Method for measuring surface tension coefficient of liquid through liquid drainage of semi-spherical shell with bottom hole

A liquid surface tension, liquid measurement technology, applied in the direction of surface tension analysis, etc., can solve the problems of inaccurate measurement of liquid column height, low measurement accuracy, difficult coordinate values, etc., to achieve simple structure, reduce measurement range and accuracy. Requirement, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

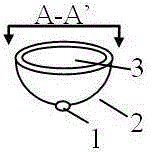

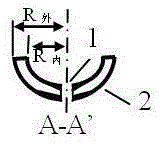

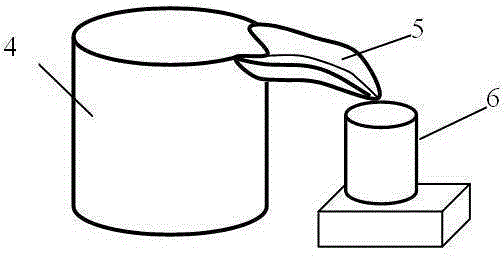

[0008] A hollow (hollow) hemispherical shell 2, sealed by two hemispherical surfaces with a common center, the radius of the inner sphere is R 内 , the radius of the outer sphere is R 外 , the bottom of the hollow hemispherical shell 2 has a through hole 1, because it is a hemispherical shell, that is, the radius of the outer circle of the ring where the hemispherical shell opening 3 is located is R 外 , the radius of the inner circle is R 内 , the outer side of the hemispherical shell 2 and the inner side of the outer side, the best design is that the material of the bottom is thick and the material of the upper end is thin (the deformation occurs inside the cavity surrounded by the inner and outer hemispherical surfaces, and does not affect the hemispherical shape of the hemispherical shell 2 outside The shape of the surface), and distributed symmetrically about the central axis (rotating body), such as figure 2 Shown, just make its center of gravity shift to the bottom of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com