Process for preparing heat-resistant steel plate

A preparation process, heat-resistant technology, applied to the surface coating liquid device, polyester coating, surface pretreatment, etc., can solve the problems of difficult large-scale construction, poor metal adhesion, high production cost, etc., to achieve excellent Adhesion and processability, good heat resistance and hot hardness, and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

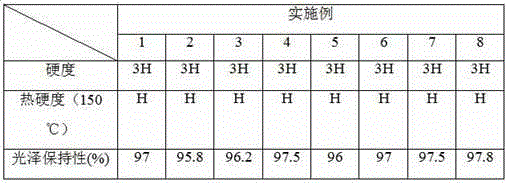

Examples

Embodiment 1

[0029] The heat-resistant steel plate involved in this embodiment is prepared by coating and baking the pre-coated steel plate with the base coating and the surface coating in sequence, wherein the base coating is applied to the surface of the pre-coated steel plate to form a base coating , by weight percentage, the base coating contains the following components:

[0030] Silicone modified polyester resin: 30%; filler: 20%;

[0031] Silicone coupling agent: 1%; Phthalate: 0.5%;

[0032] Solvent: 48.5%.

[0033] The surface coating is applied to the surface layer of the base coating film to form a surface coating film. In terms of weight percentage, the surface coating comprises the following components:

[0034] Silicone modified polyester resin: 40%; pigment: 10%;

[0035] Polyamide curing agent: 5%; Filler: 10%;

[0036] Siloxane coupling agent: 1.2%; Solvent: 33.8%.

[0037] The following is a further description of the composition of the above components:

[0038] Si...

Embodiment 2

[0047] The heat-resistant steel plate involved in this embodiment is prepared by coating and baking the pre-coated steel plate with the base coating and the surface coating in sequence, wherein the base coating is applied to the surface of the pre-coated steel plate to form a base coating , by weight percentage, the base coating contains the following components:

[0048] Silicone modified polyester resin: 50%; filler: 46%;

[0049] Silicone coupling agent: 2%; Phthalate: 1%;

[0050] Solvent: 1%.

[0051] The surface coating is applied to the surface layer of the base coating film to form a surface coating film. In terms of weight percentage, the surface coating comprises the following components:

[0052] Silicone modified polyester resin: 60%; pigment: 15%;

[0053] Polyamide curing agent: 7%; Filler: 15%;

[0054] Siloxane coupling agent: 1.8%; Solvent: 1.2%.

[0055] The following is a further description of the composition of the above components:

[0056] Silicone...

Embodiment 3

[0065] The heat-resistant steel plate involved in this embodiment is prepared by coating and baking the pre-coated steel plate with the base coating and the surface coating in sequence, wherein the base coating is applied to the surface of the pre-coated steel plate to form a base coating , by weight percentage, the base coating contains the following components:

[0066] Silicone modified polyester resin: 45%; filler: 46%;

[0067] Silicone coupling agent: 1.5%; Phthalate: 0.5%;

[0068] Solvent: 7%.

[0069] The surface coating is applied to the surface layer of the base coating film to form a surface coating film. In terms of weight percentage, the surface coating comprises the following components:

[0070] Silicone modified polyester resin: 55%; Pigment: 12%;

[0071] Polyamide curing agent: 6%; Filler: 14%;

[0072] Siloxane coupling agent: 1.5%; Solvent: 11.5%.

[0073] The following is a further description of the composition of the above components:

[0074] Sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com