Nitrogen-doped modified porous carbon with high specific surface area and preparation method thereof

A high specific surface area, nitrogen-doped technology, applied in the field of nanomaterials, can solve the problems of not being able to significantly improve the performance of carbon materials, the single type of nitrogen-containing functional groups, and not being suitable for practical applications, etc., to achieve large-scale mass production, wide pore size distribution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

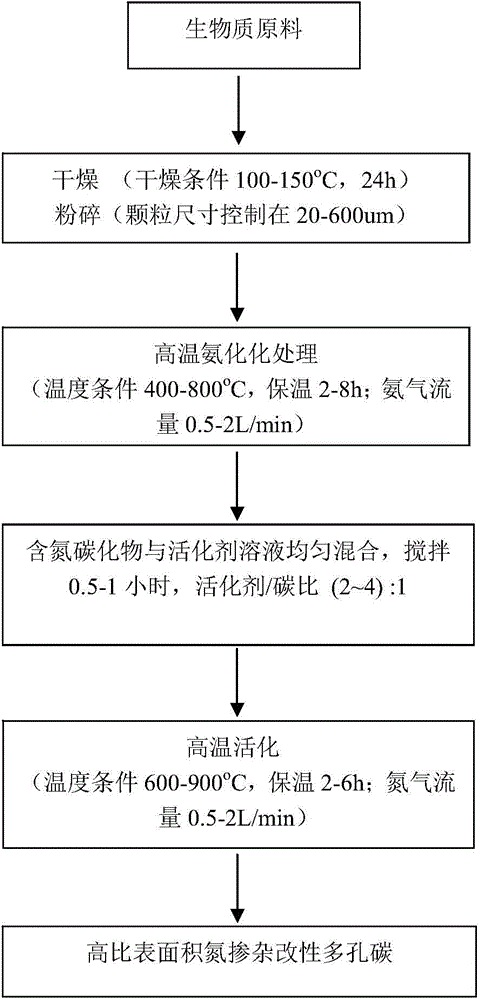

[0030] Such as figure 1 as shown, figure 1 It is a flow chart of the preparation method of nitrogen-doped modified porous carbon with high specific surface area shown in the embodiment. A method for preparing nitrogen-doped modified porous carbon with high specific surface area, comprising the following steps:

[0031] Put the biomass raw material corncob in a blast drying oven, dry at a temperature of 100°C for at least 24 hours, crush and sieve, control the particle size to 200um, put the particles into the material boat, and place the material boat in the atmosphere furnace In the process, the furnace chamber is vacuumed, and nitrogen-containing carbides are obtained after high-temperature ammonification treatment in an ammonia atmosphere. The ammonia gas flow rate is 0.5L / min, and the temperature is programmed from room temperature to 800°C, and the treatment time is 2 hours. , the heating rate is 5°C / min; then the nitrogen-containing carbide is dispersed in a potassium ...

Embodiment 2

[0034] A method for preparing porous carbon doped with high specific surface area and high nitrogen content, comprising the following steps:

[0035] Put the biomass raw material coconut shell in a blast drying oven, dry at a temperature of 150°C for at least 24 hours, crush and sieve, control the particle size to 500um, put the particles into the material boat, and place the material boat in the atmosphere furnace In the process, vacuumize the furnace chamber and carry out high-temperature ammonification treatment in an ammonia atmosphere to obtain nitrogen-containing carbides. The flow rate of ammonia gas is 2L / min, and the temperature is programmed from room temperature to 700°C. The treatment time is 4 hours. The speed is 3°C / min; then the nitrogen-containing carbide is dispersed in a potassium hydroxide solution with a concentration of 60%, the mass mixing ratio of the potassium hydroxide solution and the carbide is 2:1, the stirring time is 0.5 hours, and after drying Th...

Embodiment 3

[0037] A method for preparing porous carbon doped with high specific surface area and high nitrogen content, comprising the following steps:

[0038]Put the biomass raw bamboo leaves in a blast drying oven and dry them at a temperature of 120°C for at least 24 hours. After crushing and sieving, the particle size is controlled to 25um. Put the particles into the material boat, and place the material boat in the atmosphere furnace In the process, nitrogen-containing carbides were obtained after high-temperature ammonification treatment in an ammonia atmosphere. The nitrogen flow rate was 1.25L / min, and the temperature was programmed from room temperature to 500°C. The treatment time was 2 hours, and the heating rate was 4°C / min. ; Then disperse the nitrogen-containing carbide in a saturated potassium hydroxide solution with a concentration of 50%, the mass mixing ratio of the potassium hydroxide solution and the carbide is 3:1, the stirring time is 0.75 hours, and the alkali-carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com