Method for manufacturing liquid inkjet head, liquid inkjet head, and printing apparatus

A technology of liquid inkjet head and manufacturing method, applied in the field of liquid inkjet head and printing equipment, liquid inkjet head manufacturing, capable of solving problems such as affecting printing speed, lowering printing quality, liquid ink backflow, etc., and achieving increased printing speed and printing accuracy, improve accuracy, improve printing speed and print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

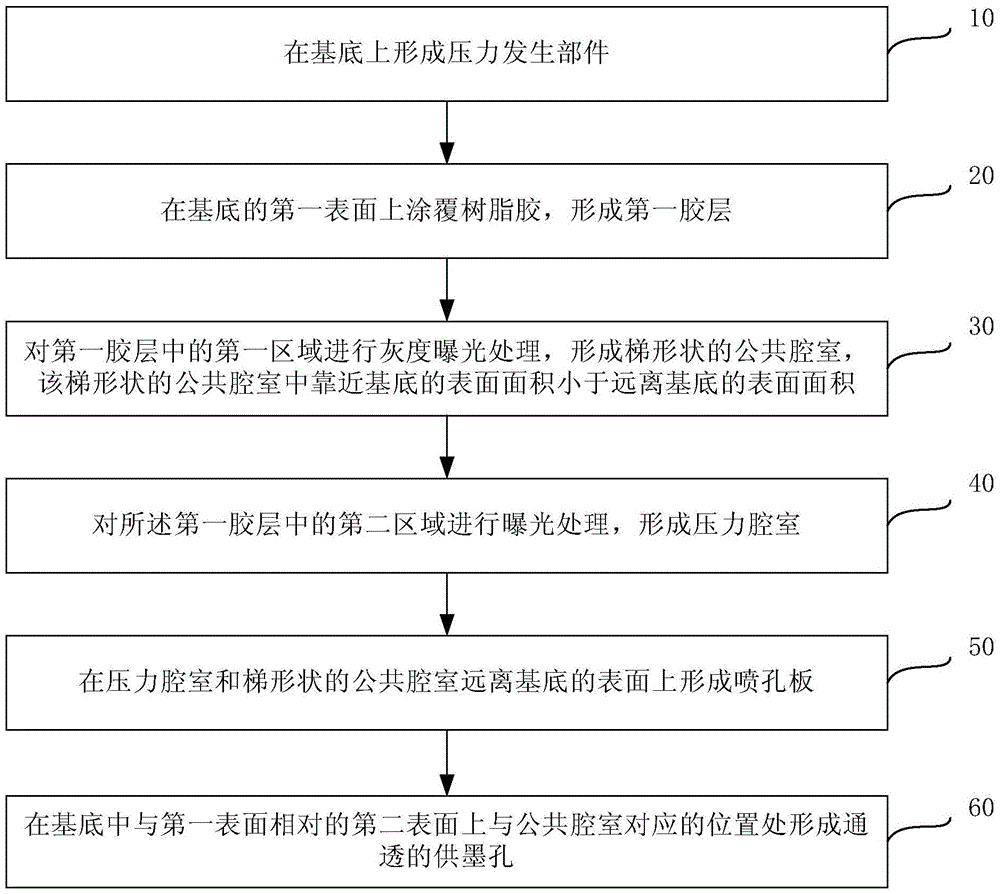

[0047] figure 1 It is a flow chart of the manufacturing method of the liquid inkjet head provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the manufacturing method of the liquid inkjet head may include:

[0048] Step 10, forming a pressure generating component on the substrate.

[0049] Wherein, the substrate may be a silicon substrate or a glass substrate, and a silicon substrate is used in this embodiment. The function of the pressure generating part is to drive the ink in the pressure chamber to be ejected from the nozzle hole and printed on the printing medium, which can be various forms of devices, such as piezoelectric elements, thin film resistors, etc. In this embodiment, the piezoelectric element is taken as an example to specifically describe the method for forming the pressure generating member.

