A self-cleaning polyvinylidene fluoride microporous membrane and its preparation method

A technology of polyvinylidene fluoride and microporous membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems affecting the strength of hollow fiber membranes, achieve high strength, good cleaning effect, and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

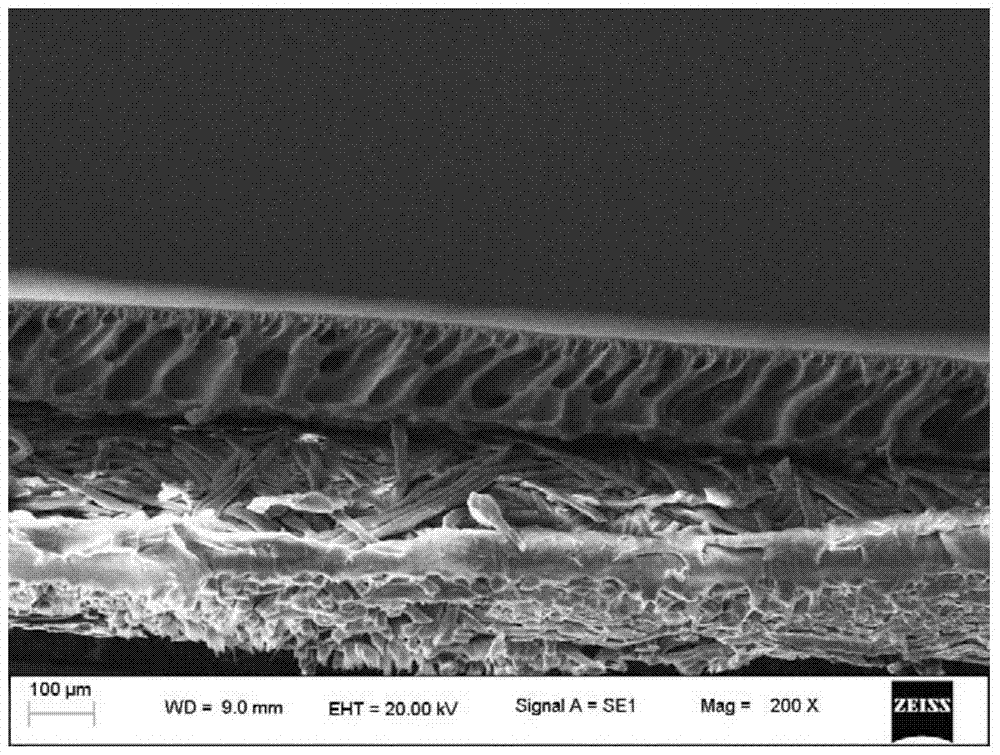

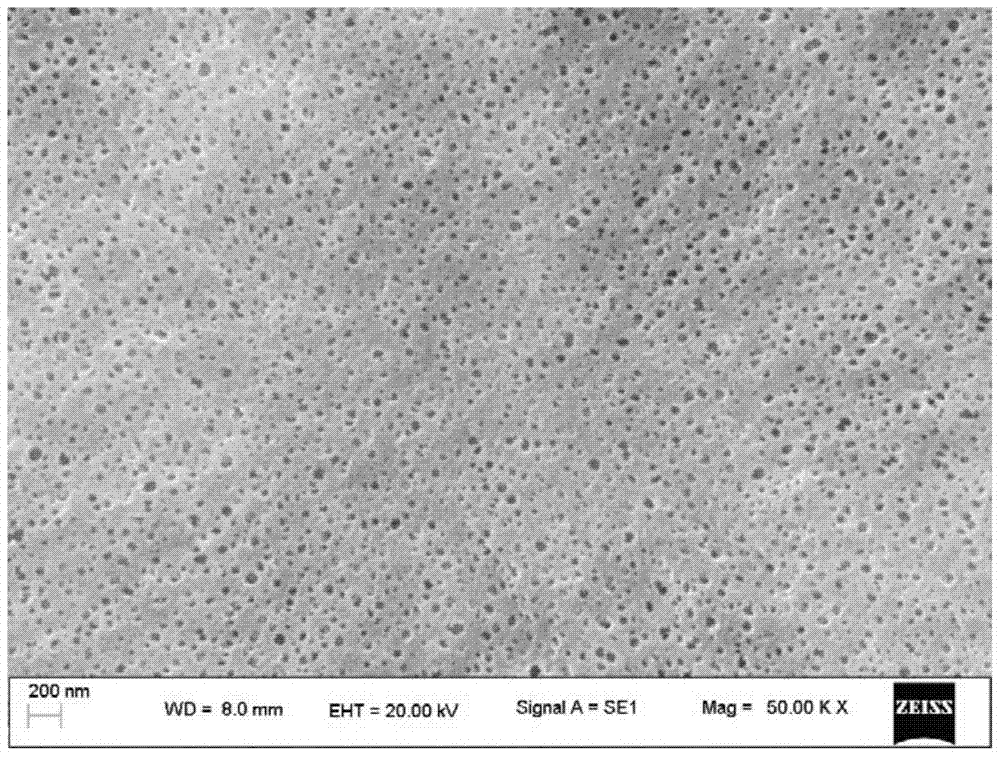

[0030] The preparation steps of the self-cleaning polyvinylidene fluoride flat microporous membrane are as follows:

[0031](1) Polyvinylidene fluoride, thermosensitive amphiphilic copolymer poly(N-isopropylacrylamide-r-methyl methacrylate) P(NIPAAM-r-MMA), porogen and solvent at temperature Stir evenly at 60°C, and obtain the casting solution after filtration and vacuum defoaming;

[0032] The mass percentages of polyvinylidene fluoride, thermosensitive amphiphilic copolymer poly(N-isopropylacrylamide-r-methyl methacrylate) P(NIPAAM-r-MMA), porogen and solvent are respectively: 14%, 1.5%, 8%, 76.5%, the molecular weight of PVDF is 6.9×10 5 , the thermosensitive