Titanium-based lead dioxide anode with intermediate layer made of modified TiO2 nanotube arrays, preparation method and applications thereof

A nanotube array, lead dioxide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of easy detachment, low electrocatalytic efficiency, and unreliable coating, to increase the degree of bonding, strong Electrochemical oxidation ability, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] One of the present embodiment to modify TiO 2 A method for preparing a titanium-based lead dioxide anode with a nanotube array as an intermediate layer. The specific preparation steps are as follows:

[0032] (1) Take a rectangular Ti plate with a size of 30mm×20mm and a thickness of 0.8mm. Polish it step by step with 180-mesh, 360-mesh, and 500-mesh sandpaper until smooth, wash it with deionized water, acetone, and methanol for 15 minutes, and then use Wash with ultrapure water for 3 times, then place the Ti plate in 50mL mixed acid solution (HF:HNO 3 :H 2 O, 1:4:5, V:V:V) etch for 10 min, and then clean the etched Ti plate with ultrapure water;

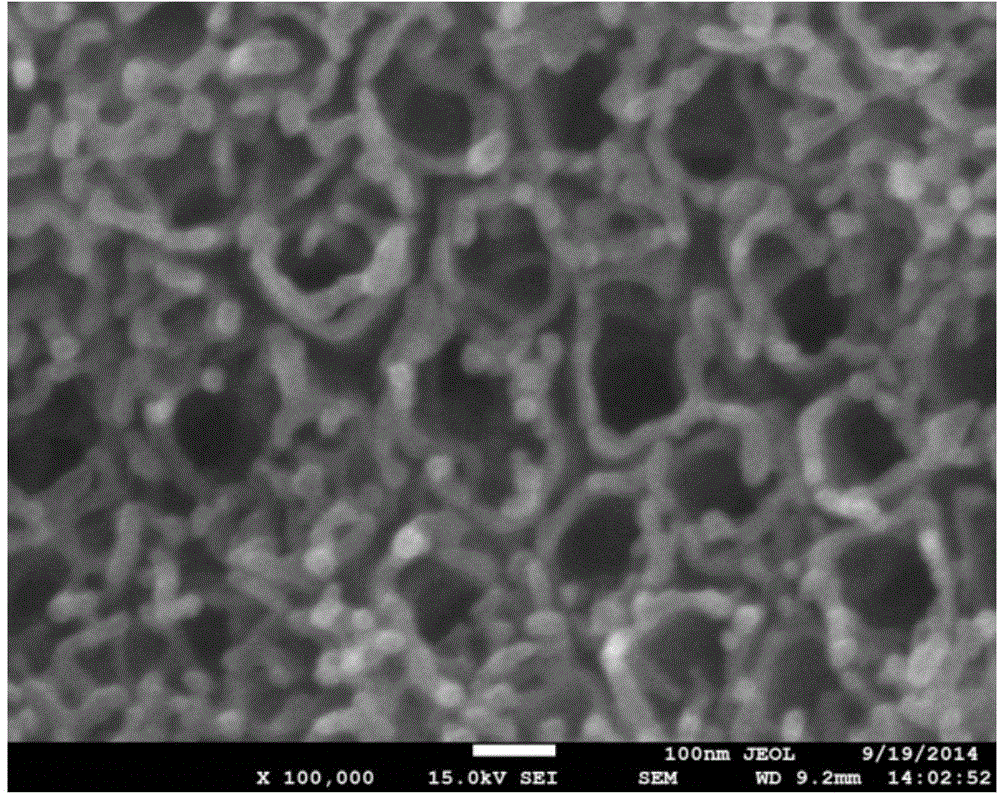

[0033] (2) Preparation of TiO by anodic oxidation 2 -NTs electrode: place the volume ratio HF: acetic acid: H with the titanium plate pretreated through step (1) as the anode and cathode 2 In the solution with O ratio of 0.04:1:8, the distance between cathode and anode is 1.0cm, the constant voltage is 40V, and the reaction...

Embodiment 2

[0039] A kind of Ag in this embodiment 2 O modified TiO 2 A method for preparing a titanium-based lead dioxide anode with a nanotube array as an intermediate layer. The specific preparation steps are as follows:

[0040] (1) Take a rectangular Ti plate with a size of 30mm×20mm and a thickness of 0.8mm. Polish it step by step with 180-mesh, 360-mesh, and 500-mesh sandpaper until smooth, wash it with deionized water, acetone, and methanol for 15 minutes, and then use Wash with ultrapure water for 3 times, then place the Ti plate in 50mL mixed acid solution (HF:HNO 3 :H 2 O, 1:4:5, V:V:V) etch for 10 min, and then clean the etched Ti plate with ultrapure water;

