Forming method of transistor

A technology of transistors and graphics, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high production cost and complicated production process, and achieve the effect of reducing production cost, simple forming process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] At present, SOI substrates are used as substrates in the production of fully depleted semiconductor-on-insulator transistors, and some fully depleted semiconductor-on-insulator transistors. The thickness uniformity is poor.

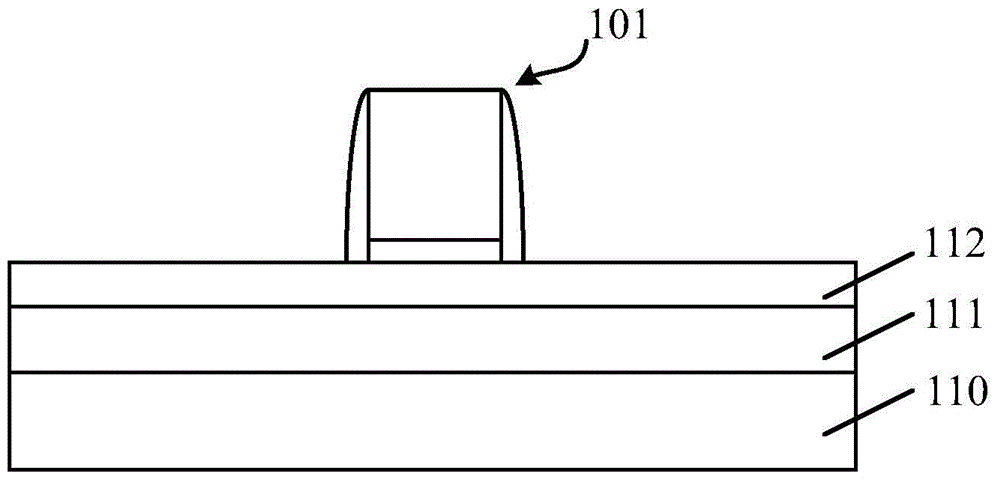

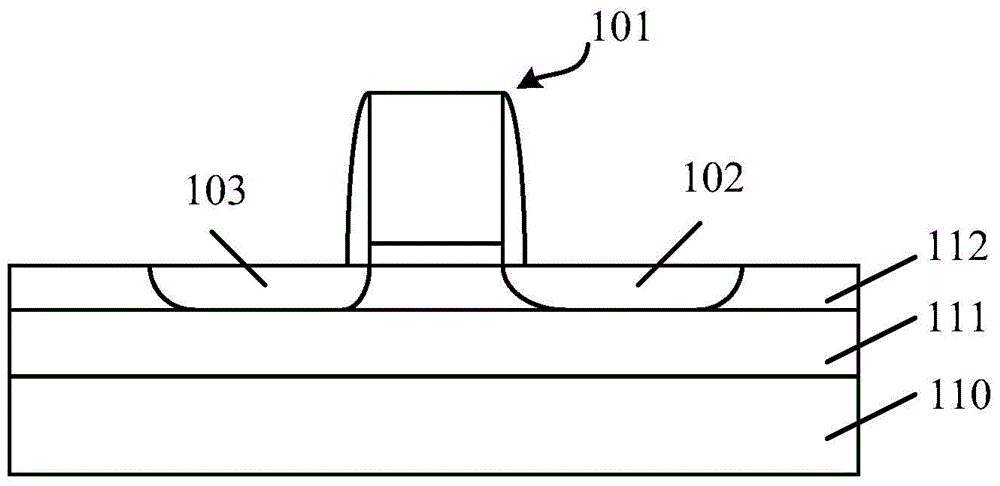

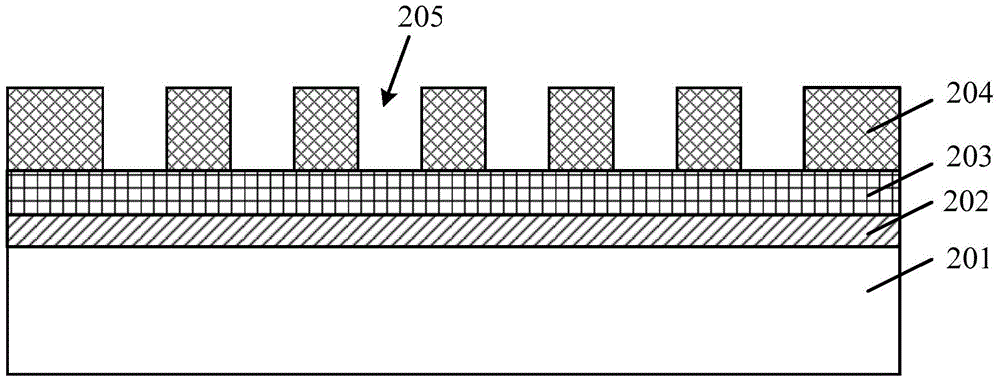

[0039]To this end, the present invention provides a method for forming a transistor, forming a first semiconductor layer and a second semiconductor layer on a substrate, etching the first semiconductor layer and the second semiconductor layer to form a semiconductor pattern, and removing the second semiconductor pattern The first semiconductor pattern at the bottom is formed into a cavity, and then an oxidation process is performed to form an oxide layer on the sidewall and bottom of the second semiconductor pattern and the surface of the substrate, and the oxide layer fills the cavity, and then the second A gate structure is formed on the surface of the two semiconductor patterns. The oxide layer is used as an insulating layer between the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com