amphiphilic copolymer poly(N-isopropylacrylamide-r-methyl methacrylate) P(NIPAAM-r-MMA) has a molecular weight of 1.5×10 4 The porogen is a mixture of polyethylene glycol 400 (5wt%) and polyvinylpyrrolidone K30 (3wt%); the solvent is N,N-dimethylformamide (DMF); the temperature sensitivity Amphiphilic copolymer poly...

Embodiment 2

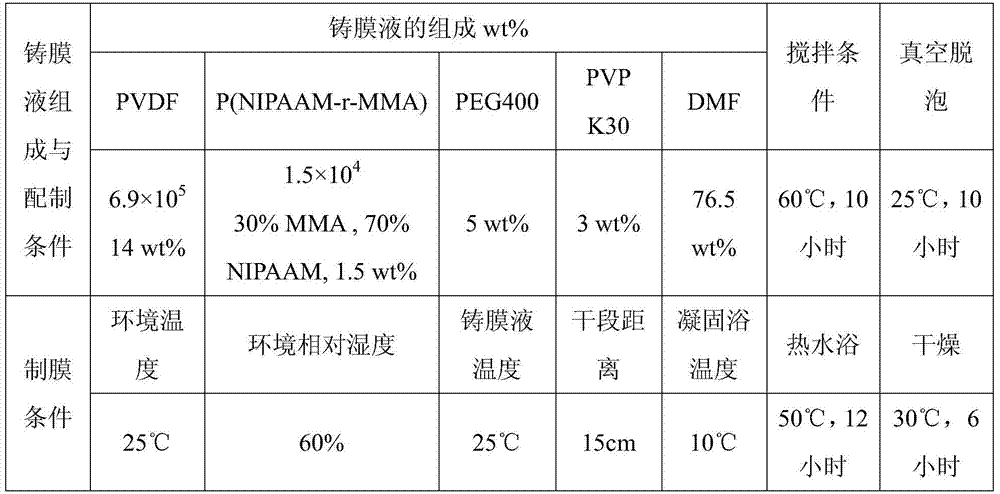

[0041] The preparation steps of the self-cleaning polyvinylidene fluoride flat microporous membrane in Example 2 are the same as in Example 1, but the composition, preparation conditions and film-making conditions of the casting solution are different from those in Example 1, see Table 2 for details.

[0042] Table 2

[0043]

[0044]

Embodiment 3

[0046] The preparation steps of the self-cleaning polyvinylidene fluoride flat microporous membrane in Example 3 are the same as in Example 1, but the composition, preparation conditions and film-making conditions of the casting solution are different from those in Example 1, see Table 3 for details.

[0047] table 3

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com