Tailing aerated concrete block and preparation method thereof

A technology of air-entrained concrete and blocks, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. It can solve problems such as insufficient control of process parameters, difficulty in ensuring the quality of air-entrained concrete series products, and lack of raw materials. , to achieve the effect of improving quality, significant economic benefits and environmental protection value, and easy gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

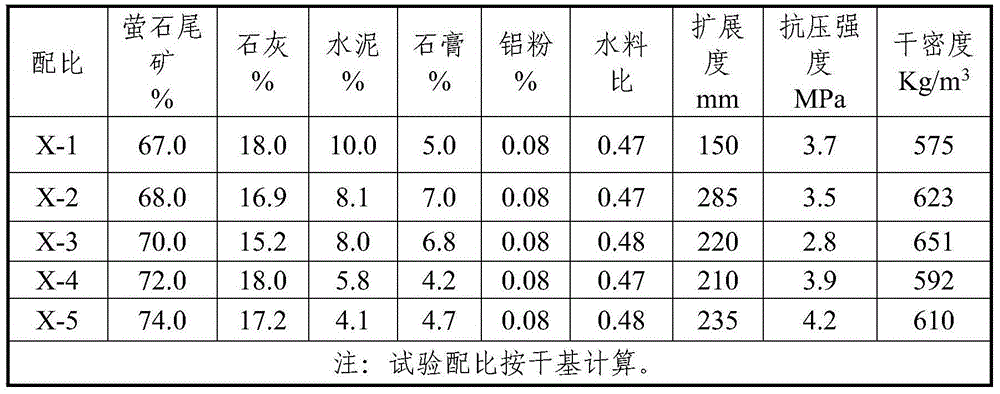

[0050] A tailings aerated concrete block, the raw materials of which are 70kg of fluorite tailings, 17kg of lime, 4.1kg of cement, 4.2kg of gypsum, and 0.05kg of aluminum powder.

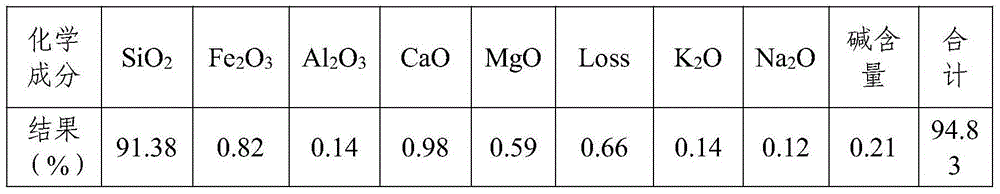

[0051] The fluorite tailings are 0.08mm powder, the powder sieve is 10%, and its specific surface area is 2800cm 2 / g.

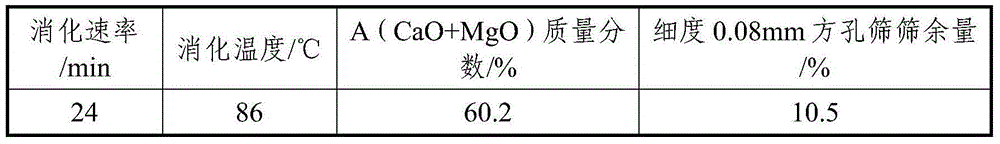

[0052] The lime is quicklime with a fineness of 0.08mm and a sieve residue of ≤10.5%.

[0053] The preparation method of the air-entrained concrete block comprises the following steps:

[0054] (1) Raw material processing and mixing: take raw materials according to the ratio, desulfurize the gypsum, and then obtain desulfurized gypsum with a sulfur trioxide content of 44.8%; put the fluorite tailings in a pulverizer for powder, and grind them into 0.08% mm powder, the powder sieve is 10%, and its specific surface area is 2800cm 2 / g, stand-by; then under normal temperature environment, mix the desulfurized gypsum and fluorite tailings powder, and use the stirring speed of 100r / ...

Embodiment 2

[0061] A tailings aerated concrete block, the raw material components (parts by weight) are 74kg of fluorite tailings, 18kg of lime, 10kg of cement, 5.1kg of gypsum, and 0.1kg of aluminum powder.

[0062] The fluorite tailings are 0.07mm powder, the powder sieve is 20%, and its specific surface area is 3300cm 2 / g.

[0063] The lime is quicklime with a fineness of 0.08mm and a sieve residue of ≤10.5%.

[0064] The preparation method of the air-entrained concrete block comprises the following steps:

[0065] (1) Raw material processing and mixing: take raw materials according to the ratio, desulfurize the gypsum, and then obtain desulfurized gypsum with a sulfur trioxide content of 44.8%; put the fluorite tailings in a pulverizer for powder, and grind them into 0.07% mm powder, the powder sieve is 20%, and its specific surface area is 3300cm 2 / g, stand-by; then at room temperature, mix desulfurized gypsum and fluorite tailings powder, and use a stirring speed of 120r / min to...

Embodiment 3

[0072] A tailings aerated concrete block, the raw materials of which are 72kg of fluorite tailings, 17.5kg of lime, 6kg of cement, 4.6kg of gypsum, and 0.08kg of aluminum powder.

[0073] The fluorite tailings are 0.08mm powder, the powder sieve is 15%, and its specific surface area is 3000cm 2 / g.

[0074] The lime is quicklime with a fineness of 0.08mm and a sieve residue of ≤10.5%.

[0075] The preparation method of the air-entrained concrete block comprises the following steps:

[0076] (1) Raw material processing and mixing: take raw materials according to the ratio, desulfurize the gypsum, and then obtain desulfurized gypsum with a sulfur trioxide content of 44.8%; put the fluorite tailings in a pulverizer for powder, and grind them into 0.075% mm powder, the powder sieve is 15%, and its specific surface area is 3000cm 2 / g, stand-by; then at room temperature, mix desulfurized gypsum and fluorite tailings powder, and use a stirring speed of 110r / min to stir for 1.5h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com