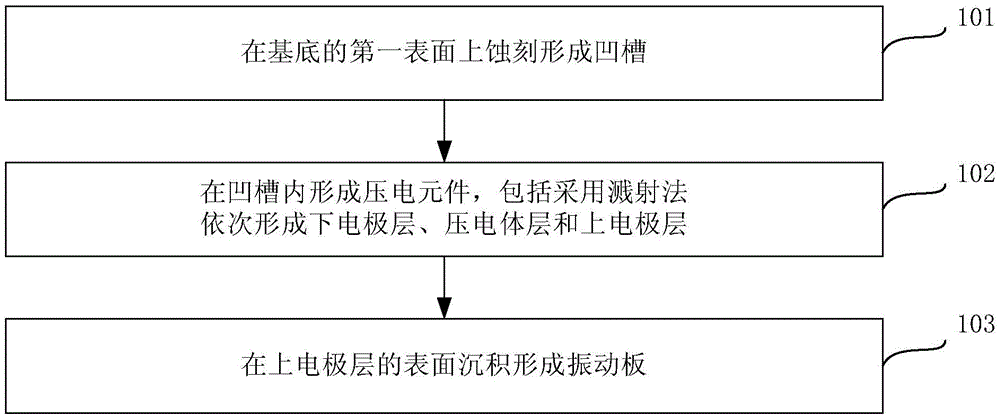

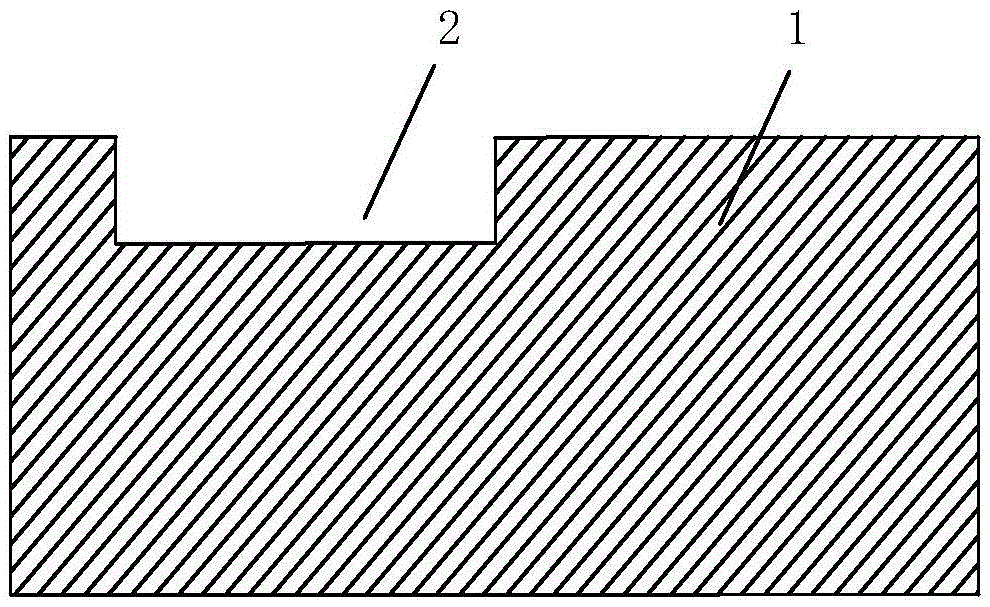

[0050] Specifically, refer to figure 2 , figure 2 It is a flowchart of a method for forming a pressure generating member in the method ...

Embodiment 2

[0101] This embodiment provides another method for forming a pressure generating component on the basis of the above embodiments, which may specifically include:

[0102] The vibrating plate 4 is formed by depositing on the first surface of the substrate 1 .

[0103] Specifically, it can be formed by low-pressure chemical vapor deposition or plasma-enhanced chemical vapor deposition, and the material of the vibrating plate 4 can be SiO 2 、Si 3 N 4 or SiO 2 -Si 3 N 4 stacks. This step can refer to Figure 10 , Figure 10 It is a schematic structural diagram of forming a vibrating plate on the surface of a substrate in the method for manufacturing a liquid inkjet head provided in Embodiment 2 of the present invention.

[0104] The piezoelectric element 3 is formed on the surface of the vibrating plate 4 away from the base 1 .

[0105] Specifically, the lower electrode layer can be formed by sputtering, the piezoelectric layer can be formed by sol-gel method, and the upp...

Embodiment 3

[0108] This embodiment provides yet another method for forming a pressure generating component on the basis of the above embodiments, which specifically includes:

[0109] A thin film resistance layer 19 is deposited on the first surface of the substrate 1 .

[0110] Specifically, the thin film resistance layer 19 can be deposited on the substrate 1 , and the material of the thin film resistance layer 19 can be one of tantalum aluminum alloy, nickel cadmium alloy, tungsten silicon nitride and titanium nitride. Can refer to Figure 13 , Figure 13 It is a schematic structural diagram of forming a thin-film resistance layer on a substrate in the method for manufacturing a liquid inkjet head provided in Embodiment 3 of the present invention.

[0111] For the forming method of other components in the liquid inkjet head, reference may be made to the technical solutions provided in the above embodiments, and details will not be repeated here. The formed liquid inkjet head structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com