A method for predicting flowing temperature of coal ash

A technology of flowing temperature and coal ash, which is applied in the field of soft measurement to achieve the effects of high accuracy, improved analysis efficiency and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

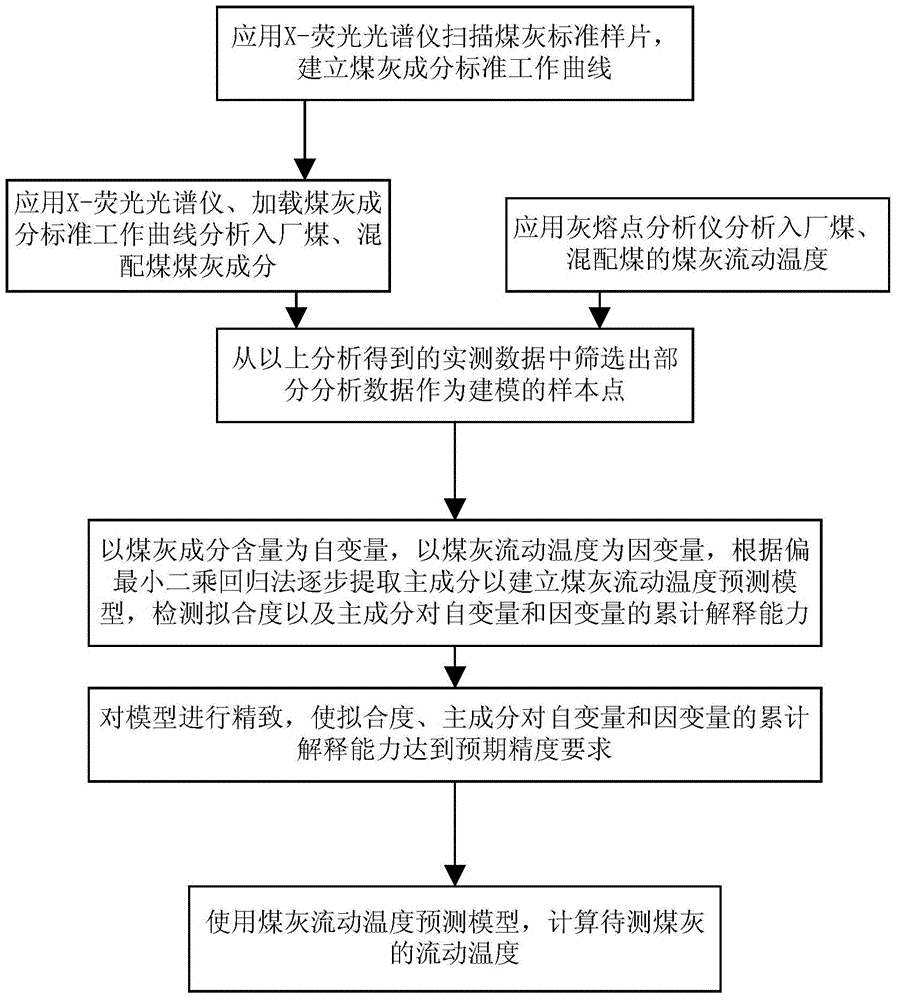

[0034] According to an embodiment of the present invention, a method for predicting the flow temperature of coal ash is provided. refer to figure 1 , the method includes the following steps:

[0035] Step 1: Establish standard working curve of coal ash composition

[0036] Firstly, several coal ash standard samples with a certain gradient distribution of each element content are selected, and the content of each component in the coal ash is determined through repeated determination and calibration by chemical method, and these coal ash standard samples are pressed into standard samples.

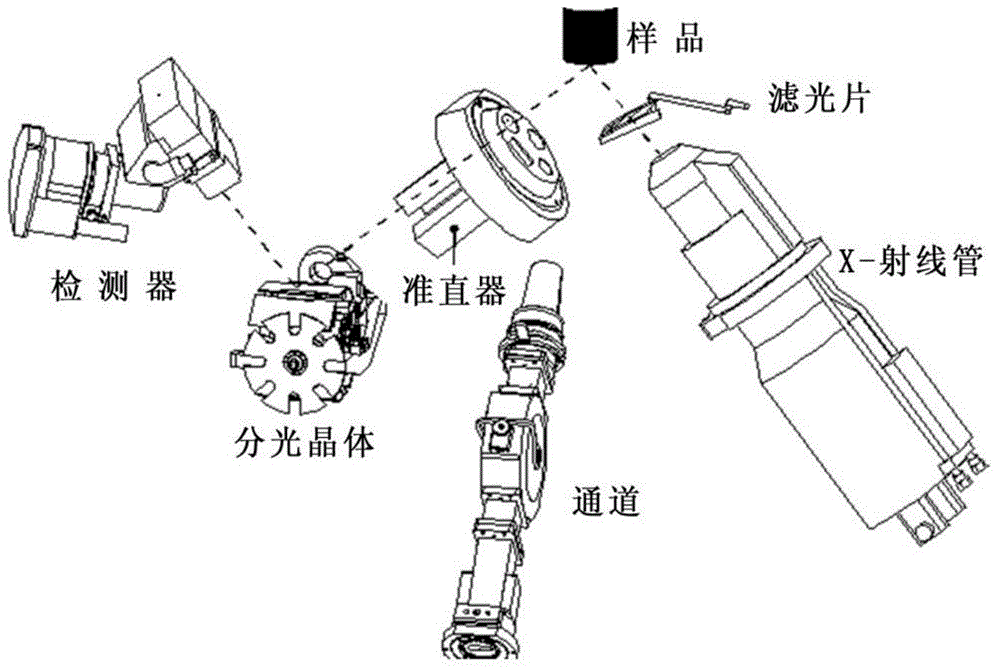

[0037] Next, adjust the working conditions of the X-fluorescence spectrometer, use the X-fluorescence spectromet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com