Hard alloy and preparation method thereof

A technology of cemented carbide and hard phase, which is applied in the field of powder metallurgy, can solve the problems of difficult application of wear resistance and good toughness, and the lack of cubic phase gradient structure on the surface of ultra-fine grains. Effects of thermal crack growth ability, excellent wear and oxidation resistance, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

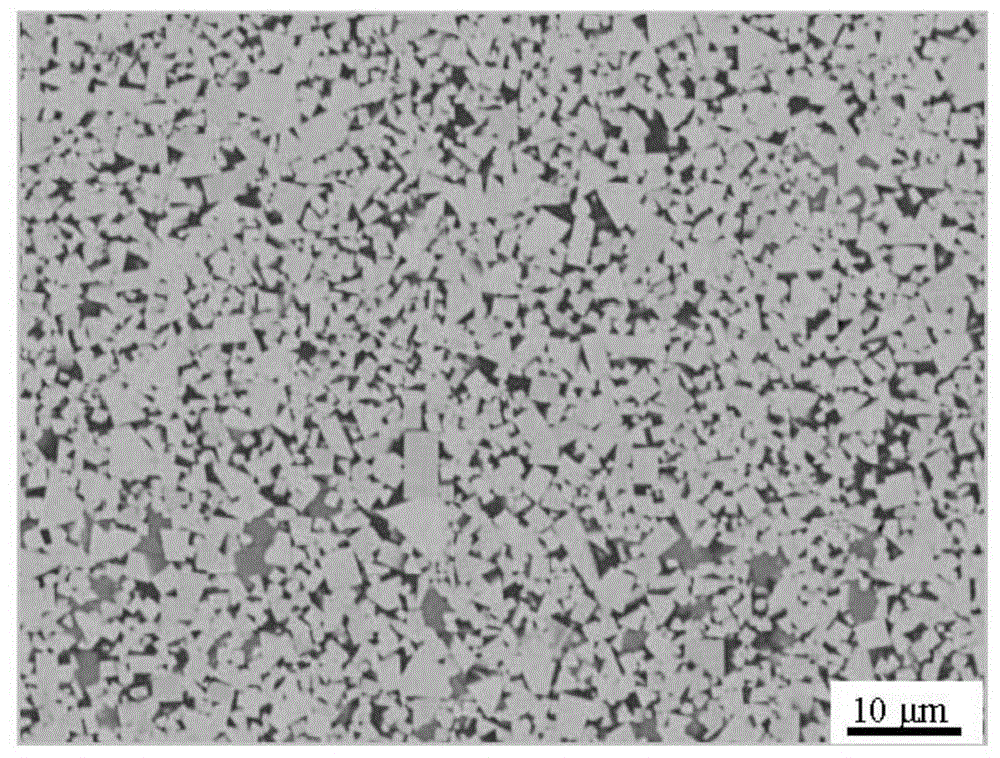

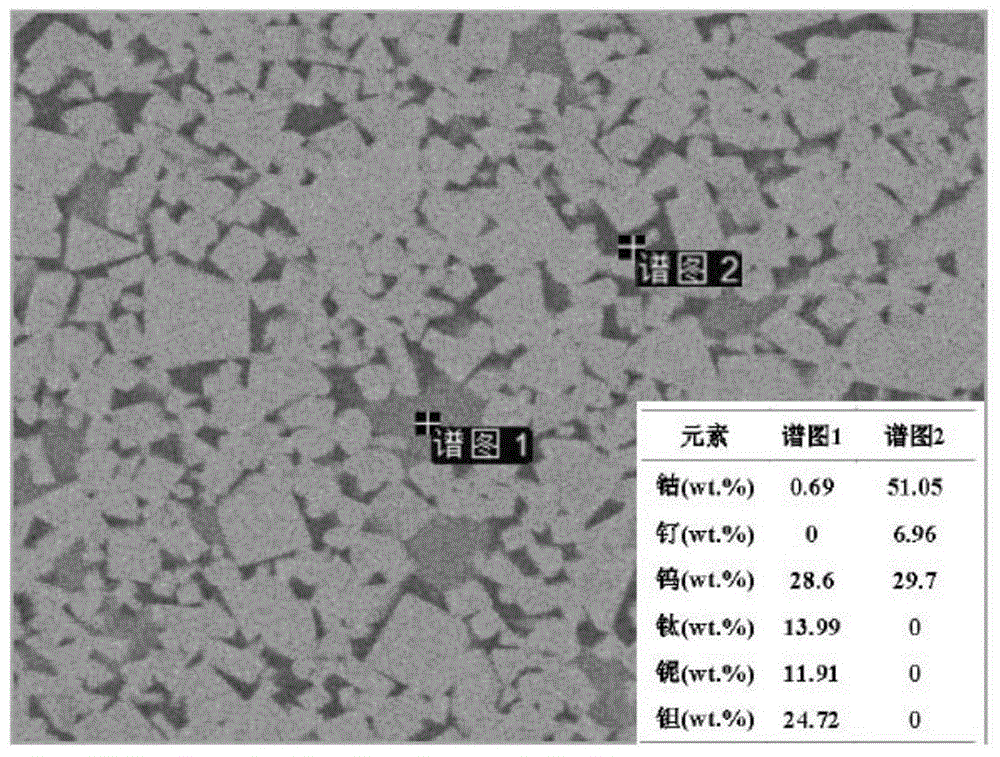

Embodiment 1

[0040] A kind of cemented carbide, is the cemented carbide of gradient structure lacking cubic phase of surface layer, comprises binding phase, hard phase and grain growth inhibitor, and binding phase comprises Co and Ru as strengthening phase; Hard phase is WC and cubic phase compounds, where the cubic phase compounds are TiC, TiN and (Ta,Nb)C; the grain growth inhibitors are VC and Cr 3 C 2 , its specific percentage content is: Co: 8wt.%, Ru: 1.2wt.%, TiC: 0.8wt.%, TiN: 0.4wt.%, TaC: 0.6wt.%, NbC: 0.4wt.%, VC: 0.4wt.%, Cr 3 C 2 : 0.6 wt.%. The balance is WC, and the average particle size of WC is 0.4 μm.

