Production method of environment-friendly polyester plasticizer

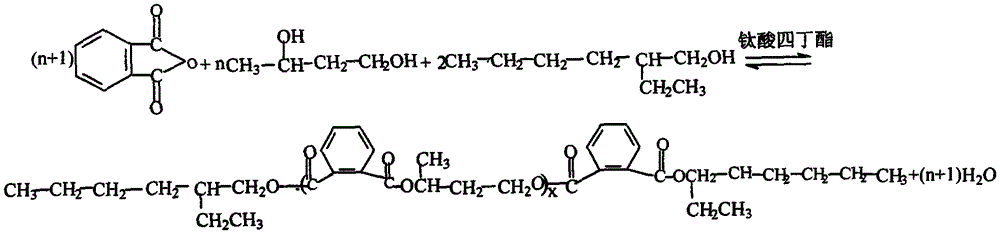

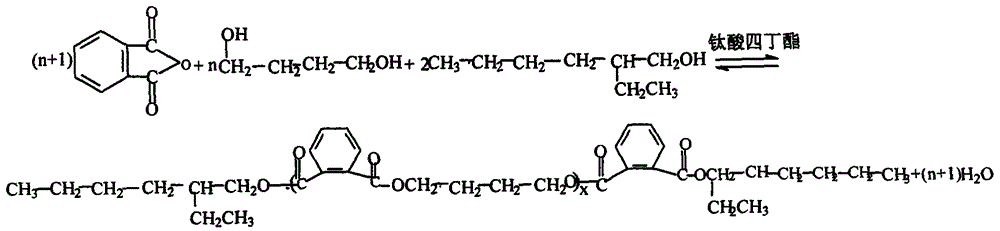

The technology of a polyester plasticizer and a production method is applied in the field of synthesizing phthalic anhydride diol polyester with tetra-n-butyl titanate as a catalyst, and can solve the problems of pollution, complicated process flow, poor product quality and the like, Achieve the effect of low product pollution, high product purity and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Poly-1,2-propylene glycol phthalate production method comprises the steps:

[0023] Add 1 mol (148.1 g) of phthalic anhydride, 85 ml (87.5 g) of 1,2 propylene glycol, and 2- Ethylhexanol 102ml (85g), add 1.2g tetra-n-butyl titanate as an esterification catalyst, pass high-purity nitrogen gas, stir and heat, when the temperature reaches 180-230°C, the reaction temperature is controlled at about 220°C, the reaction The time is 6 to 8 hours. When the reaction acid value is less than 10 mg KOH / g, the esterification reaction ends and the dealcoholization refining process is carried out. Atmospheric pressure dealcoholization is carried out first, the temperature is controlled at 140-190°C, and then vacuum distillation is carried out, the vacuum degree is controlled above 0.098Mpa, and the dealcoholization time is 2-3 hours. Take a sample to measure the acid value. When the acid value is 2mgKOH / When it is less than g, the dealcoholization refining process is finished, and th...

Embodiment 2

[0026] A kind of poly-1,3-butylene phthalate production method, comprises the steps:

[0027] Add 1.2mol (177.8g) of phthalic anhydride and 124ml (124.4g) of 1,3-butanediol into a 500ml glass four-necked flask equipped with a stirrer, a water separator, a spherical condenser and a thermometer. Terminal agent 2-ethylhexanol 122ml (102g), add 1.5g tetra-n-butyl titanate as an esterification catalyst, pass high-purity nitrogen, stir and heat, when the temperature reaches 180-230°C, the reaction temperature is controlled at 230°C ℃, the reaction time is 7-8 hours, when the reaction acid value is less than 10mg KOH / g, the esterification reaction is over, and the dealcoholization refining process is carried out. Atmospheric pressure dealcoholization is carried out first, the temperature is controlled at 160-200°C, and then vacuum distillation is carried out, the vacuum degree is controlled above 0.098Mpa, and the dealcoholization time is 3 hours. Take a sample to measure the acid va...

Embodiment 3

[0030] A kind of poly-1,4-butylene phthalate production method, comprises the steps:

[0031] Add 1.5mol (222.2g) of phthalic anhydride and 153ml (155.5g) of 1,4-butanediol into a 500ml glass four-necked flask equipped with a stirrer, a water separator, a spherical condenser and a thermometer. Terminal agent 2-ethylhexanol 153ml (128g), add 1.8g tetra-n-butyl titanate as an esterification catalyst, pass high-purity nitrogen, stir and heat, when the temperature reaches 180-230°C, the reaction temperature is controlled at 230°C ℃, the reaction time is 7-8 hours, when the reaction acid value is less than 10mg KOH / g, the esterification reaction is over, and the dealcoholization refining process is carried out. Atmospheric pressure dealcoholization is carried out first, the temperature is controlled at 180-210°C, and then vacuum distillation is carried out, the vacuum degree is controlled above 0.098Mpa, and the dealcoholization time is 3 hours. Take a sample to measure the acid va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com