Preparation method of high-precision coating filter material

A production method and high-precision technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of easy filtration, poor folding resistance and wear resistance of glass fibers, and formation of protective films, so as to improve the filtration efficiency. Accuracy, extended service life, and improved corrosion resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of high-precision coating filter material of the present invention, comprises the steps:

[0031] 1. The woven 750g / ㎡ glass fiber filter cloth is subjected to heat cleaning treatment, and various additives on the surface of the fabric are removed by high temperature, so as to facilitate subsequent processing; the temperature of heat cleaning is 450°C to 500°C.

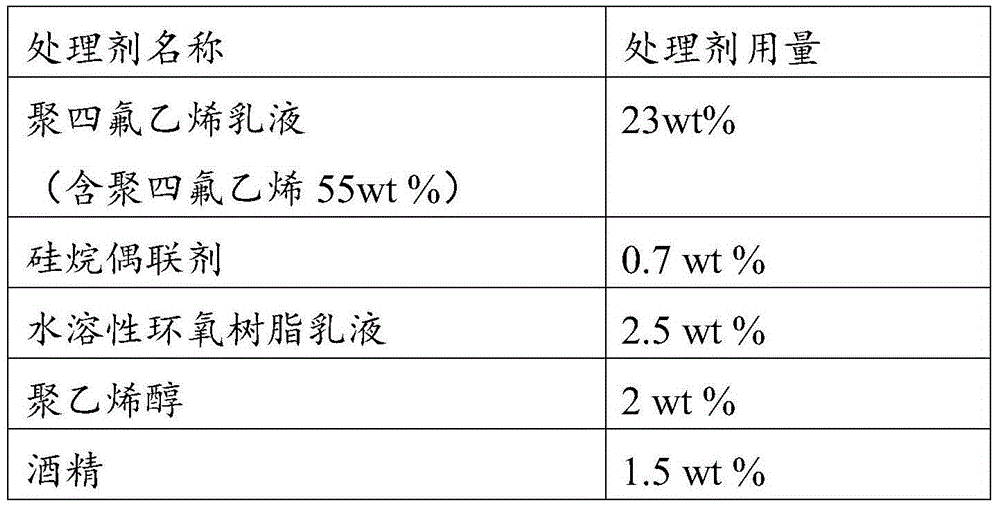

[0032] 2. The cleaned filter cloth is pre-impregnated, the impregnation speed is 5m / min, and the treatment formula is as follows:

[0033]

[0034] 3. The pretreated filter cloth enters the drying, drying and heat setting device for smoothing. The drying temperature is 160°C; the drying temperature is 220°C; the heat setting temperature is 290°C, and the speed of drying, drying, and heat setting is 2m / min. The drying zone can take away most of the moisture contained in the filter material with hot air. The temperature in the drying and setting area is high, so that the PTFE molecules ...

Embodiment 2

[0039] The preparation method of high-precision coating filter material of the present invention, comprises the steps:

[0040] 1. The woven 500g / ㎡ glass fiber filter cloth is subjected to heat cleaning treatment, and various additives on the surface of the fabric are removed by high temperature, so as to facilitate subsequent processing; the temperature of heat cleaning is 450°C to 500°C.

[0041] 2. The cleaned filter cloth is pre-impregnated, the impregnation speed is 6m / min, and the treatment formula is as follows:

[0042]

[0043]

[0044] 3. The pretreated filter cloth enters the drying, drying and heat setting device for smoothing. The drying temperature is 165°C; the drying temperature is 225°C; the heat setting temperature is 320°C, and the speed of drying, drying, and heat setting is 3m / min. The drying zone can take away most of the moisture contained in the filter material with hot air. The temperature in the drying and setting area is high, so that the PTF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com