A kind of composition for manufacturing switch grinding wheel and its preparation method and use

A technology of composition and grinding wheel, which is applied in the direction of manufacturing tools, grinding/polishing equipment, abrasives, etc., can solve the problems of unstable grinding quality, low rotational strength, large grinding motor, etc., to ensure thermal performance and improve coating. , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

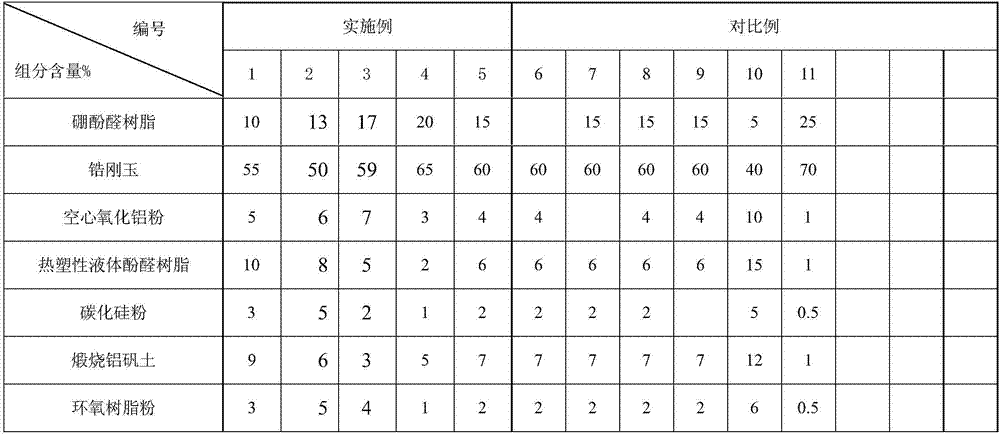

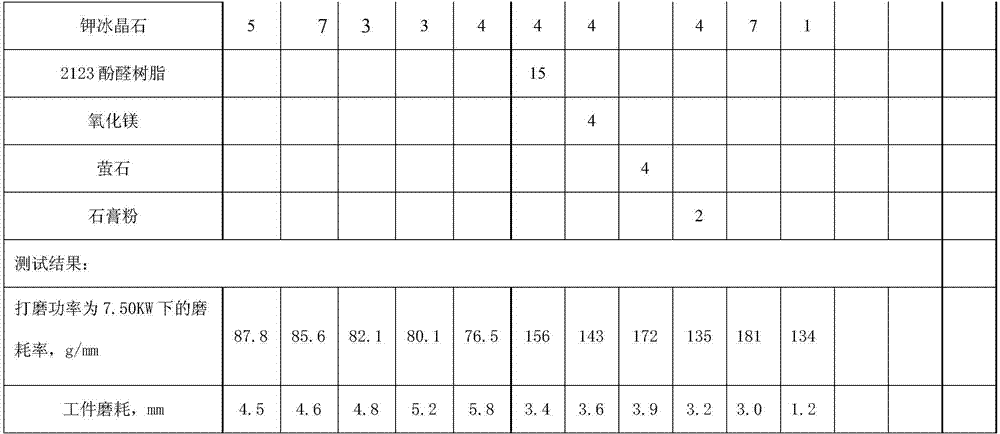

Examples

preparation example Construction

[0049] The preparation method comprises the following steps:

[0050] (1) First, in pot No. 1, zirconium corundum, epoxy resin powder and thermoplastic liquid phenolic resin are mixed evenly;

[0051] (2) Boron phenolic resin, hollow alumina powder, silicon carbide powder, calcined bauxite and potassium cryolite are mixed uniformly in No. 2 pot simultaneously;

[0052] (3) Put the mixed material obtained in step (1) and the mixed material obtained in step (2) into the No. 3 mixing pot and mix evenly, and keep it for 5-20 minutes;

[0053] (4) The mixture obtained in step (3) is hot-pressed and sintered at a high temperature;

Embodiment 1

[0055] The preparation technology of grinding wheel of the present invention is as follows:

[0056] (1) 55 parts of zirconium corundum, 3 parts of epoxy resin powder and 10 parts of thermoplastic liquid phenolic resin are mixed evenly;

[0057] (2) Mix 10 parts of boron phenolic resin, 5 parts of hollow alumina powder, 3 parts of silicon carbide powder (300 mesh fineness), 9 parts of calcined bauxite (800 mesh fineness) and 5 parts of potassium cryolite;

[0058] (3) Put the mixture obtained in step (1) and the mixture obtained in step (2) into the No. 3 mixing pot and mix evenly, and keep for 10 minutes;

[0059] (4) Hot press the mixture obtained in step (3), the pressure is 25Mpa, the pressure holding time is 40min, and the hot pressing temperature is 160°C, wherein, during the pressure holding process, the pressure is reduced to 0 within the first 10min Deflate, then quickly restore the pressure, repeat 3 times; high temperature sintering, the sintering temperature is 20...

Embodiment 2

[0061] The preparation technology of grinding wheel of the present invention is as follows:

[0062] (1) 50 parts of zirconium corundum, 5 parts of epoxy resin powder and 8 parts of thermoplastic liquid phenolic resin are mixed evenly;

[0063] (2) 13 parts of boron phenolic resin, 6 parts of hollow alumina powder, 5 parts of silicon carbide powder (fineness 500 mesh), 6 parts of calcined bauxite (fineness 1200 mesh) and 7 parts of potassium cryolite are mixed evenly;

[0064] (3) Enter the mixed material obtained in step (1) and the mixed material obtained in step (2) into the No. 3 mixing pot at the same time and mix evenly, and keep for 5 minutes;

[0065] (4) Hot press the mixture obtained in step (3), the pressure is 20Mpa, the pressure holding time is 30min, and the hot pressing temperature is 150°C, wherein, during the pressure holding process, the pressure is reduced to 0 within the first 10min Perform degassing, then quickly restore the pressure, repeat twice; high t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com