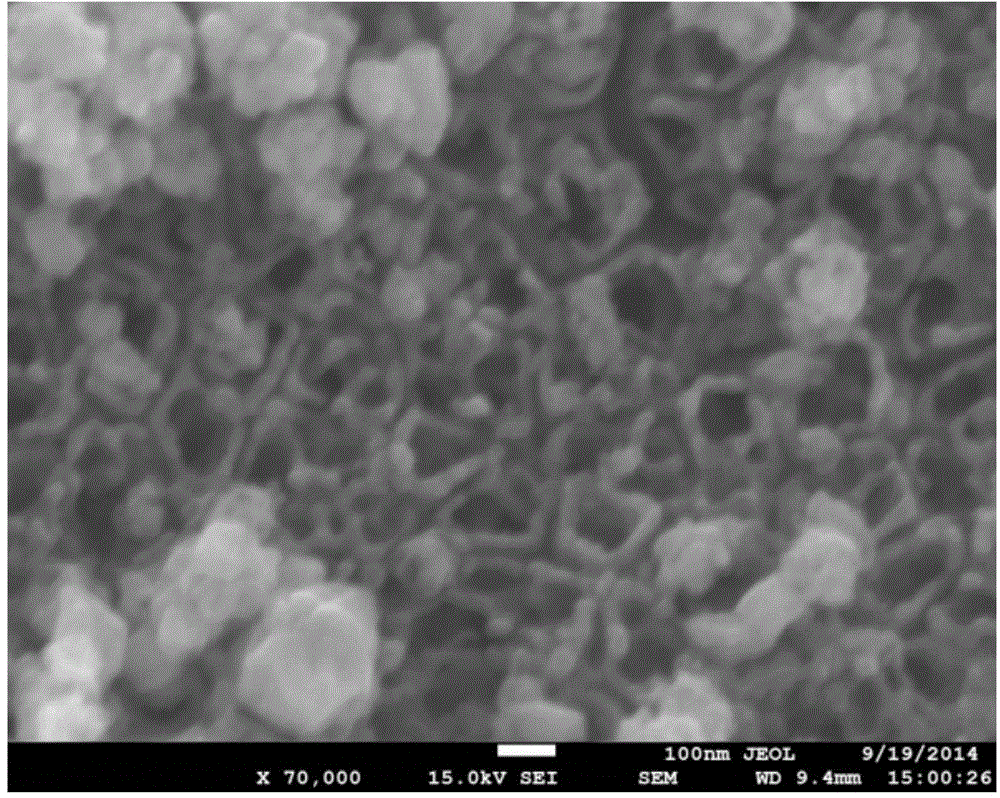

[0041] (2) Preparation of TiO by anodic oxidation 2 -NTs electrode: place the volume ratio HF: acetic acid: H with the titanium plate pretreated through step (1) as the anode and cathode 2 In the solution with O ratio of 0.04:1:8, the distance between cathode and anode is 1.5cm, the constant voltage is 60V, and the ...

Embodiment 3

[0046] One of the present embodiment to modify TiO 2 A method for preparing a titanium-based lead dioxide anode with a nanotube array as an intermediate layer. The specific preparation steps are as follows:

[0047] (1) Take a rectangular Ti plate with a size of 30mm×20mm and a thickness of 0.8mm. Polish it step by step with 180-mesh, 360-mesh, and 500-mesh sandpaper until smooth, wash it with deionized water, acetone, and methanol for 15 minutes, and then use Wash with ultrapure water for 3 times, then place the Ti plate in 50mL mixed acid solution (HF:HNO 3 :H 2 O, 1:4:5, V:V:V) etch for 10 min, and then clean the etched Ti plate with ultrapure water;

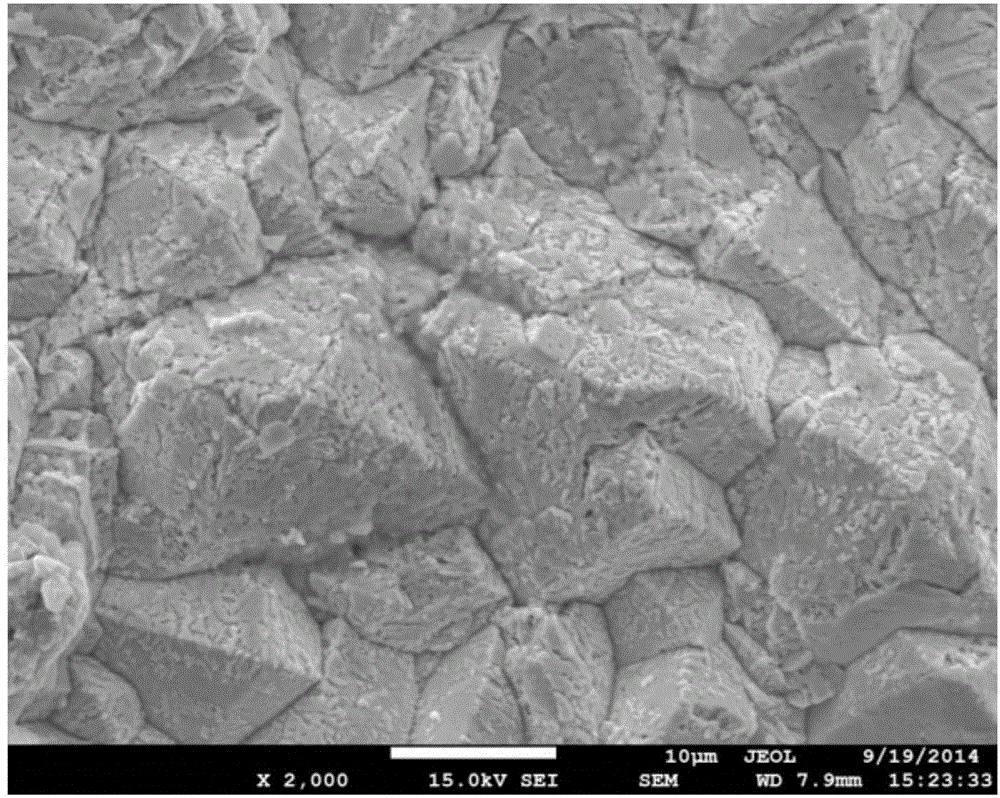

[0048] (2) Preparation of TiO by anodic oxidation 2 -NTs electrode: place the volume ratio HF: acetic acid: H with the titanium plate pretreated through step (1) as the anode and cathode 2 In a solution with O ratio of 0.04:1:8, the distance between cathode and anode is 1cm, the constant voltage is 20V, and the reaction tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com