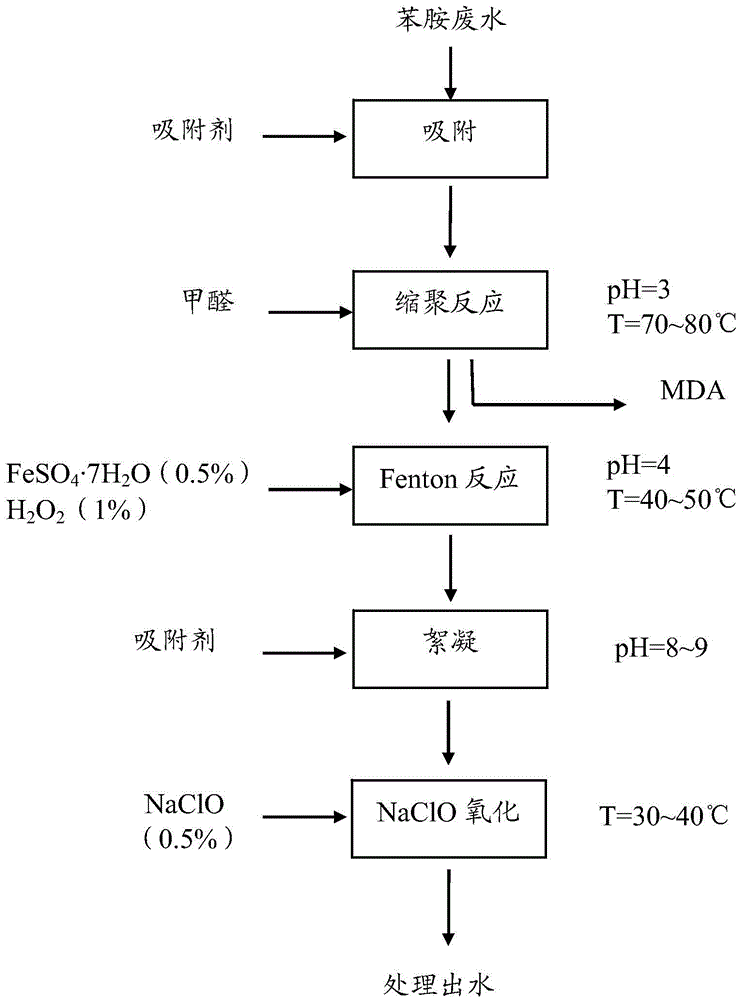

A kind of treatment method of aniline waste water

A treatment method and technology for wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing the salt content of wastewater, high one-time investment, and highly toxic intermediate products and other problems, to achieve the effect of improving the ability of oxidative degradation, simple process flow, easy and cheap medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 1g / L activated carbon powder (based on the original wastewater volume) to aniline wastewater (original COD is 24800mg / L, aniline concentration is 8211mg / L), stirring and adsorbing for 0.5 hours, and after filtration, clear liquid I is obtained; clear liquid I is concentrated After adjusting the pH to 3 with hydrochloric acid and heating to 70°C, add 6g / L (the volume of the supernatant I as the benchmark) formaldehyde solution (the mass fraction of the formaldehyde solution is 37%), and adjust the pH to 7 after 1 hour of insulation and stirring reaction After flocculation and filtration, MDA and supernatant II were obtained. The mass of MDA is about 1% of the mass of clear liquid I, the purity of MDA is 96.8%, and the COD of clear liquid II is 1300 mg / L; the pH of clear liquid II is adjusted to 4, and the pH of clear liquid II is adjusted to 8 after 1 hour of Fenton reaction. Carry out flocculation, filter the COD of the filtrate to be 600mg / L, add 0.3g / L of availabl...

Embodiment 2

[0057] Add 1g / L activated carbon powder (based on the original wastewater volume) to the aniline mixed wastewater (original COD is about 20000mg / L), stir and adsorb for 0.5 hours, and filter to obtain clear liquid I; 3 and heated to 70° C., add 4g / L (the volume of the supernatant I as the benchmark) formaldehyde solution (the mass fraction of the formaldehyde solution is 37%), and adjust the pH to 7 for flocculation and filtration after thermal insulation and stirring reaction for 1 hour to obtain Solid and supernatant II, the obtained solid product accounts for 0.75% of the mass of supernatant I. The detection shows that it is a recoverable compound, and the COD of the supernatant is 2010 mg / L; the pH of supernatant II is adjusted to 4, and the Fenton reaction is performed for 1 hour. Then, the pH was adjusted to 8 for flocculation and activated carbon powder was added to stir and decolorize, and the filtrate was filtered to obtain a transparent and clear filtrate with a COD o...

Embodiment 3

[0059] Add 1g / L diatomaceous earth (based on the original wastewater volume) to aniline mixed wastewater (original COD is about 20000mg / L), stir and adsorb for 0.1 hour, and filter to obtain clear liquid I; clear liquid I is adjusted to pH with concentrated hydrochloric acid After reaching 5 and heating to 80°C, add 4g / L (the volume of the supernatant I as the benchmark) formaldehyde solution (the mass fraction of the formaldehyde solution is 37%), and adjust the pH to 8 for flocculation and filtration after thermal insulation and stirring reaction for 1 hour. The solid and supernatant II were obtained. The solid product accounted for 0.60% of the mass of the supernatant I. The detection showed that it was a recoverable compound, and the COD of the supernatant was 4709 mg / L; the pH of the supernatant II was adjusted to 4, and the Fenton reaction was performed for 1 hour. Then adjust the pH to 8 for flocculation, and filter to obtain a filtrate that is transparent and slightly y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com