Equipment for compacting softwood to hardwood

A kind of equipment and hardwood technology, which is applied in the field of equipment for compacting cork into hardwood, and achieves the effects of complete functions, high compaction effect, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

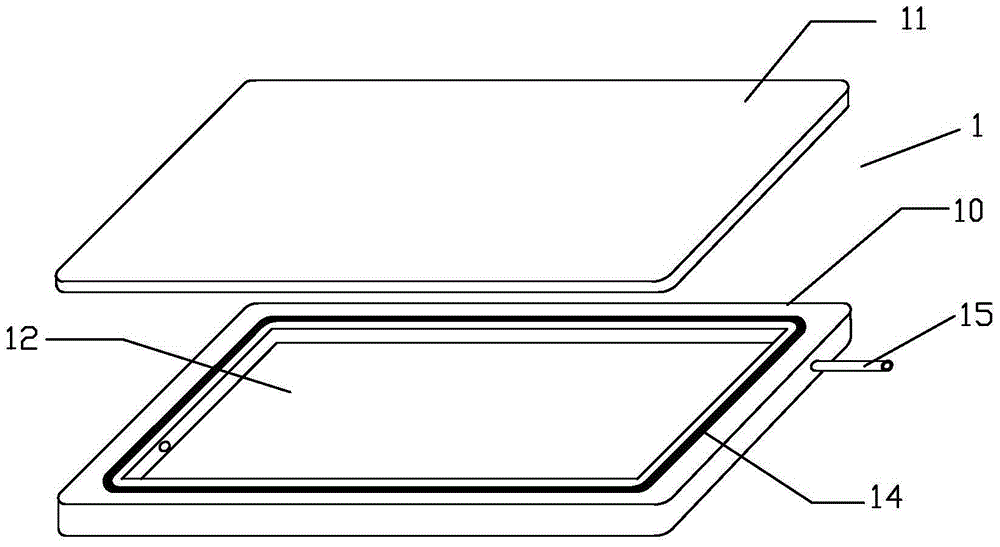

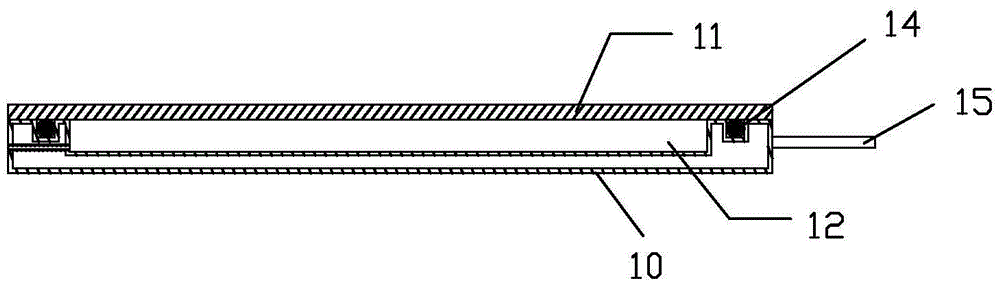

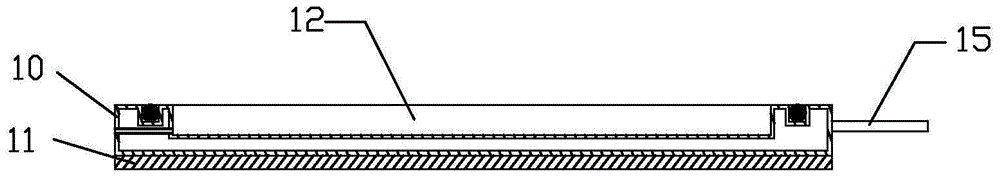

[0052] A device for compacting softwood into hardwood, figure 1 As shown, the hot pressing plate 1 is made of stainless steel, and the hot pressing plate 1 includes a plate body 10 and a pressing plate 11. The upper surface of the plate body 10 is provided with a rectangular groove 12 for holding wood, and the side wall of the groove 12 is provided with a discharge The nozzle 15 for cooling water and impurities, the pressing plate 11 is arranged on the top of the disc body 10, and the pressing plate 11 can move vertically through the sliding mechanism arranged on the compact support 2; Push down snap fit, see figure 2 , The groove 12 forms a sealed space. The upper surface of the disc body 10 is provided with a groove around the groove 12, and a sealing rubber ring 14 is arranged in the groove. High temperature and high pressure compaction process.

[0053] This embodiment preferably uses an electric heating heat transfer oil system. At this time, the disc body 10 is a sea...

Embodiment 2

[0059] This embodiment is another embodiment of the present invention's equipment for compacting softwood into hardwood, and the difference from Example 1 is that, as Figure 8 As shown, the equipment of this embodiment also includes a lifting transmission device 6 that can move up and down, and is located at the front end of the compact support 2; The conveying platform 61 at the top; the bottom of the front end of the elevating conveying device 60 is also provided with a motor 62 . The lifting conveyor 6 adjusts the telescopic height according to the height of the hot plate 1 through the telescopic rod 60 , and moves the pretreated wood to the hot plate 1 through the horizontal movement of the conveying table 61 .

Embodiment 3

[0061] This embodiment is yet another embodiment of the device for compacting hardwood with softwood according to the present invention. The difference from Embodiment 1 lies in the structure of the hot plate 1, and the device also has a preheating support 4 and a steam injection system. 5 and the transmission mechanism, the lifting transmission device 6 is located at the front end of the preheating support 4.

[0062] Figure 9 As shown, the bottom of the groove 12 of the hot plate 1 of this embodiment and the position corresponding to the groove 12 on the bottom surface of the pressing plate 11 are all provided with a mesh bottom support 16; Steam inlet 17 in 12. Figure 10 Shown is a state view of the pressure plate 11 pressing down from the top of the disc body 10, Figure 11 It is shown that the bottom surface of the lower disc body 10 is fixed with the top surface of the upper laminated board 11 to form an integrated board body.

[0063] Such as Figures 12 to 14 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com