A kind of preparation method of xonotlite type calcium silicate material

A technology of xonotlite and calcium silicate, which is applied in the field of preparation of xonotlite type calcium silicate materials, and can solve the problem that it is difficult to synthesize high-purity lightweight calcium silicate materials, and inappropriate addition of reinforcing materials such as fibers , affecting the quality of calcium silicate materials and other issues, to achieve the effect of benefiting popularization and application, short reaction time and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

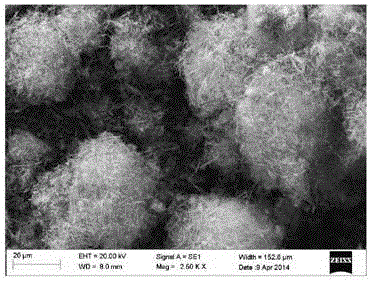

Image

Examples

example 1

[0033] The raw materials selected in the example of the present invention are silicon dioxide slag and quicklime after acid leaching magnesium from chrysotile fiber.

[0034] 1) Grinding the silica slag after acid leaching magnesium from chrysotile fiber with a silica content of 98.0% and quicklime with a CaO content of 90.0% to obtain active silica powder with a fineness of 100 mesh body and lime powder;

[0035] 2) with step 1) finely ground activated silica powder and lime powder, according to the chemical composition analysis result, according to SiO 2 / CaO molar ratio of 0.90 for batching, and placed in a mixer with a stirring device, according to the volume mass ratio of industrial water and high-activity silica powder and lime powder mixture of 12:1, add water and stir evenly, place Put it into a closed reaction kettle with a stirring device and keep it hydrothermally for 16 hours at a hydrothermal reaction temperature of 180°C and a pressure of 3.0MPa to obtain a synt...

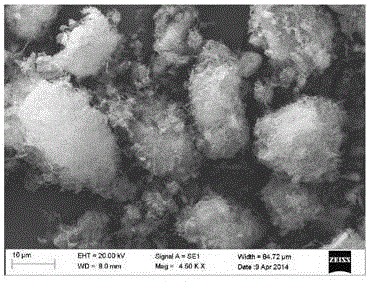

example 2

[0039] The raw materials selected in the example of the present invention are silica slag and slaked lime after chrysotile fiber and acid salt or ammonium salt are roasted to extract magnesium; its preparation method is basically the same as that of Example 1, and will not be repeated here.

[0040]The differences are:

[0041] 1) Grinding the chrysotile fiber with a silica content of 94.3%, the silica slag after roasting and extracting magnesium with acid salt or ammonium salt, and the slaked lime with a CaO content of 73.0%, respectively, to obtain a fineness of 80 Purpose Active silica powder and slaked lime powder;

[0042] 2) with step 1) finely ground activated silica powder and slaked lime powder, according to the chemical composition analysis result, according to SiO 2 / CaO molar ratio 1.25 for batching, and placed in a mixer with a stirring device, according to the volume mass ratio of industrial water and high-activity silica powder and lime powder mixture is 11:1, ...

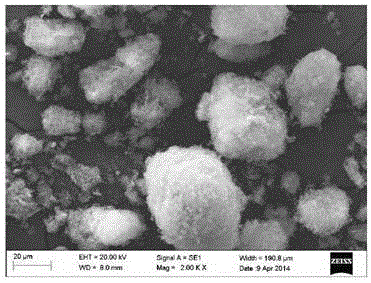

example 3

[0046] The raw materials selected in the example of the present invention are silica slag after acid leaching magnesium from serpentine tailings and caustic lime mud calcined powder at 1000°C; the preparation method is basically the same as that in Example 1, and will not be repeated here.

[0047] The differences are:

[0048] 1) The silica slag after acid leaching magnesium from serpentine tailings with a silica content of 89.7% and the calcined caustic lime mud calcined at 1000°C with a CaO content of 90.0% were respectively ground to obtain 200 mesh Activated silica powder and lime powder;

[0049] 2) Step 1) the finely ground high-activity silica powder and lime powder, according to the chemical composition analysis results, according to SiO 2 The / CaO molar ratio is 0.85 for batching, and placed in a mixer with a stirring device, according to the volume mass ratio of industrial water, high-activity silica powder and lime powder mixture of 15:1, add water and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com