Pre-treating method for improving sugar conversion rate of lignocellulose

A technology of lignocellulose and lignocellulose, which is applied in the field of biomass resource conversion and utilization, can solve the problems of low conversion rate of enzymatic hydrolysis and cannot be satisfied, and achieve the effect of promoting enzymatic hydrolysis and simple and easy treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A pretreatment method for improving lignocellulose sugar conversion rate, the steps are as follows:

[0037] (1) remove the sundries in the corn stalks, then air-dry, pulverize and sieve the lignocellulose through a sieve with an aperture of 5 mm to obtain the cellulose raw material;

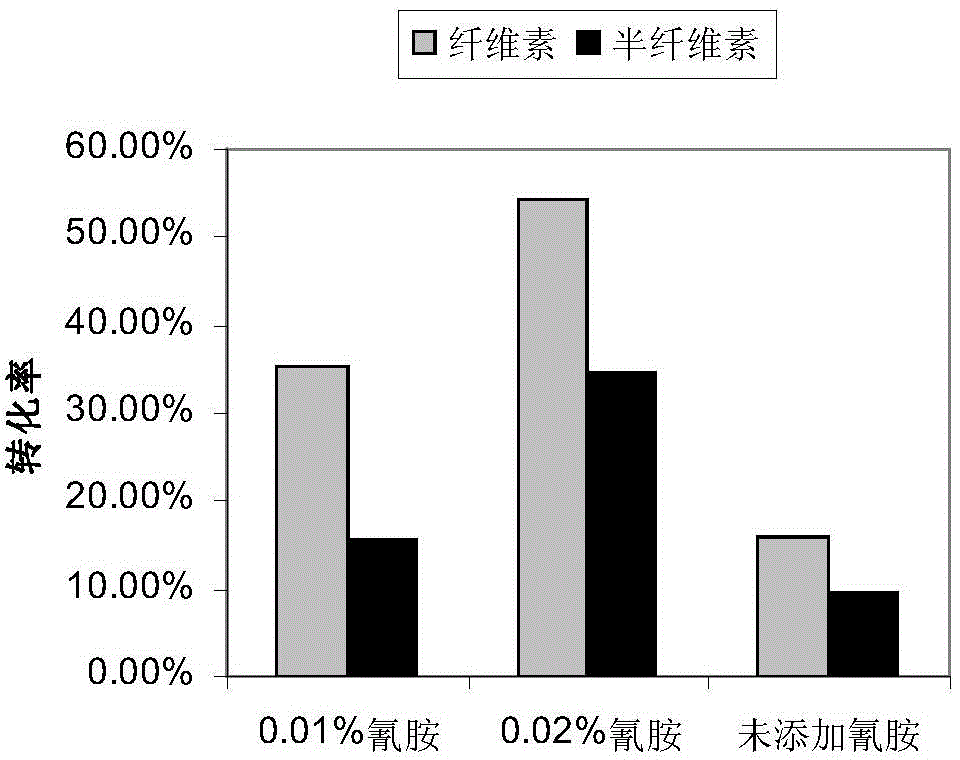

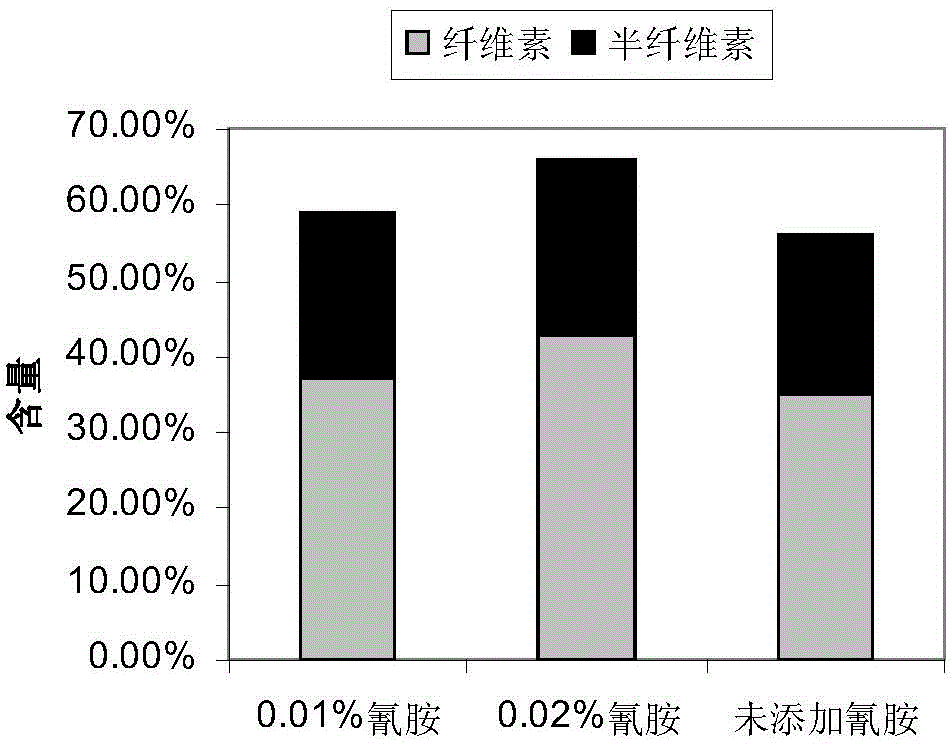

[0038] (2) Add the cellulose raw material to the NaOH solution, stir evenly, and then add H 2 o 2 Stir with the activator cyanamide evenly to obtain a mixed reaction solution, and the mixed reaction solution is stirred and reacted for 24 hours at 30° C. and at a shaker speed of 150 rpm to obtain pretreated lignocellulose;

[0039] In the mixed reaction solution, the amount of NaOH added is 0.15g·g -1 Lignocellulosic raw material, H 2 o 2 The dosage is 0.075g·g -1 For lignocellulosic raw materials, the final addition of cyanamide is 0.01g·g -1 Lignocellulosic raw material.

Embodiment 2

[0041] A pretreatment method for improving lignocellulose sugar conversion rate, the steps are as follows:

[0042] (1) remove the sundries in the bagasse, then air-dry, pulverize and sieve the lignocellulose through a sieve with an aperture of 5 mm to obtain the cellulose raw material;

[0043] (2) Add the cellulose raw material to the NaOH solution, stir evenly, and then add H 2 o 2 Stir with the activator cyanamide evenly to obtain a mixed reaction solution, and the mixed reaction solution is stirred and reacted for 24 hours at a stirring speed of 150 rpm at 30° C. to obtain pretreated lignocellulose;

[0044] In the mixed reaction solution, the amount of NaOH added is 0.15g·g -1 Lignocellulosic raw material, H 2 o 2 The dosage is 0.075g·g -1 For lignocellulosic raw materials, the final addition of cyanamide is 0.02g·g -1 Lignocellulosic raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com