Separation technology of specularite after reduction roasting

A technology of roasting and rear mirror, which is applied in flotation, solid separation, wet separation, etc. It can solve the problems of large roasting furnace processing capacity, inability to use industrial production, and reduce iron recovery rate, so as to save equipment and infrastructure investment, The effect of high recovery rate and reduction of treatment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

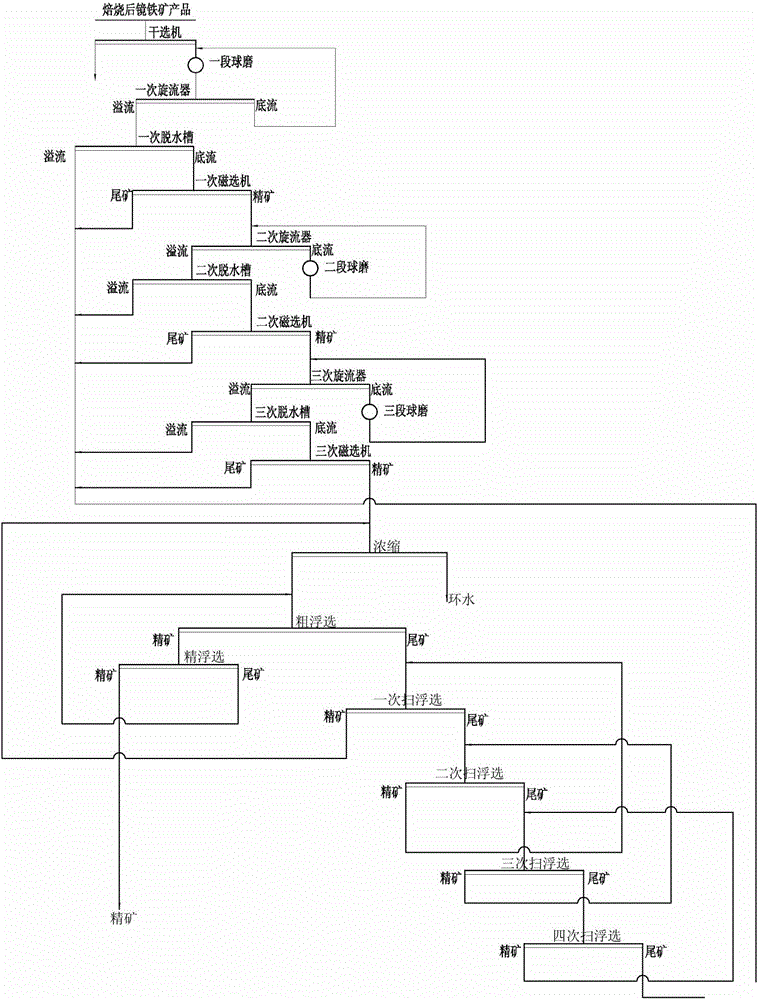

[0026] Such as figure 1 As shown, a sorting process for specularite after reduction roasting of the present invention includes a specularite reduction roasting system, which is characterized by:

[0027] a. The reduced-roasted, water-purified specularite product is pre-selected and thrown by a dry separator. The dry beneficiation concentrate is fed into a ball mill-cyclone closed circuit to enter the magnetic separation system; the present invention uses reduced-roasted specularite The ore is used as a feed before magnetic separation, which greatly enhances the magnetic properties of specularite iron oxide minerals. The specularite reduction roasting system feeds 15mm-50mm lump ore, and the product after reduction and roasting has a particle size of 0 mm -15mm, the dry concentrate yield rate is 90%, the grade is over 40%, and the iron recovery rate is 98%. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com