Master batch for improving durability of polyglycolide (PGA) and preparation method of master batch

A polyglycolide, durable technology, used in the field of degradable plastic additives, can solve the problems of high melting processing temperature, PGA molecular weight drop, poor thermal stability, etc., to achieve easy operation, improve hydrolysis resistance, reduce degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

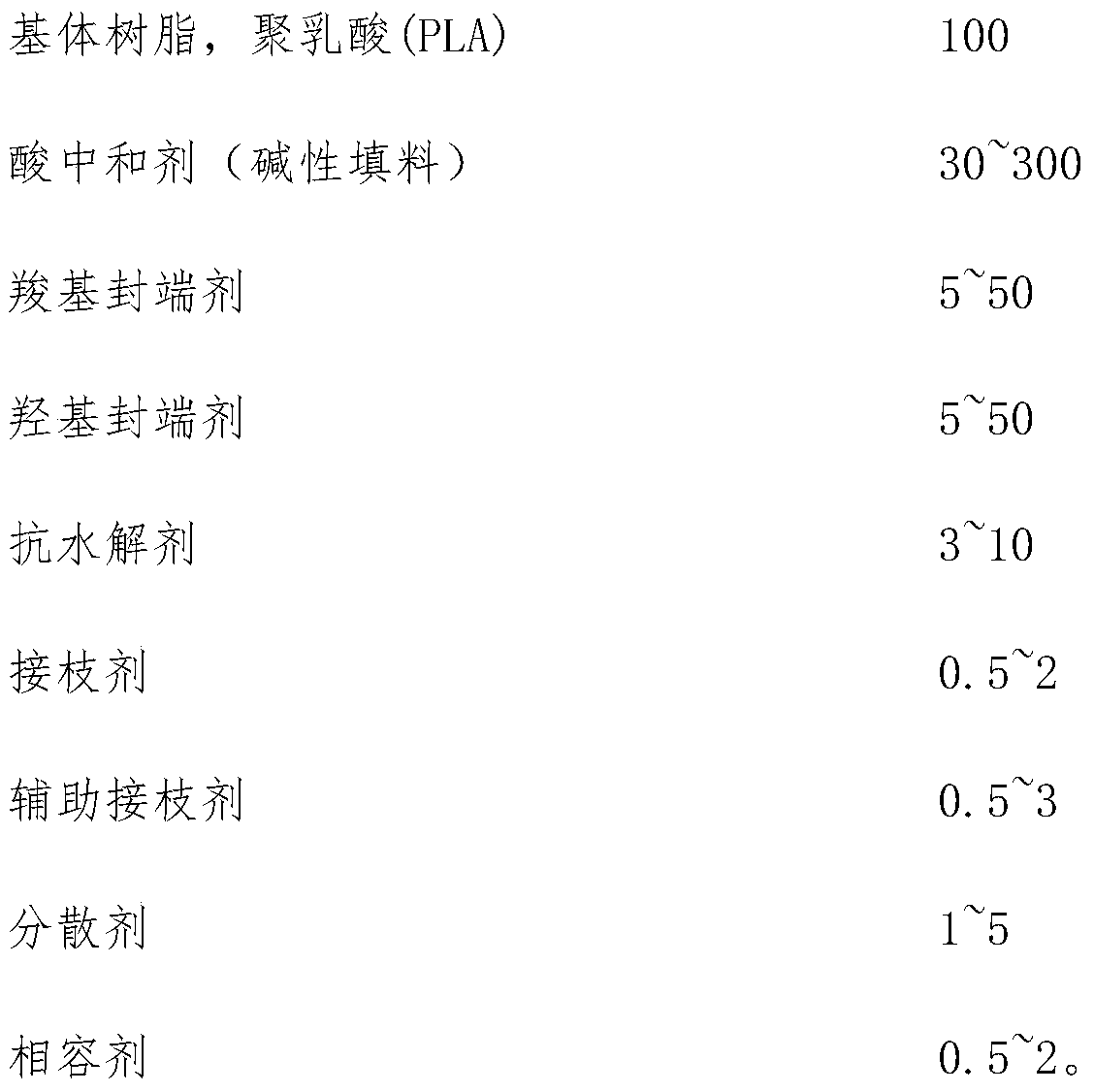

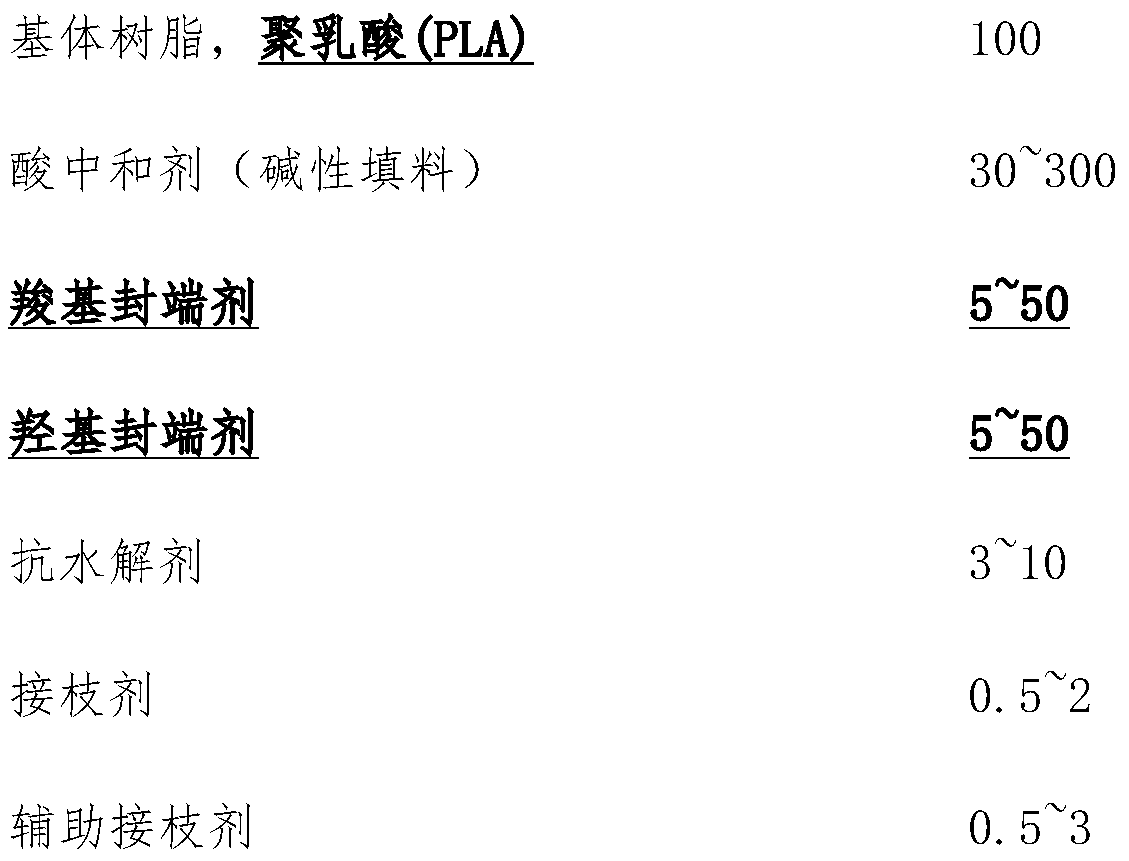

[0048] A masterbatch for improving the durability of polyglycolide, the preparation method of which is as follows:

[0049] ① Weigh 100 parts by mass of polylactic acid PLA, 30 parts of acid neutralizing agent calcium carbonate, 5 parts of polycarbodiimide as carboxyl-terminated agent, 5 parts of toluene diisocyanate as hydroxyl-terminated agent, and 5 parts of anti-hydrolysis agent vinyltrimethoxy 10 parts of base silane, 2 parts of grafting agent dicumyl peroxide, 3 parts of auxiliary grafting agent polyvinyl acetate (molecular weight 100,000), 5 parts of dispersant calcium oleate were mixed in a high mixer for 5 minutes, and then mixed in Extrude and granulate at 180-210°C in a twin-screw extruder;

[0050] ② Mix the granules obtained in step ① with 0.5 parts of compatibilizer titanium acetylacetonate in a high mixer for 5 minutes, and then extrude and granulate them in a twin-screw extruder at 150-180 ° C to obtain the improved Polyglycolide durability masterbatch.

[00...

Embodiment 2

[0055] range needs

[0056] A masterbatch for improving the durability of polyglycolide, the preparation method of which is as follows:

