Lithography apparatus with segmented mirror

A technology of lithography equipment and mirrors, applied in microlithography exposure equipment, optomechanical equipment, optics, etc., can solve problems such as large cost and space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

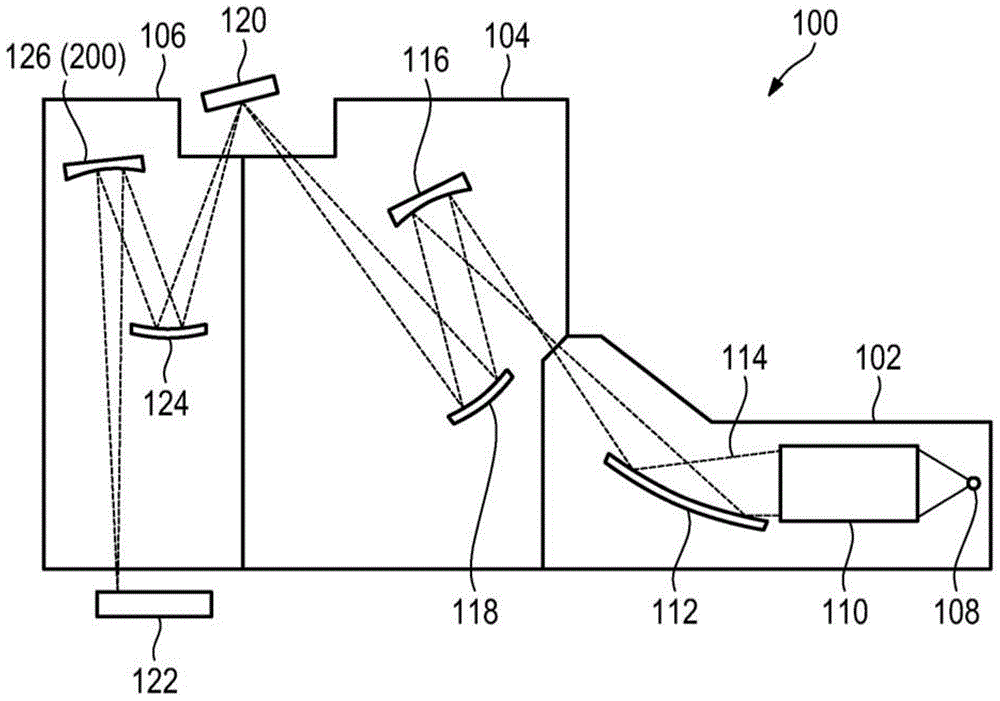

[0036] figure 1 A schematic diagram of an EUV lithography apparatus 100 according to an embodiment is shown, which includes a beam shaping system 102, an illumination system 104, and a projection system 106. The beam shaping system 102, the illumination system 104, and the projection system 106 are respectively arranged in a vacuum housing, and the vacuum housing can be evacuated by means of a vacuuming device (not shown in more detail). The vacuum housing is surrounded by a machine room (not shown in more detail) in which, for example, a driving device for mechanically moving and / or adjusting the optical element is provided. In addition, an electric controller and the like can also be provided in the machine room.

[0037] The beam shaping system 102 includes an EUV light source 108, a collimator 110, and a monochromator 112. As the EUV light source 108, for example, a plasma source or a synchrotron may be provided, which emits radiation in the EUV range (extreme ultraviolet ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com