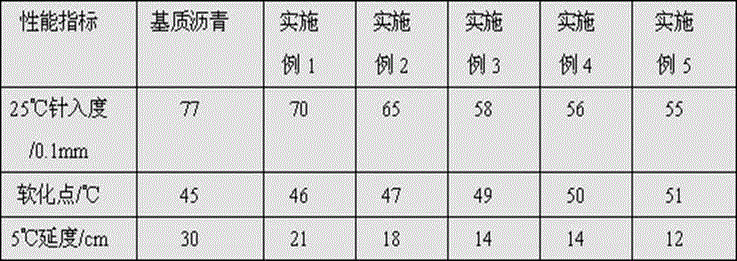

Embodiment 1

[0034] 1) Heat the base asphalt to a liquid state (110°C), pour it into a mixing cup, and weigh it;

[0035] 2) Weigh the carboxylated carbon nanotube material according to 1% of the weight of the pitch (the carboxyl ratio is 2%); weigh the sodium dodecylbenzenesulfonate according to 0.3% of the weight of the pitch;

[0036] 3) Add the carboxylated carbon nanotube material and sodium dodecylbenzenesulfonate weighed in the previous step into the asphalt, extend the working part of the shearing machine into the asphalt, set the speed at 3000 rpm, and work 20min, the shear temperature is 160°C.

Embodiment 2

[0038] 1) Heat the base asphalt to a liquid state (120°C), pour it into a mixing cup, and weigh it;

[0039] 2) Weigh carboxylated carbon nanotube material according to 2% of pitch weight (carboxyl ratio is 2%); weigh sodium dodecylbenzenesulfonate according to 0.4% of pitch weight;

[0040] 3) Add the carboxylated carbon nanotube material and sodium dodecylbenzenesulfonate weighed in the previous step into the asphalt, extend the working part of the shearing machine into the asphalt, set the speed at 4000 rpm, and work 30min, the shear temperature is 170°C.

Embodiment 3

[0042] 1) Heat the base asphalt to a liquid state (130°C), pour it into a mixing cup, and weigh it;

[0043] 2) Weigh carboxylated carbon nanotube material according to 3% of pitch weight (carboxyl ratio is 2%); weigh sodium dodecylbenzene sulfonate according to 0.5% of pitch weight;

[0044] 3) Add the carboxylated carbon nanotube material and sodium dodecylbenzenesulfonate weighed in the previous step into the asphalt, extend the working part of the shearing machine into the asphalt, set the speed at 5000 rpm, and work 40min, the shear temperature is 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com