Preparing method of KNN piezoelectric nanofiber flexible electricity generating element

A potassium sodium niobate, nanofiber technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, fiber processing, heating/cooling fabrics, etc., can solve the problems of high temperature processing and incompatibility of flexible substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

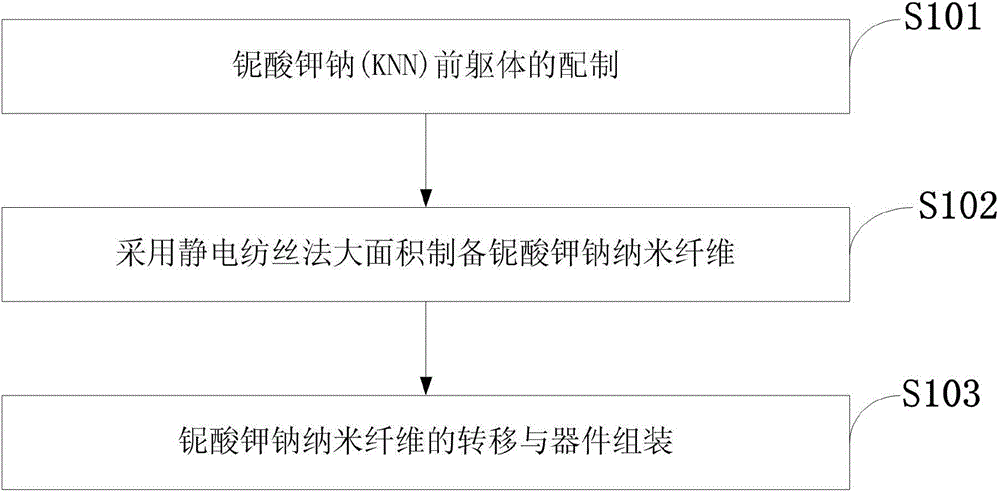

[0102] Such as figure 1 As shown, the preparation method of the potassium sodium niobate piezoelectric nanofiber flexible power generation element of the embodiment of the present invention comprises the following steps:

[0103] S101: Preparation of potassium sodium niobate (KNN) precursor;

[0104] S102: Prepare potassium sodium niobate nanofibers in large area by electrospinning method;

[0105] S103: Transfer and device assembly of potassium sodium niobate nanofibers.

[0106] Concrete steps of the present invention:

[0107] According to the embodiment of the present invention, a method for preparing a flexible piezoelectric power generation element based on potassium sodium niobate lead-free piezoelectric nanofibers, the steps of the flexible piezoelectric power generation element method are as follows:

[0108] Step 1: the preparation of potassium sodium niobate (KNN) precursor:

[0109] 1) Dissolve 0.1 to 0.2 parts by weight of potassium acetate and 0.15 to 0.3 pa...

Embodiment 1

[0157] Example 1: The preparation of a flexible piezoelectric power generation element based on potassium sodium niobate lead-free piezoelectric nanofibers, the steps of the preparation method are as follows:

[0158] Step 1: the preparation of potassium sodium niobate (KNN) precursor:

[0159] 1) Dissolve 0.12 parts by weight of potassium acetate and 0.16 parts by weight of sodium acetate trihydrate in a mixture of 4.0 parts by weight of ethylene glycol methyl ether and glacial acetic acid, the molar ratio of ethylene glycol methyl ether and glacial acetic acid is 5:1, and then drop Add 1.0 parts by weight of acetylacetone, and perform magnetic stirring for 10 hours after sealing to obtain solution A;

[0160] 2) Under the protection of dry nitrogen, dissolve 0.6 parts by weight of niobium ethylate in 4.0 parts by weight of ethylene glycol methyl ether and glacial acetic acid mixture, the molar ratio of ethylene glycol methyl ether and glacial acetic acid is 5:1, and then add...

Embodiment 2

[0179] Example 2: The preparation of a flexible piezoelectric power generation element based on potassium sodium niobate lead-free piezoelectric nanofibers, the steps of the preparation method are as follows:

[0180] Step 1: the preparation of potassium sodium niobate (KNN) precursor:

[0181] 1) Dissolve 0.12 parts by weight of potassium acetate and 0.16 parts by weight of sodium acetate trihydrate in a mixture of 4.0 parts by weight of ethylene glycol methyl ether and glacial acetic acid, the molar ratio of ethylene glycol methyl ether and glacial acetic acid is 5:1, and then drop Add 1.0 parts by weight of acetylacetone, and perform magnetic stirring for 10 hours after sealing to obtain solution A;

[0182] 2) Under the protection of dry nitrogen, dissolve 0.6 parts by weight of niobium ethylate in 4.0 parts by weight of ethylene glycol methyl ether and glacial acetic acid mixture, the molar ratio of ethylene glycol methyl ether and glacial acetic acid is 5:1, and then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com