Treatment method for fused ring compound wastewater

A compound and wastewater technology, applied in the separation/purification of carboxylic acid compounds, boron oxide compounds, chemical instruments and methods, etc., can solve the problems of high cost and inability to recycle waste water of polycyclic compounds, so as to reduce the cost of treatment, The effect of improving market competitiveness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

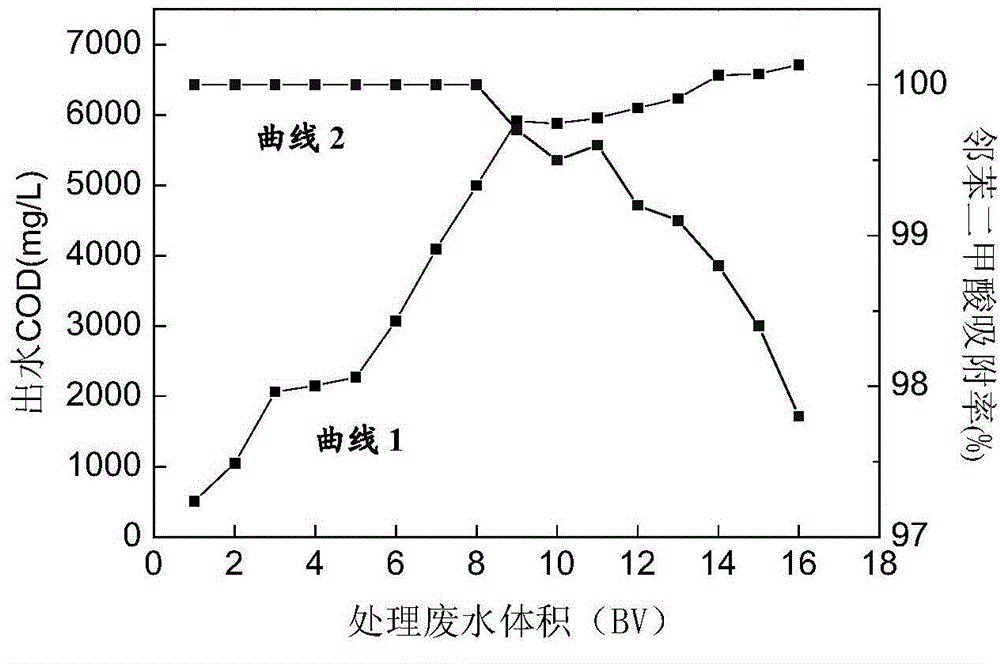

Embodiment 1

[0052] (1) Put 120ml of HYA-106 macroporous resin (Xi'an Hanyu Resin Technology Co., Ltd.) into the packed exchange column, leaving a 3-5cm water layer on it. The condensed ring compound wastewater is first adsorbed with activated carbon with a mass fraction of 0.1% for 30 minutes, the color changes from red to light brown, and then passes through the resin layer at a flow rate of 1BV / hr (1 times the resin volume per hour), and the column material liquid is periodically sampled and analyzed. COD and the content of phthalic acid in the feed liquid, when the COD value of the wastewater discharged from the column is higher than 3000mg / L, stop passing the column. After the resin stops treating wastewater, first use 1BV of deionized water to replace the wastewater at a rate of 1BV / hr, and then use 2BV of 4% sodium hydroxide solution to analyze the macroporous resin. The analysis temperature is 70-80°C. The flow rate of the sodium oxide solution is 1BV / hr. After the analysis is comp...

Embodiment 2

[0065] (1) Put 120ml of HYA-106 macroporous resin into the packed exchange column respectively, leaving a 3-5cm water layer on it. The condensed ring compound wastewater is first adsorbed with activated carbon with a mass fraction of 0.05% for 30 minutes, the color changes from red to light brown, and then passes through the resin layer at a flow rate of 2BV / hr (2 times the resin volume per hour), and the column feed liquid is periodically sampled and analyzed. COD and the content of phthalic acid in the feed liquid, when the COD value of the wastewater discharged from the column is higher than 3000mg / L, stop passing the column. After the resin stops treating wastewater, first use 1BV of deionized water to replace the wastewater at a rate of 1BV / hr, and then use 2BV of 10% sodium hydroxide solution to analyze the macroporous resin. The analysis temperature is 70-80°C. The flow rate of the sodium oxide solution is 1BV / hr. After the analysis is completed, the resin is washed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com