[0041] The preparation method of above-mentioned cemented carbide, comprises the following steps:

[0042] Complete the raw material preparation according to the above ratio, wherein the particle size of Co powder is 0.8 μm, the particle size of Ru powder is 300 mesh, the particle size of TiC, TiN and (Ta, Nb)C is 1.5 μm, VC and Cr 3 C 2The particle size is 1.4 μm, ...

Embodiment 2

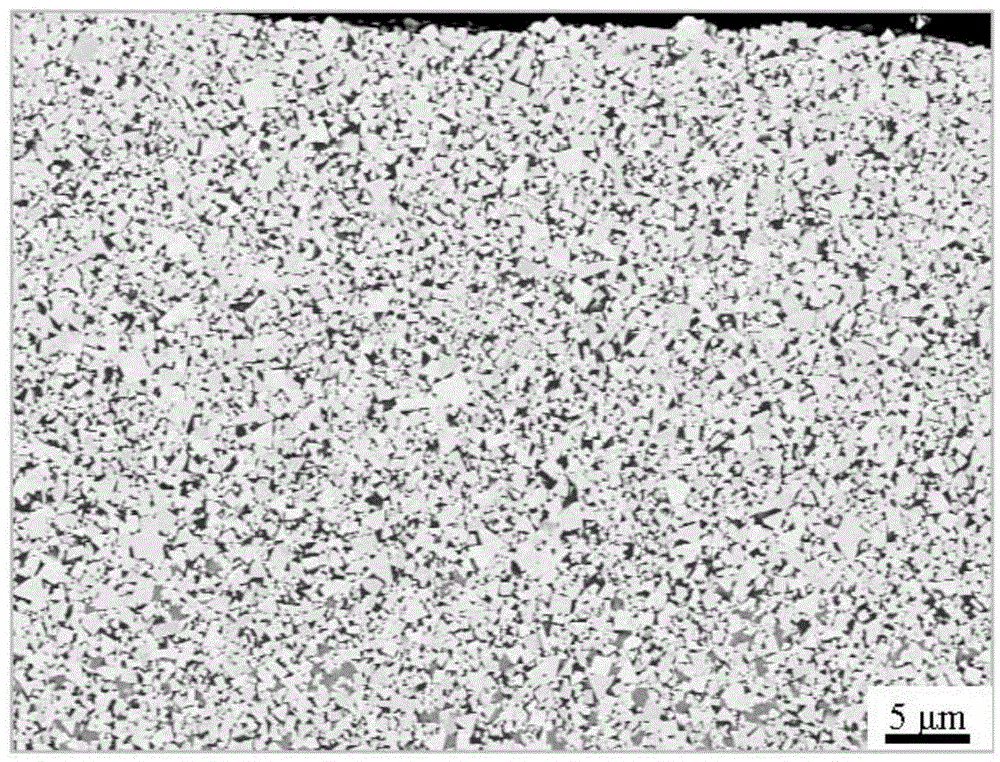

[0046] A kind of cemented carbide, is the cemented carbide of gradient structure lacking cubic phase of surface layer, comprises binding phase, hard phase and grain growth inhibitor, and binding phase comprises Co and Ru as strengthening phase; Hard phase is WC and cubic phase compounds, wherein the cubic phase compounds are TiC, TiN and (Ta, Nb)C, and their specific percentages are: Co: 10wt.%, Ru: 1.4wt.%, TiC: 1.4wt.%, TiN : 0.4wt.%, TaC: 2wt.%, NbC: 1wt.%, the balance is WC, and the average particle size of WC is 3μm.

[0047] The preparation method of above-mentioned cemented carbide, comprises the following steps:

[0048] The raw material preparation is completed according to the above ratio, wherein the particle size of Co powder is 0.8 μm, the particle size of Ru powder is 300 mesh, the particle size of TiC, TiN, TaC, and NbC is 1.5 μm, and 2wt.% PEG4000 is added as a forming agent. Carry out ball milling and mixing, dry after ball milling for 25 hours, and then perf...

Embodiment 3

[0053] A kind of cemented carbide, is the cemented carbide of gradient structure lacking cubic phase of surface layer, comprises binding phase, hard phase and grain growth inhibitor, and binding phase comprises Co and Ru as strengthening phase; Hard phase is WC And cubic phase compounds, where the cubic phase compounds are TiC, TiN and (Ta, Nb)C. , its specific percentage content is: Co: 10wt.%, Ru: 1.4wt.%, TiC: 2wt.%, TiN: 0.6wt.%, the balance is WC, and the average particle size of WC is 5 μm.

[0054] A kind of preparation method of above-mentioned cemented carbide, comprises the following steps:

[0055] Complete the raw material preparation according to the above ratio, wherein the particle size of Co powder is 0.8 μm, the particle size of Ru powder is 300 mesh, the particle size of TiC and TiN is 1.5 μm, and 2wt.% PEG4000 is added as a forming agent, and ball milling is carried out in a ball mill. Dry after 25 hours of ball milling. Then carry out compression molding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com