[0057] ①Weigh 100 parts by mass of polylactic acid PLA, 300 parts of acid neutralizing agent calcium carbonate, 50 parts of carboxy-blocking agent monomer carbodiimide, 5 parts of hydroxyl-blocking agent hexamethylene diisocyanate, anti-hydrolysis agent 3 parts of vinyltriethoxysilane, 0.5 parts of grafting agent 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, auxiliary grafting agent polyvinyl acetate (molecular weight 10 10,000) 0.5 parts, 3 parts of dispersant calcium oleate were mixed in a high mixer for 5 minutes, and then extruded and granulated in a twin-screw extruder at 180-210 °C;

[0058] ② Mix the granules obtained in step ① with 2 parts of compatibilizer in a high mixer for 5 minutes, and then extrude and granulate them in a twin-screw extruder at 150-180 ° C to obtain the polyglycol compound of the present invention. Masterbatc...

Embodiment 3

[0063] With embodiment 1, but acid neutralizer consumption obviously increases

[0064] ① Weigh 100 parts by mass of polylactic acid PLA, 250 parts of acid neutralizing agent calcium carbonate, 5 parts of polycarbodiimide as carboxyl-terminated agent, 5 parts of toluene diisocyanate as hydroxyl-terminated agent, and 5 parts of anti-hydrolysis agent vinyltrimethoxy 10 parts of base silane, 2 parts of grafting agent dicumyl peroxide, 3 parts of auxiliary grafting agent polyvinyl acetate (molecular weight 100,000), 5 parts of dispersant calcium oleate were mixed in a high mixer for 5 minutes, and then mixed in Extrude and granulate at 180-210°C in a twin-screw extruder;

[0065] ② Mix the granules obtained in step ① with 0.5 parts of compatibilizer titanium acetylacetonate in a high mixer for 5 minutes, and then extrude and granulate them in a twin-screw extruder at 150-180 ° C to obtain the improved Polyglycolide durability masterbatch.

[0066] Table 1 lists the evaluation te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com