A reactor and method for removing organic matter in drinking water

A reactor and organic technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve the problems of increased floor space, low cost, and high ammonia removal efficiency, ensuring safety and achieving remarkable results. , the effect of convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

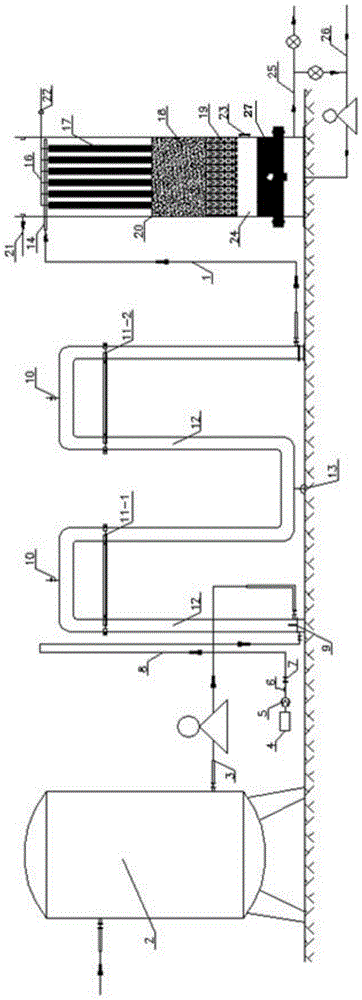

[0043] Such as figure 1 As shown, the reactor of the present invention for removing organic matter in drinking water includes a water storage tank 2 and a sand filter, and the sand filter is sequentially provided with a filter material layer 18, a supporting layer 19, a water distribution area 26 and a water outlet area 25 from top to bottom , the reactor also includes an ozone contact system located between the water storage tank 2 and the sand filter, and also includes a biologically activated carbon treatment area located in the sand filter, and a backwash system connected to the biologically activated carbon treatment area;

[0044] The ozone contact system comprises an ozone generator 4, a solenoid valve 5, a gas flow meter 6, a butterfly valve 7, a gas pipeline 8, a microporous aeration membrane 9, a deflation valve 10 and an ozone contact column 12; the ozone generator 4 passes through The pipeline is connected to the electromagnetic valve 5, the gas flow meter 6, the b...

Embodiment 2

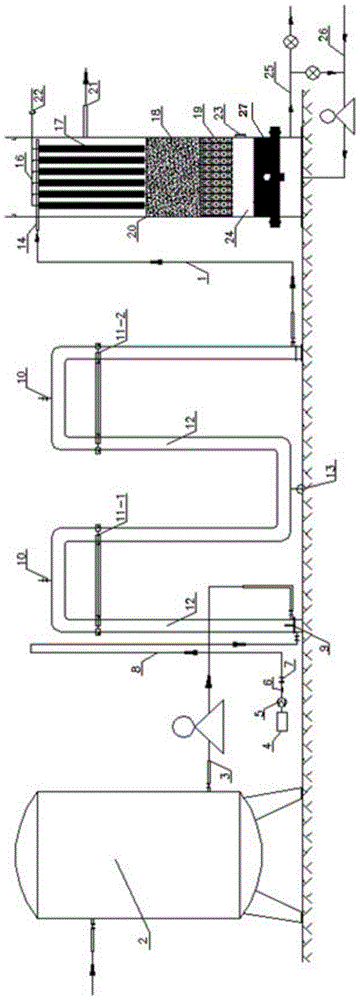

[0063] Such as figure 2 As shown, the reactor of the present invention for removing organic matter in drinking water includes a water storage tank 2 and a sand filter, and the sand filter is sequentially provided with a filter material layer 18, a supporting layer 19, a water distribution area 26 and a water outlet area 25 from top to bottom , the reactor also includes an ozone contact system located between the water storage tank 2 and the sand filter, and also includes a biologically activated carbon treatment area located in the sand filter, and a backwash system connected to the biologically activated carbon treatment area;

[0064] The ozone contact system comprises an ozone generator 4, a solenoid valve 5, a gas flow meter 6, a butterfly valve 7, a gas pipeline 8, a microporous aeration membrane 9, a deflation valve 10 and an ozone contact column 12; the ozone generator 4 passes through The pipeline is connected to the electromagnetic valve 5, the gas flow meter 6, the ...

Embodiment 3

[0083] The reactor for removing organic matter in drinking water of the present invention comprises a water storage tank 2 and a sand filter tank, and the sand filter tank is sequentially provided with a filter material layer 18, a supporting layer 19, a water distribution area 26 and a water outlet area 25 from top to bottom, and the reactor It also includes an ozone contact system located between the water storage tank 2 and the sand filter, a biologically activated carbon treatment area located in the sand filter, and a backwashing system connected to the biologically activated carbon treatment area;

[0084] The ozone contact system comprises an ozone generator 4, a solenoid valve 5, a gas flow meter 6, a butterfly valve 7, a gas pipeline 8, a microporous aeration membrane 9, a deflation valve 10 and an ozone contact column 12; the ozone generator 4 passes through The pipeline is connected to the electromagnetic valve 5, the gas flow meter 6, the butterfly valve 7 and one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com